Flue gas guide system of large-sized spot-oriented commercial gas stove

A large pot stove, flue gas technology, applied in household stoves, household stoves/stoves, applications, etc., can solve the problems of large pot stove flue gas waste heat waste, low heat utilization rate, poor safety and stability, etc., to achieve the effect of oil fume removal Clean flue gas, high heat utilization rate, and improve the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

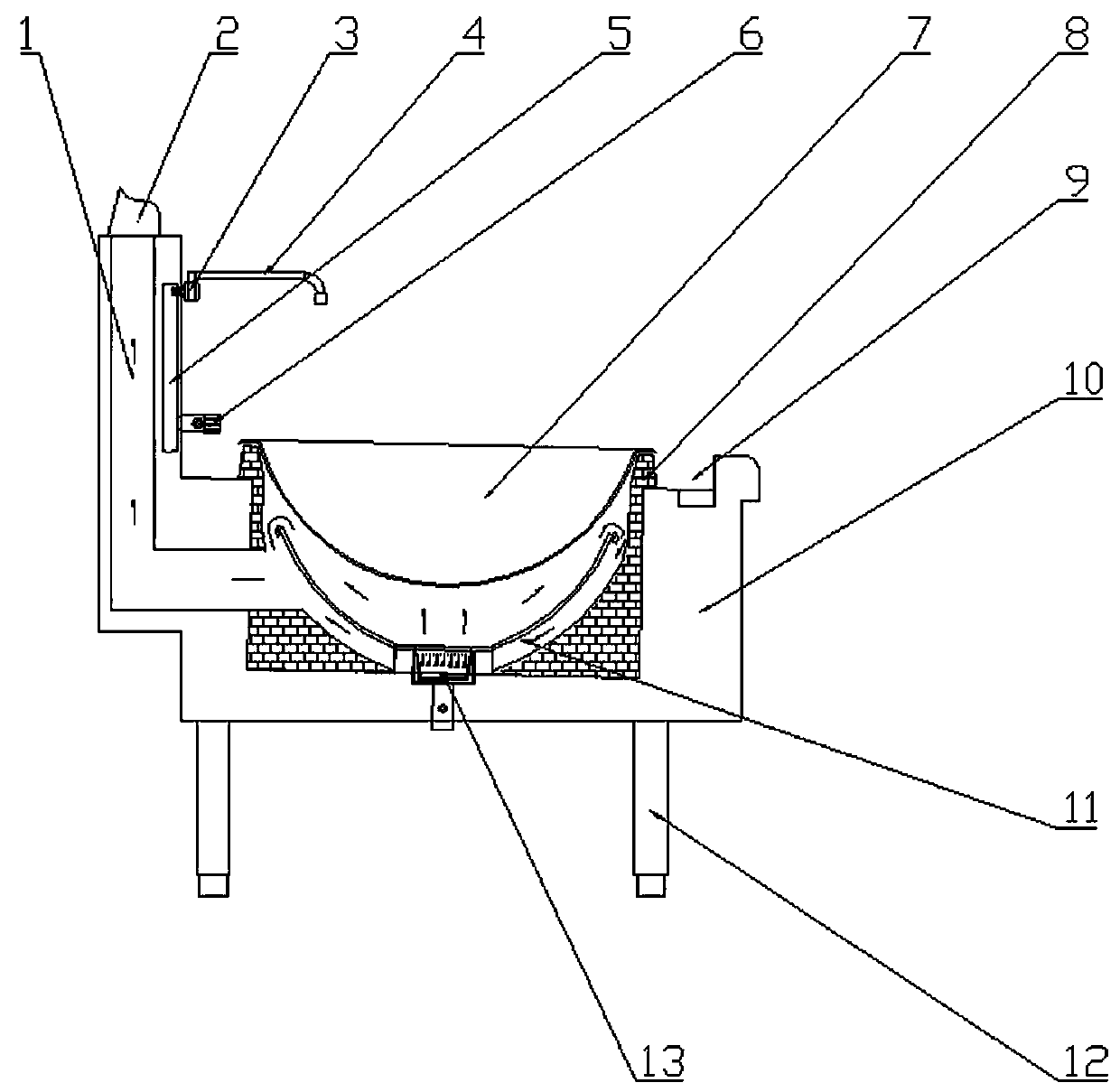

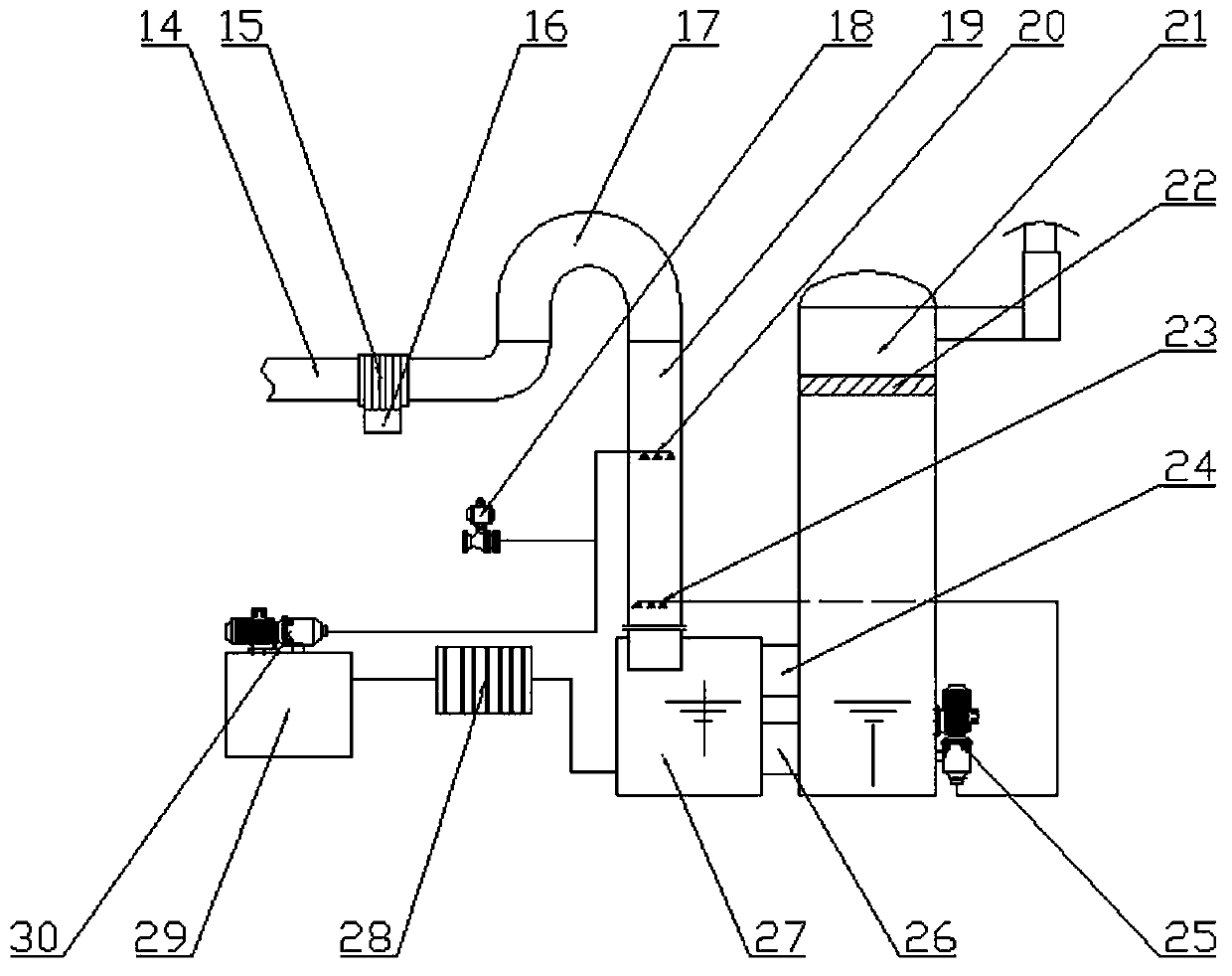

[0021] Example: such as figure 1 and figure 2 As shown, a flue gas diversion system for a large commercial gas-fired cooker includes a cooker frame 10, and four support legs 12 are arranged at the lower end of the cooker frame 10 in an equidistant rectangular array. The large pot stove frame 10 is provided with a cast iron cauldron 7, and the cast iron cauldron 7 and the large pot stove frame 10 are provided with a hearth 8 which is combined with the large pot stove frame 10, and the fire hearth 8 is made of bricks. Between the upper part of the hearth 8 and the upper part of the large cooker frame 10, there is a flame-retardant drainage groove 9 integrated with the large cooker frame 10, and the lower part of the cast iron cauldron 7 is provided with a socket that is socketed with the furnace 8 and extends out of the large cooker frame. The burner 13 at the lower end of 10 is provided with a flue gas deflector 11 socketed with the burner 13 between the burner 13 and the fur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap