Grease composition, preparation method and application thereof in preparation of mayonnaise

A technology for oil composition and mayonnaise, which is applied in the directions of application, edible oil/fat, food ingredients containing oil, etc., can solve problems such as affecting fat-soluble vitamins, human health hazards, taste problems, etc., so as not to affect the intake of nutrients , The effect of improving emulsion stability and increasing product shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

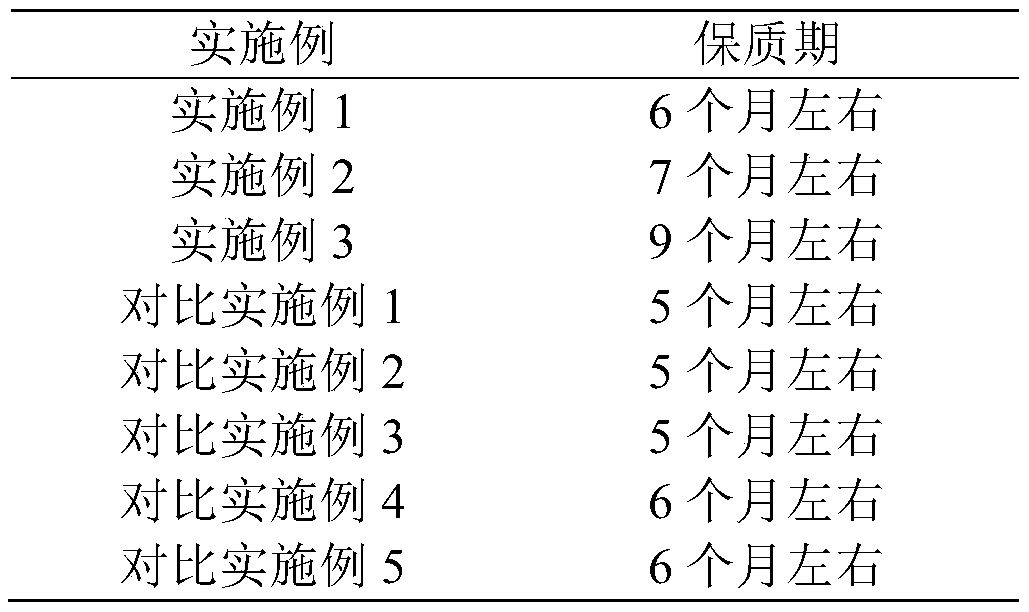

Embodiment 1

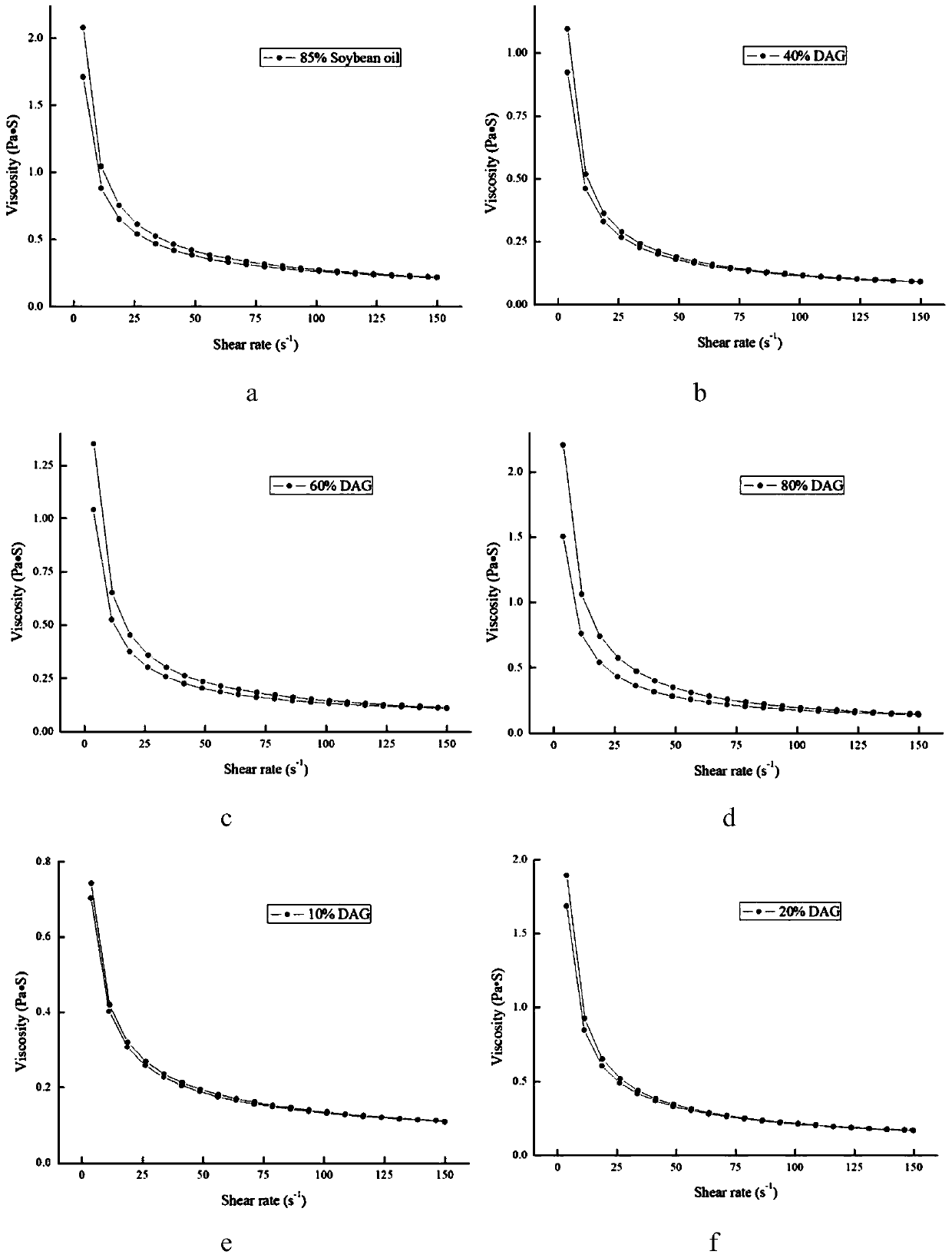

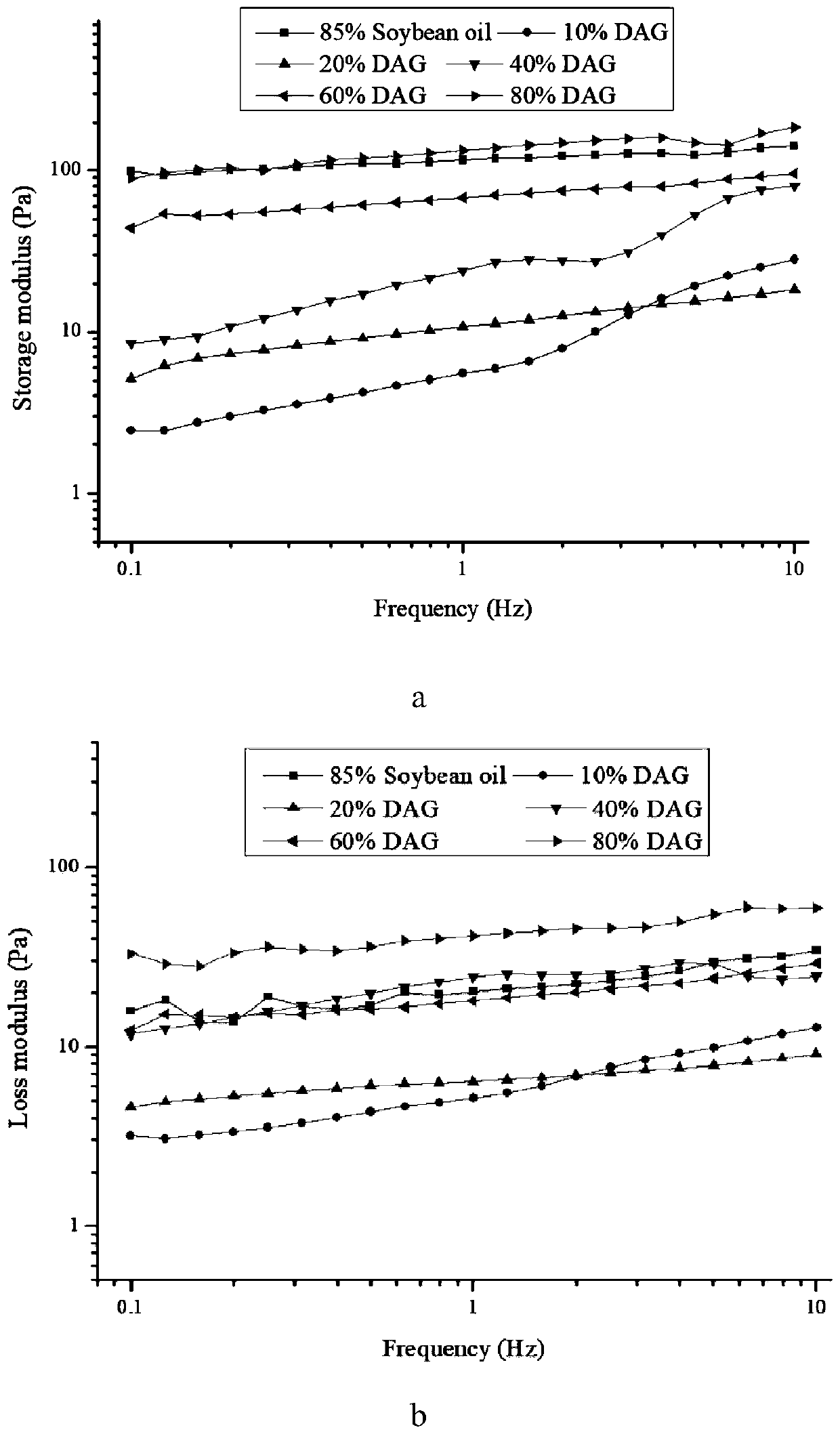

[0031] The preparation method of the oil composition: 40% soybean oil-based diglyceride, 45% soybean oil, 10% coconut oil and 5% sesame oil are uniformly mixed.

[0032] How to prepare mayonnaise:

[0033] The mayonnaise contains the following components: 70% oil composition, 20% water, 6% egg yolk and 4% vinegar.

[0034] The preparation method of said mayonnaise is as follows: first, water, vinegar and egg yolk are gently mixed to form a water phase, and then a certain amount of oil composition is gradually added to the water phase and whipped by a homogenizer to form a uniform emulsion . The stirring rate of the homogenizer is 12500rpm, the whipping time is 6min, and the temperature is 25±1°C.

[0035] Soybean oleyl diglyceride is produced by hydrolysis of soybean oil to produce soybean oleyl fatty acid, and then esterified with glycerin. The lipase AYS enzyme derived from Candida rugosa was selected for the hydrolysis reaction, and the Lipozyme RM IM enzyme (Novozyme) d...

Embodiment 2

[0038] The preparation method of the oil composition: 60% of soybean oil-based diglyceride, 25% of soybean oil, 10% of coconut oil and 5% of sesame oil are uniformly mixed.

[0039] How to prepare mayonnaise:

[0040] The mayonnaise contains the following components: 70% oil composition, 20% water, 6% egg yolk and 4% vinegar.

[0041] The preparation method of said mayonnaise is as follows: first, water, vinegar and egg yolk are gently mixed to form a water phase, and then a certain amount of oil composition is gradually added to the water phase and whipped by a homogenizer to form a uniform emulsion . The stirring rate of the homogenizer is 12500rpm, the whipping time is 6min, and the temperature is 25±1°C.

[0042] Soybean oleyl diglyceride is produced by hydrolysis of soybean oil to produce soybean oleyl fatty acid, and then esterified with glycerin. The lipase AYS enzyme derived from Candida rugosa was selected for the hydrolysis reaction, and the Lipozyme RM IM enzyme ...

Embodiment 3

[0045] The preparation method of the oil composition: 80% soybean oil-based diglyceride, 5% soybean oil, 10% coconut oil and 5% sesame oil are uniformly mixed.

[0046] How to prepare mayonnaise:

[0047] The mayonnaise contains the following components: 70% oil composition, 20% water, 6% egg yolk and 4% vinegar.

[0048] The preparation method of said mayonnaise is as follows: first, water, vinegar and egg yolk are gently mixed to form a water phase, and then a certain amount of oil composition is gradually added to the water phase and whipped by a homogenizer to form a uniform emulsion . The stirring rate of the homogenizer is 12500rpm, the whipping time is 6min, and the temperature is 25±1°C.

[0049] Soybean oleyl diglyceride is produced by hydrolysis of soybean oil to produce soybean oleyl fatty acid, and then esterified with glycerin. The lipase AYS enzyme derived from Candida rugosa was selected for the hydrolysis reaction, and the Lipozyme RM IM enzyme (Novozyme) de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com