A honeysuckle extraction method with high polysaccharide preservation rate and ultra-low temperature ultrafine pulverizer

A technology of ultrafine pulverizer and extraction method, which is applied in separation methods, chemical instruments and methods, solvent extraction, etc., and can solve the problems of polysaccharide extraction activity damage, time-consuming, low extraction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

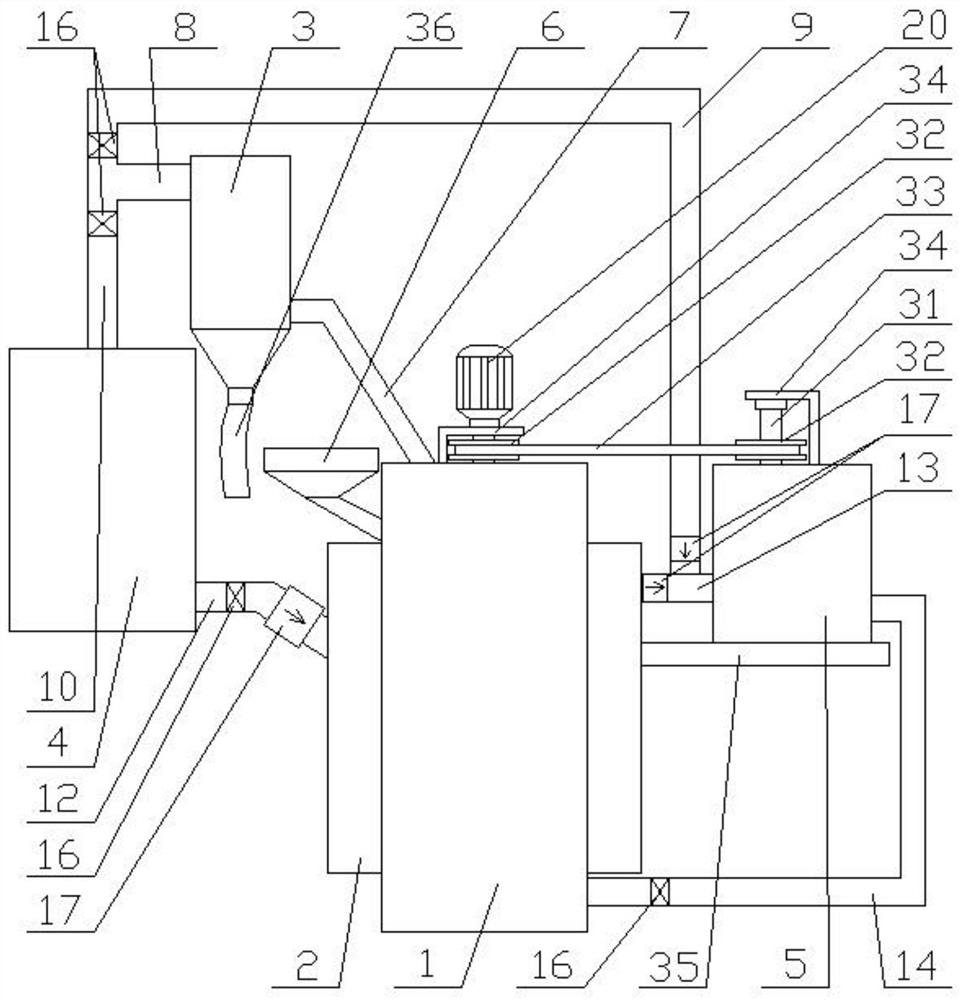

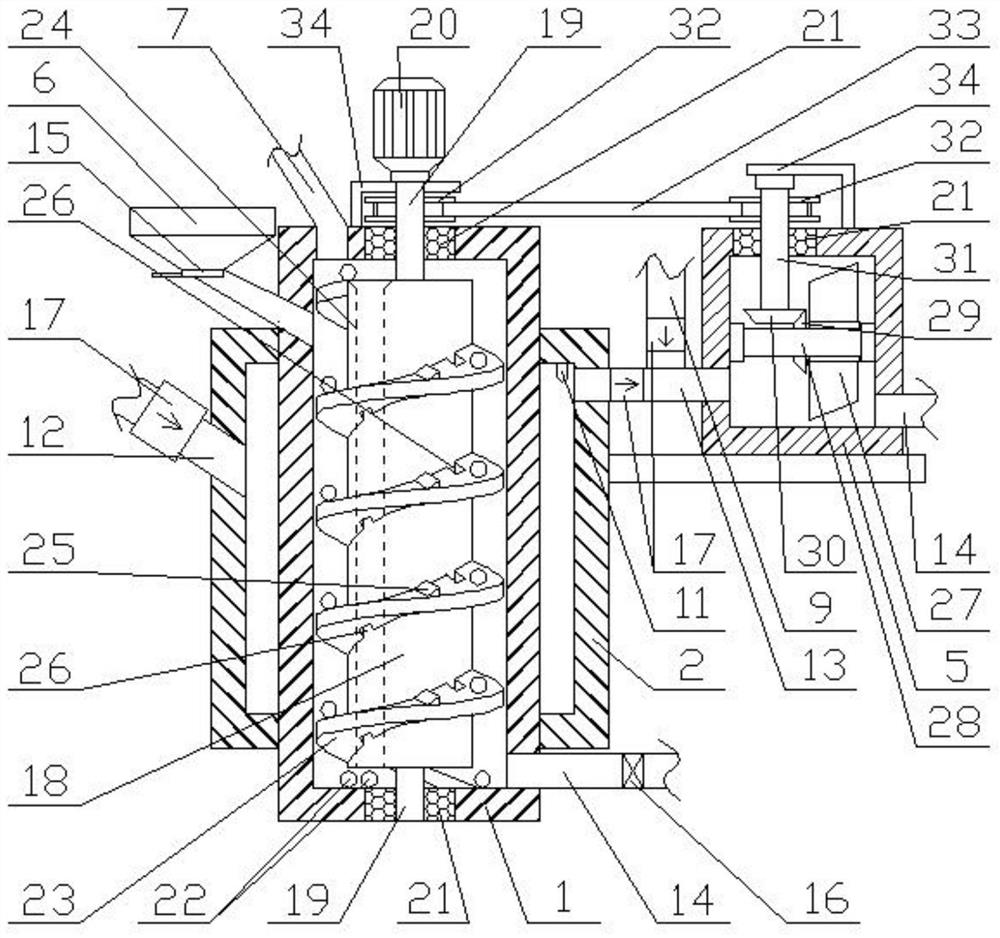

Image

Examples

Embodiment 1

[0043] A method for extracting honeysuckle with a high polysaccharide preservation rate and an ultra-low temperature ultrafine pulverizer, comprising the following steps:

[0044] S1. Raw material selection: select fresh honeysuckle, clean and cut;

[0045] S2. Vacuum drying of raw materials: vacuum freeze-drying the raw materials after cleaning and cutting in step S1;

[0046] S3, ultra-low temperature ultra-fine grinding: the raw material after vacuum drying in step S2 is subjected to ultra-low temperature ultra-fine grinding for 3 times, after each grinding process, powder samples are taken for particle size measurement, and the impact of grinding times on the quality of ultra-fine powder and soluble fiber is analyzed , to produce superfine powder;

[0047] S4, radio frequency assisted extraction: the superfine powder prepared in step S3 is mixed with acidic electrolyzed water with a pH value of 4.8, and assisted by a 27.12MHz radio frequency processor for 15 minutes, and ...

Embodiment 2

[0054] A method for extracting honeysuckle with a high polysaccharide preservation rate and an ultra-low temperature ultrafine pulverizer, comprising the following steps:

[0055] S1. Raw material selection: select fresh honeysuckle, clean and cut;

[0056] S2. Vacuum drying of raw materials: vacuum freeze-drying the raw materials after cleaning and cutting in step S1;

[0057] S3, ultra-low temperature ultra-fine grinding: the raw material after vacuum drying in step S2 is subjected to ultra-low temperature ultra-fine grinding for 3 times, after each grinding process, powder samples are taken for particle size measurement, and the impact of grinding times on the quality of ultra-fine powder and soluble fiber is analyzed , to produce superfine powder;

[0058] S4, radio frequency assisted extraction: mix the superfine powder prepared in step S3 with the acidic electrolyzed water with an action pH value of 5.0, and use a 27.12MHz radio frequency processor for auxiliary treatme...

Embodiment 3

[0065] A method for extracting honeysuckle with a high polysaccharide preservation rate and an ultra-low temperature ultrafine pulverizer, comprising the following steps:

[0066] S1. Raw material selection: select fresh honeysuckle, clean and cut;

[0067] S2. Vacuum drying of raw materials: vacuum freeze-drying the raw materials after cleaning and cutting in step S1;

[0068] S3, ultra-low temperature ultra-fine grinding: the raw material after vacuum drying in step S2 is subjected to ultra-low temperature ultra-fine grinding for 3 times, after each grinding process, powder samples are taken for particle size measurement, and the impact of grinding times on the quality of ultra-fine powder and soluble fiber is analyzed , to produce superfine powder;

[0069] S4, radio frequency assisted extraction: mix the superfine powder prepared in step S3 with the acidic electrolyzed water with an action pH value of 5.2, and use a 27.12MHz radio frequency processor for auxiliary treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com