Iron-based amorphous magnetically soft alloy with high saturation flux density and preparation method thereof

A magnetic induction intensity, iron-based amorphous technology, applied in inductor/transformer/magnet manufacturing, magnetic materials, manufacturing tools, etc., can solve the difficulty of improving alloy smelting and strip preparation, and cannot guarantee the amorphous structure of quenched strips. The problem of poor amorphous formation ability of alloys can achieve the effects of large-scale industrialization, less impurities, and lower production energy consumption and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

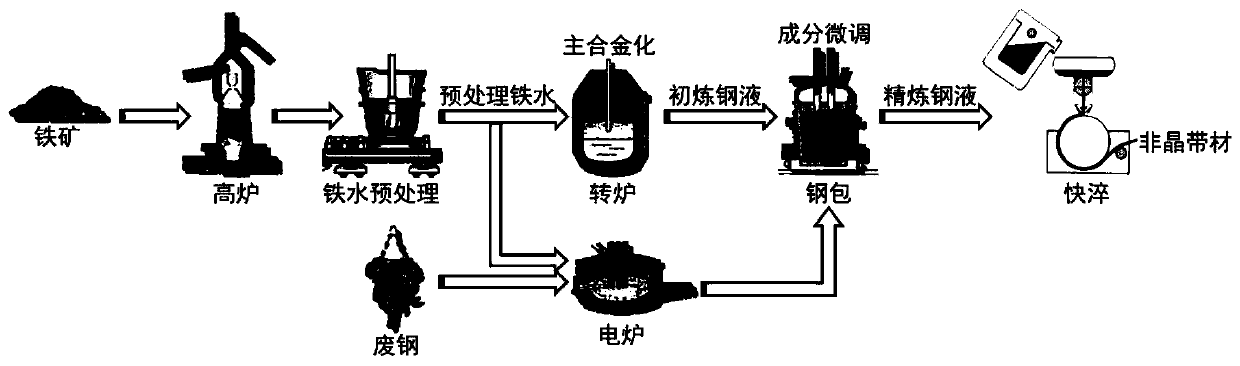

[0033] The preparation process of iron-based amorphous alloy strip is as follows: figure 1 shown. Iron ore is smelted in a blast furnace to obtain molten iron. The molten iron is desulfurized by a pretreatment process, decarburized and dephosphorized in a converter, and deoxidized and added with ferrosilicon, ferroboron, ferrophosphorus and recarburizers during the tapping process. The molten iron is alloyed by high-temperature physical heat to obtain the primary molten steel, or the scrap steel and molten iron are smelted in an electric furnace to obtain the primary molten steel. Using the high temperature physical heat of molten iron for alloying can reduce energy consumption. The primary molten steel is further refined outside the furnace to perform degassing, desulfurization, decarburization, removal of inclusions, etc., and fine-tuning the alloy composition to obtain the required refined molten steel. Then, the amorphous alloy strip is prepared by using the single-rolle...

Embodiment 1

[0037] Preparation of Alloy Fe Based on Refined Steel Melt 82.35 Si 3.7 B 10.2 P 2.8 C 0.95 (at.%), the method is as follows:

[0038] (1) Preparation of primary molten steel:

[0039] (a) Pretreatment and desulfurization of blast furnace molten iron, followed by decarburization and dephosphorization in a converter;

[0040] (b) During the tapping process, deoxidize and add ferrosilicon, ferroboron, ferrophosphorus and recarburizer, and carry out main alloying to obtain primary molten steel; the percentage composition of primary molten steel: Si 2.0%, B 2.0 %, P 1.56%, C 0.21%, Mn 0.010%, S0.006%, Ti 0.003%, Al 0.003%;

[0041] (2) Pass the initial molten steel through the ladle refining furnace (LF) to further deoxidize, desulfurize, remove inclusions, and purify the molten steel to obtain an alloy with high alloy purity; then use the vacuum degassing method (RH / VD) in the Decarburization and degassing under vacuum conditions, and the composition of the molten steel ca...

Embodiment 2

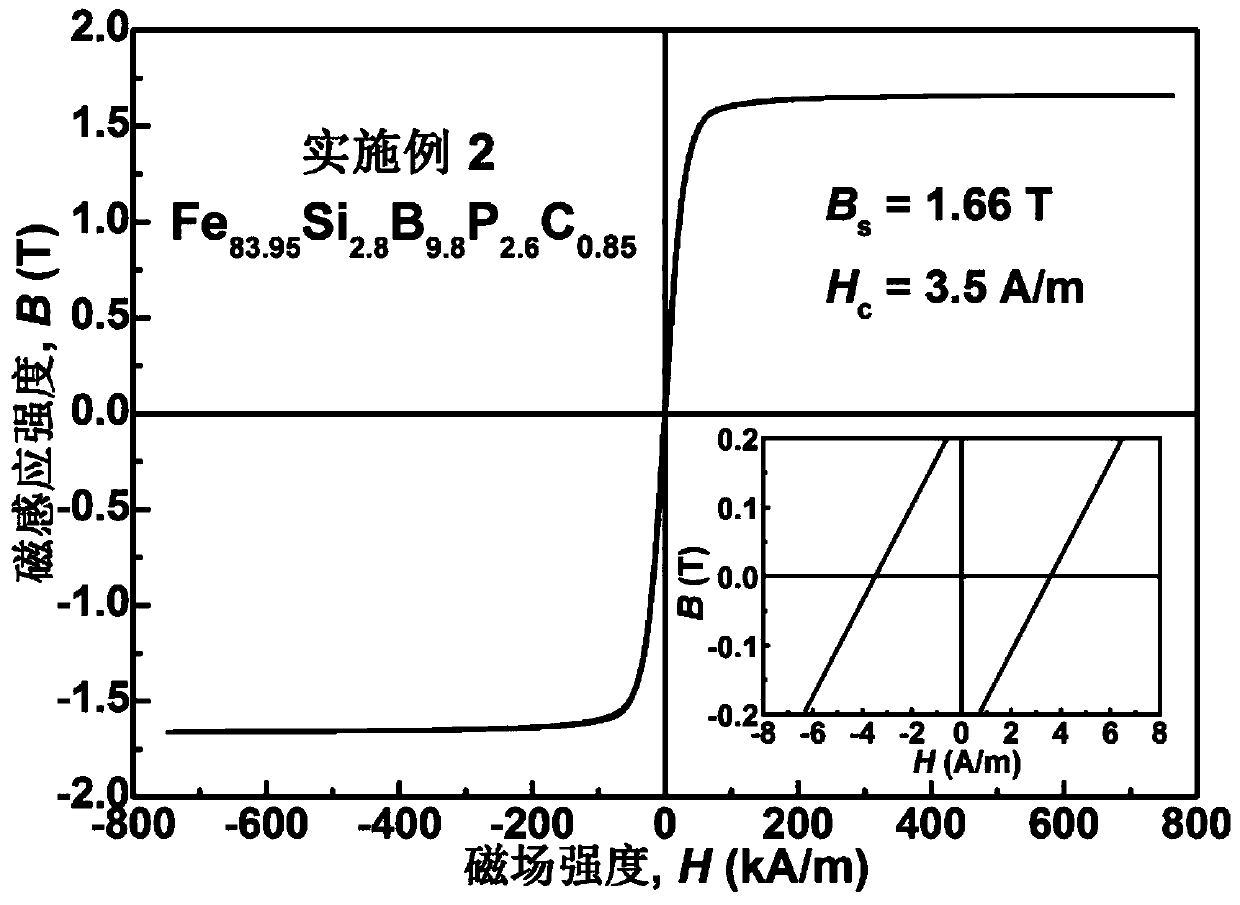

[0045] Preparation of Alloy Fe Based on Refined Steel Melt 83.95 Si 2.8 B 9.8 P 2.6 C 0.85 (at.%), the method is as follows:

[0046] (1) Preparation of primary molten steel:

[0047] (a) Pretreatment and desulfurization of blast furnace molten iron, followed by decarburization and dephosphorization in a converter;

[0048] (b) During the tapping process, deoxidize and add ferrosilicon, ferroboron, ferrophosphorus and recarburizer, and carry out main alloying to obtain primary molten steel; the percentage composition of primary molten steel: Si 1.45%, B 2.0 %, P 1.55%, C 0.18%, Mn 0.010%, S0.006%, Ti 0.003%, Al 0.003%;

[0049] (2) Pass the initial molten steel through the ladle refining furnace (LF) to further deoxidize, desulfurize, remove inclusions, and purify the molten steel to obtain an alloy with high alloy purity; then use the vacuum degassing method (RH / VD) in the Decarburization and degassing under vacuum conditions, and the composition of the molten steel ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com