Combined three-dimensional curing kiln concrete member production line and using method thereof

A technology for curing kiln and concrete, which is applied to chemical instruments and methods, conveyor objects, clay preparation devices, etc. The effect of less maintenance difficulty, lower requirements for lifting equipment, and increased effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

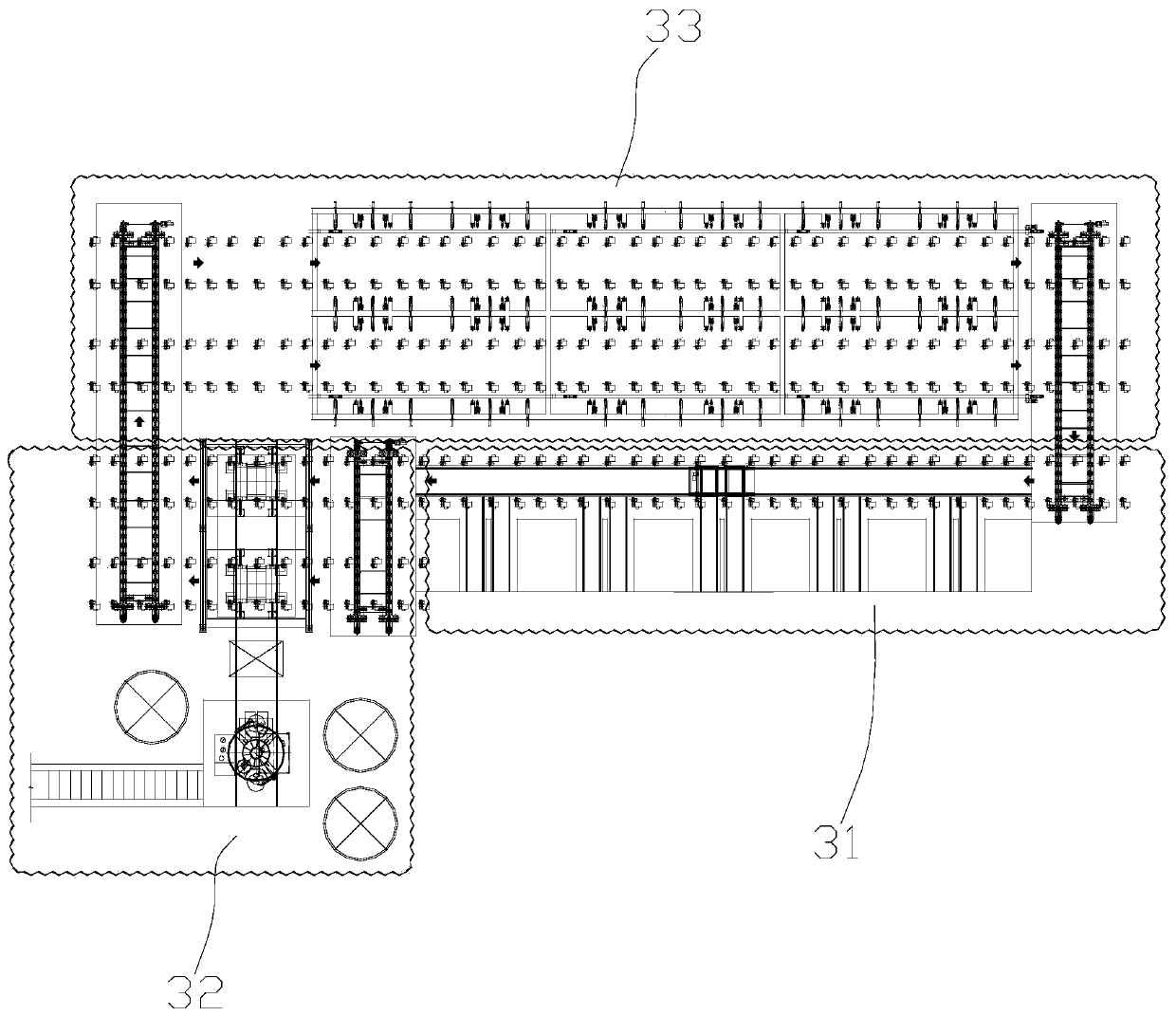

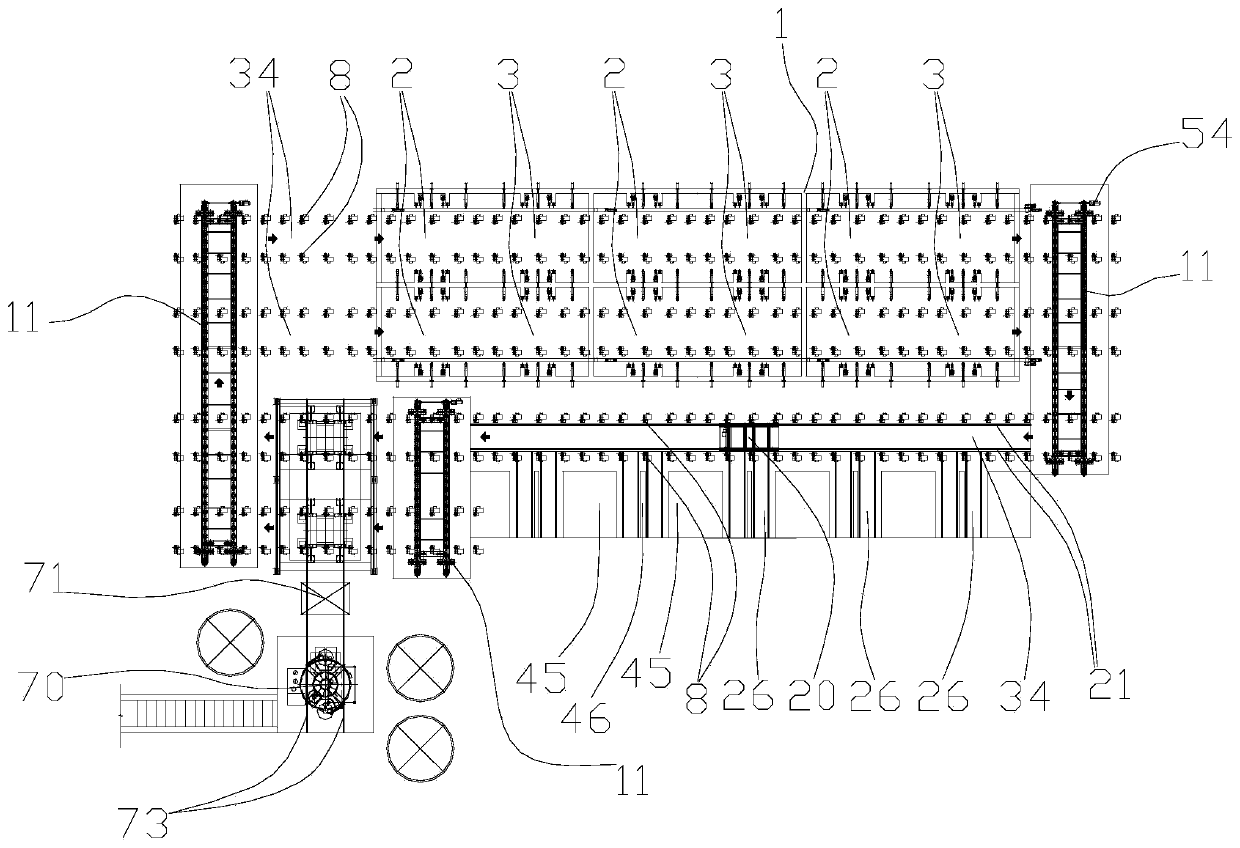

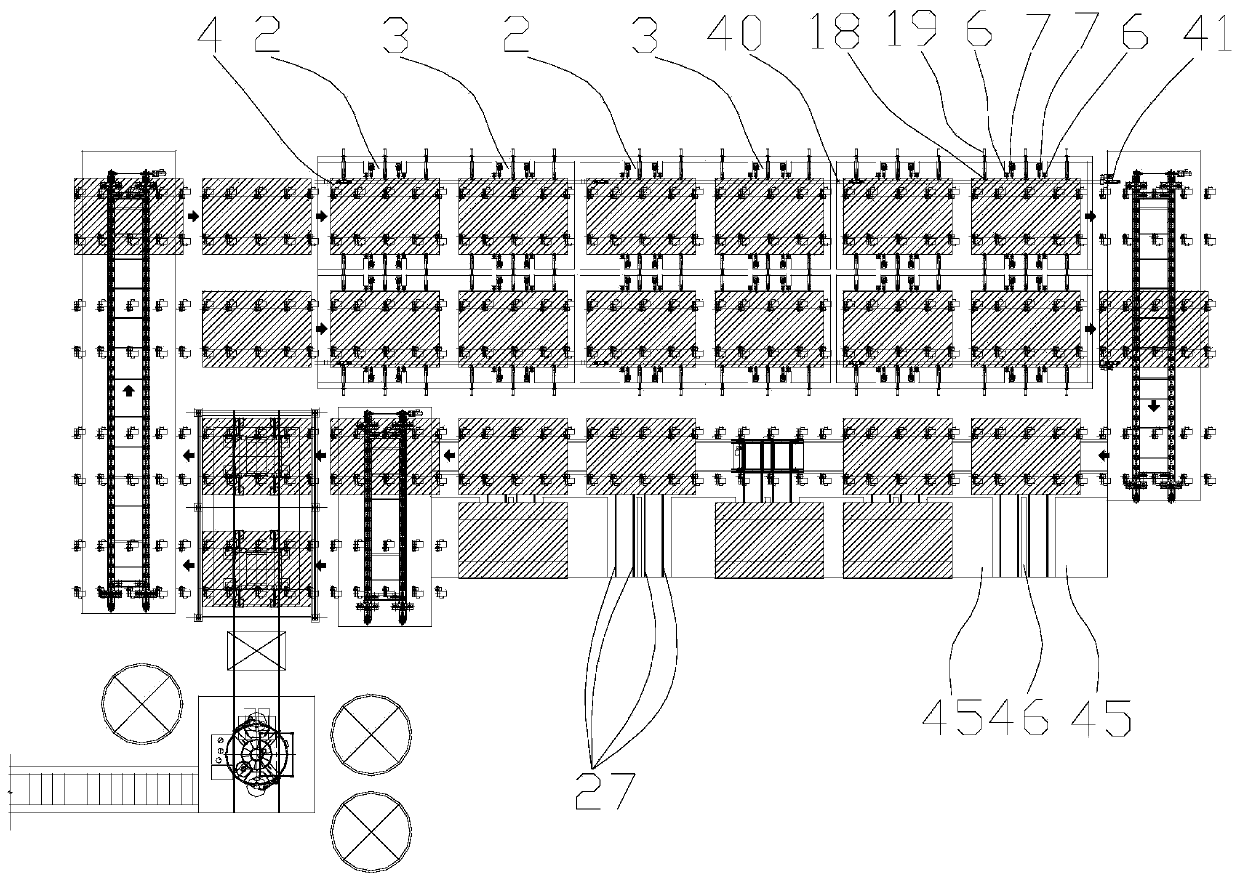

[0022] Example: see figure 1, a combined three-dimensional curing kiln concrete prefabricated component production line provided in this embodiment, which includes an empty mold operation operation area 31 and a pouring operation area set according to the operation and circulation sequence of the concrete prefabricated component mold (hereinafter referred to as the mold) 4 in the production process 32 and the maintenance operation area 33, when the production line system drives the mold 4 to flow through the empty mold operation area 31, the mold 4 is correspondingly dismantled, demoulded, cleaned, reassembled, and painted with a release agent , installation of steel cage, installation of embedded parts and inspection before pouring, etc., when the production line system drives the mold 4 to flow through the pouring operation area 32, the mold 4 performs corresponding concrete pouring operations, and the production line system When the mold 4 is driven to flow through the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com