Odorless flame-retardant vehicle wire harness cable material composition

A cable material and composition technology, which is applied in the field of odorless flame retardant cable material composition for automobile wiring harness, can solve the problems of harmful odor, environmental problems, unpleasant smell of automobile wiring harness, etc., and achieves good flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

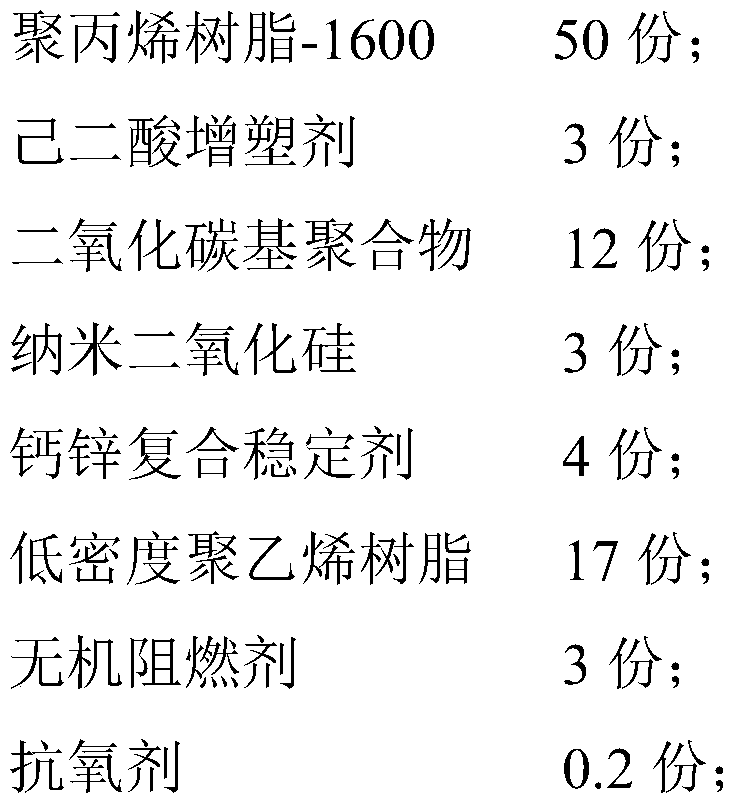

[0023] The odorless flame-retardant cable material composition for automobile wiring harnesses of this embodiment uses polypropylene resin (polymerization degree of 1600) as the main component, and is also added with adipic acid plasticizer, carbon dioxide-based polymer, nano silica, and calcium-zinc composite The stabilizer, low-density polyethylene resin, stepless flame retardant and antioxidant, in parts by weight are:

[0024]

[0025] Nano silica is active gas phase nano silica, its density is 0.1-0.2g / cm 3 .

[0026] In this embodiment, the preparation process of the odorless flame-retardant cable material composition for automobile wiring harness is as follows: 50 parts of polypropylene resin-1600, 3 parts of nano silica, 4 parts of calcium-zinc composite stabilizer, and 17 parts of low-density polymer Vinyl resin, 3 parts of inorganic flame retardant and 0.2 parts of antioxidant are mixed at 150±10℃ and stirred at low speed, then the temperature is raised to 180℃, and 3 par...

Embodiment 2

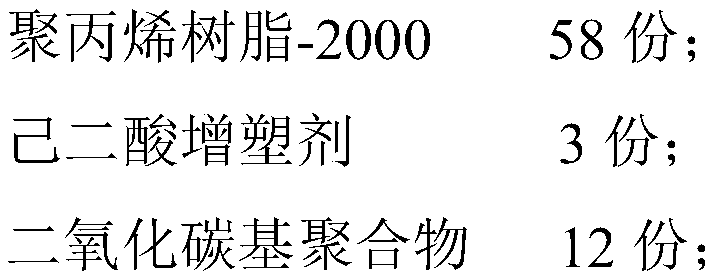

[0029] The odorless flame-retardant cable material composition for automobile wiring harnesses of this embodiment uses polypropylene resin (polymerization degree of 1600) as the main component, and is also added with adipic acid plasticizer, carbon dioxide-based polymer, nano silica, and calcium-zinc composite The stabilizer, low-density polyethylene resin, stepless flame retardant and antioxidant, in parts by weight are:

[0030]

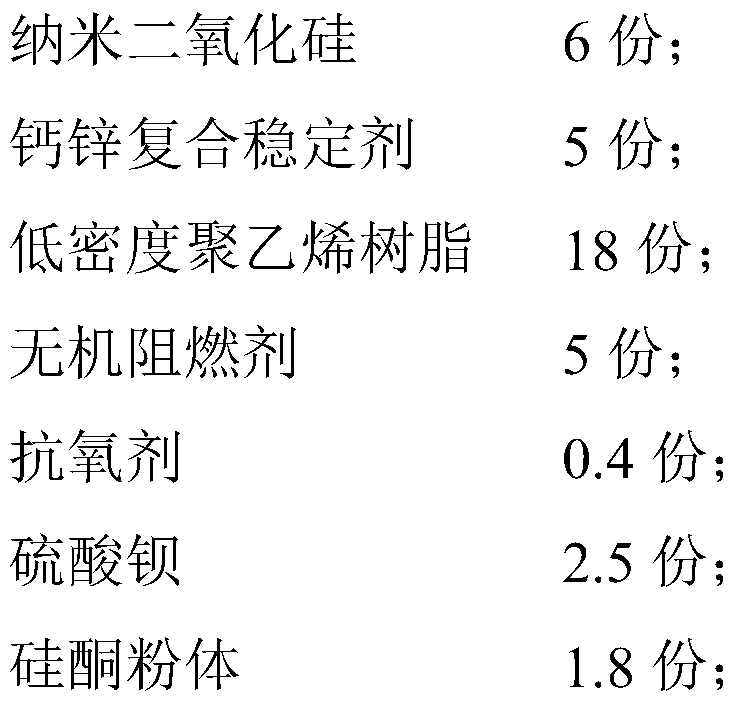

[0031]

[0032] Nano silica is active gas phase nano silica, its density is 0.1-0.2g / cm 3 .

[0033] In this embodiment, the preparation process of the odorless flame-retardant cable material composition for automobile wiring harness is as follows: combine 58 parts of polypropylene resin-2000 with 6 parts of nano silica, 5 parts of calcium-zinc composite stabilizer, and 18 parts of low-density polymer Vinyl resin, 5 parts of inorganic flame retardant, 0.4 parts of antioxidant, 2.5 parts of barium sulfate and 1.7 parts of silicone powder are mixed at 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com