An odorless flame retardant rubber v-belt

A technology of flame retardant rubber and flame retardant, which is applied in the field of transmission belts to achieve the effects of reducing usage, improving compatibility and improving flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

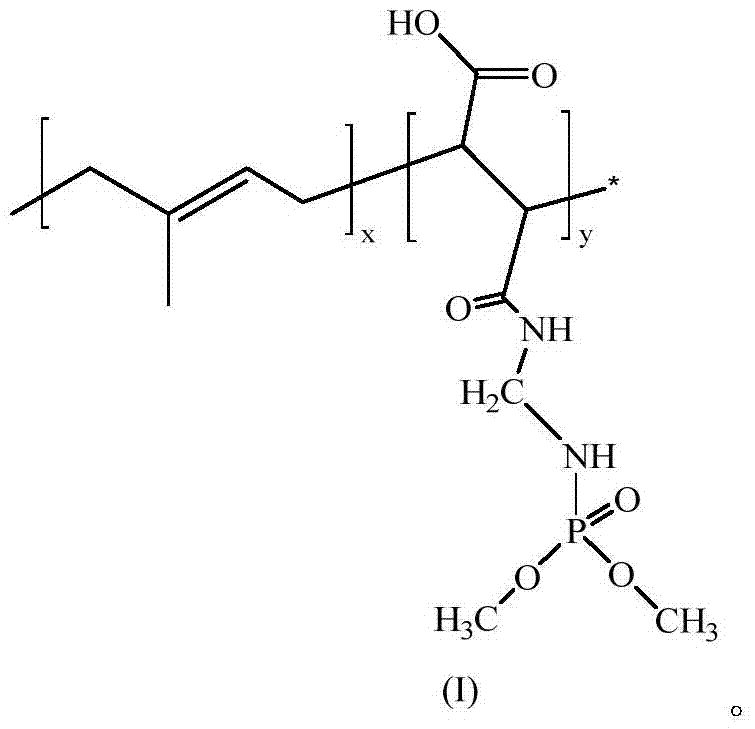

[0025] A kind of odorless flame-retardant rubber V-belt, which is composed of four parts: a cloth covering layer, a stretching layer, a strength layer and a compression layer. 0.4g part of stearic acid, 2g antioxidant, 5g zinc oxide, 4g magnesium oxide and 2g softener, the LOI of the primer material is 26.7%, and the flame retardant is the copolymer shown in formula (I) :

[0026]

[0027] In this embodiment, the preparation method of flame retardant is:

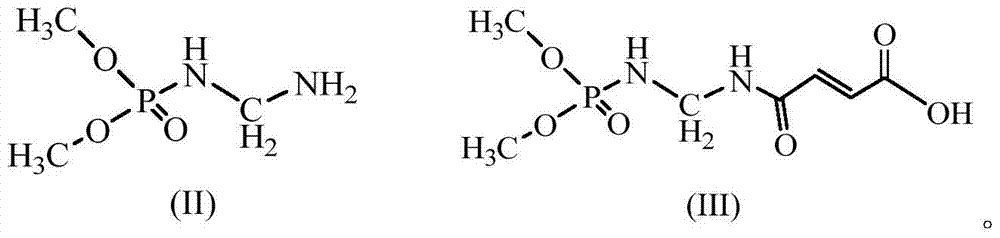

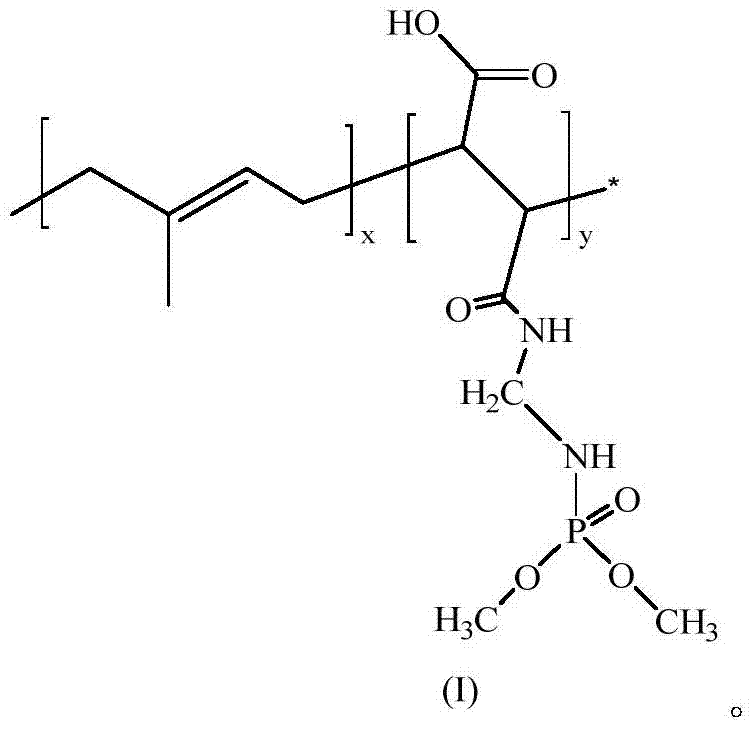

[0028] (1) Add 19.6g ethanol, 14g (0.1mol) dimethyl-2-amino-methylphosphoramidate and 9.8g (0.1mol) maleic anhydride to a 250mL three-necked flask equipped with a reflux condenser and a thermometer , stirred and heated to 40 ° C for 3 hours to prepare a mixed solution containing an intumescent flame retardant;

[0029] (2) 0.02g initiator potassium persulfate is dissolved in 50mL distilled water, stand-by;

[0030] (3) 30g of ethanol, the mixed solution of 20g of step (1) and 10g of isoprene are added to the reaction v...

Embodiment 2

[0032] A kind of odorless flame-retardant rubber V-belt, which is composed of four parts: a cloth covering layer, a stretching layer, a strength layer and a compression layer. 0.5g portion of stearic acid, 3g anti-aging agent, 7g zinc oxide, 5g magnesium oxide and 3g softener, the LOI of the primer material is 28.2%, and the flame retardant is the same as the flame retardant in Example 1.

[0033] In this embodiment, the preparation method of flame retardant is:

[0034] (1) Add 32.4g ethanol, 14g (0.1mol) dimethyl-2-amino-methylphosphoramidate and 10.8g (0.11mol) maleic anhydride to a 250mL three-necked flask equipped with a reflux condenser and a thermometer , stirred and heated to 60 ° C for 5 hours to prepare a mixed solution containing an intumescent flame retardant;

[0035] (2) 0.04g initiator potassium persulfate is dissolved in 50mL distilled water, stand-by;

[0036] (3) 40g of ethanol, the mixed solution of 30g of step (1) gained and 10g of isoprene are added in t...

Embodiment 3

[0038] An odorless flame-retardant rubber V-belt, which is composed of four parts: a cloth covering layer, a stretching layer, a strength layer and a compression layer. 0.6g part of stearic acid, 4g anti-aging agent, 8g zinc oxide, 6g magnesium oxide and 5g softener, the LOI of the primer material is 27.8%, and the flame retardant is the same as the flame retardant in Example 1.

[0039] In this embodiment, the preparation method of flame retardant is:

[0040] (1) Add 47g ethanol, 14g (0.1mol) dimethyl-2-amino-methylphosphoramidate and 11.8g (0.12mol) maleic anhydride in a 250mL there-necked flask equipped with a reflux condenser and a thermometer, Stir and heat up to 72°C for 10 hours to prepare a mixed solution containing an intumescent flame retardant;

[0041] (2) 0.06g initiator potassium persulfate is dissolved in 50mL distilled water, stand-by;

[0042] (3) 50g of ethanol, the mixed solution of 40g of step (1) gained and 10g of isoprene are added in the reaction vess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com