Dimensionally-stable heat-conducting polytetrafluoroethylene sheet and preparation method thereof

A polytetrafluoroethylene and polytetrafluoroethylene resin technology is applied in the field of dimensionally stable thermally conductive polytetrafluoroethylene sheets and their preparation, and can solve the problem of affecting the insulation performance of materials, low thermal conductivity, and large thermal expansion coefficient of polytetrafluoroethylene resin. problem, to achieve the effect of good product performance, simple preparation process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

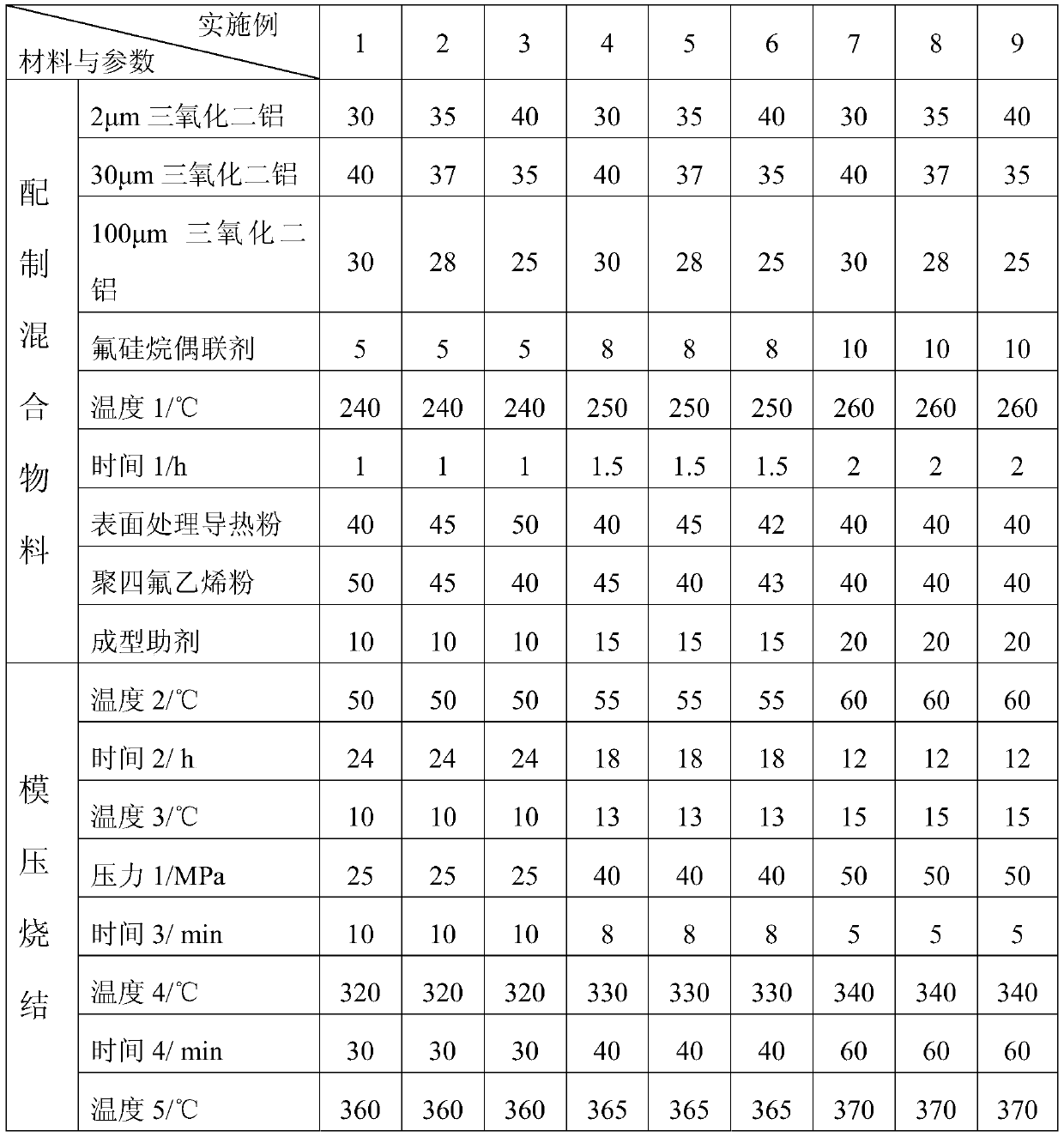

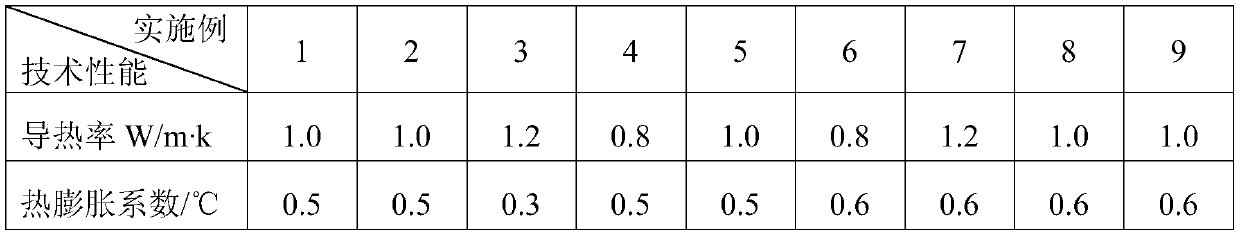

Embodiment 1~9

[0031] The basic process of preparing dimensionally stable thermally conductive PTFE sheets:

[0032] Preparation of mixed materials: Mix 100 parts by mass of spherical α-phase aluminum oxide powder with 5-10 parts by mass of fluorosilane coupling agent evenly, leave it for 24 hours, and then dry it in an oven at 240°C-260°C (temperature 1) for 1 ~ 2 hours (time 1), then pulverized into powder, made into 100 mesh surface treatment heat conduction powder material for subsequent use; The surface-treated heat-conducting powder material is uniformly mixed with 10-20wt% molding aids to form a mixed material, and stored at a temperature of 10°C-15°C for use;

[0033] Molding and sintering: place the mixture in an oven at 50°C to 60°C (temperature 2) for 12h to 24h (time 2) aging; then add the aged mixture to a temperature of 10°C to 15°C ( Temperature 3) in the mold, then increase the pressure to 25-50MPa (pressure 1) at a boosting speed of 5MPa / min, hold the pressure for 5-10min (...

Embodiment 10

[0044] A dimensionally stable heat-conducting polytetrafluoroethylene sheet is: according to the mass percentage of 40% polytetrafluoroethylene resin, 40% surface-treated heat-conducting powder material and 20% molding aids, polytetrafluoroethylene resin, surface-treated heat-conducting The mixed material prepared by mixing the powder material and the molding aid evenly is cured in an oven at a temperature of 50°C for 24h, and then molded and sintered in a film-making mold at a pressure of 25MPa and a temperature of 330°C, and then sintered at a temperature of 50°C / min. PTFE sheets with a thickness of 250 μm obtained by cooling down to room temperature at a cooling rate, that is, dimensionally stable and thermally conductive PTFE sheets;

[0045] The heat-conducting powder material for surface treatment is to mix 100 parts by mass of spherical α-phase aluminum oxide powder with 5 parts by mass of fluorosilane coupling agent evenly, place it for 24 hours, and then dry it in an o...

Embodiment 11

[0049] A dimensionally stable heat-conducting polytetrafluoroethylene sheet is: according to the mass percentage ratio of 50% polytetrafluoroethylene resin, 40% surface-treated heat-conducting powder material and 10% molding aid, polytetrafluoroethylene resin, surface-treated heat-conducting The mixed material prepared by mixing the powder material and the molding auxiliary agent evenly is cured in an oven at a temperature of 60°C for 12h, and then molded and sintered in a film-making mold at a pressure of 50MPa and a temperature of 370°C, and then sintered at a temperature of 50°C / min. PTFE sheets with a thickness of 500 μm obtained by cooling down to room temperature at a cooling rate, that is, dimensionally stable and thermally conductive PTFE sheets;

[0050] The surface-treated heat-conducting powder material is mixed uniformly with 100 parts by mass of spherical α-phase aluminum oxide powder and 10 parts by mass of fluorosilane coupling agent, left for 24 hours, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com