Fresh and wet purple-sweet-potato noodles and preparation method thereof

A purple sweet potato, fresh and wet technology, applied in the direction of food science, food ingredients as a taste improver, etc., can solve the problems of poor taste, high manufacturing cost, complicated manufacturing process, etc., and achieve beautiful color, low cost and good taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

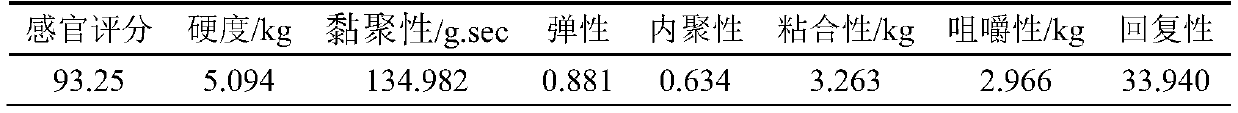

Embodiment 1

[0036] (1) Take 20kg of purple sweet potatoes and wash them with running water to remove surface dirt, remove bud eyes and diseased parts; steam them in a cooking pot until they are fully cooked, drain and cool them; remove the skin of purple sweet potatoes, and mash them into purple sweet potato puree; (2) Add 100g of sodium ascorbate and 2kg of table salt into 40kg of water to form a brine solution; add this brine solution into the purple potato mash, and after mixing evenly, homogenize. min, the pressure is 30MPa, homogenize 2 times, each time is 15min, to get the slurry; then add 100kg flour (over 80 mesh sieve) to the slurry to mix and knead the flour, make the flour become flocculent, and It can be held into a ball, and it can still become a loose flocculent dough when kneaded. The flocculent dough is kneaded into a ball and wrapped in plastic wrap; (3) then put it in a 35°C incubator to proof for 40 minutes; (4) use a noodle press machine After the proofed dough is pres...

Embodiment 2

[0043] Take 30kg of purple sweet potatoes and wash them with running water to remove surface dirt, remove bud eyes and diseased parts; steam them in a cooking pot until they are fully cooked, drain and cool them; remove the skin of purple sweet potatoes and mash them into purple sweet potato puree; (2) mix 150g of ascorbic acid Sodium and 3kg of salt are added to 50kg of water to form a saline solution, and this saline solution is added to the purple potato mash, and after mixing evenly, the homogenization temperature is 75°C, the speed of the shearing machine is 9000r / min, and the pressure is 30MPa, homogenize 2 times, each time is 15min, to obtain a slurry; then add 80kg flour (passing through an 80 mesh sieve) to the purple sweet potato slurry to mix and knead the dough, so that the flour becomes flocculent and can be held by hand. After kneading, it can still become a loose flocculent dough. The flocculent dough is kneaded into a ball and wrapped with plastic wrap; (3) then...

Embodiment 3

[0051](1) Take 40kg of purple sweet potatoes and wash them with running water to remove surface dirt, remove bud eyes and diseased parts; steam them in a cooking pot until they are fully cooked, drain and cool them; remove the skin of purple sweet potatoes, and mash them into purple sweet potato puree; (2) Add 200g of sodium ascorbate and 4kg of table salt into 50kg of water to form a brine solution; add this brine solution into the purple sweet potato mash and beat it to make a homogeneous, homogeneous temperature of 75°C, the speed of the shearing machine is 9000r / min, and the pressure is 30MPa , homogenized 2 times, each time is 15min, to obtain a slurry; then add 90kg flour (passing through an 80 mesh sieve) to the purple sweet potato slurry to mix and knead the flour, making the flour flocculent and can be held into a ball by hand , kneading can still become a loose flocculent dough, and the flocculent dough is kneaded into a ball and wrapped in plastic wrap; (3) then put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com