Prosthesis based on connection structure of porous surface structure and substrate

A technology of surface structure and porous structure, applied in prosthesis, additive manufacturing, medical science, etc., can solve problems such as damage to porous structure, high heat generated by contact, and low bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

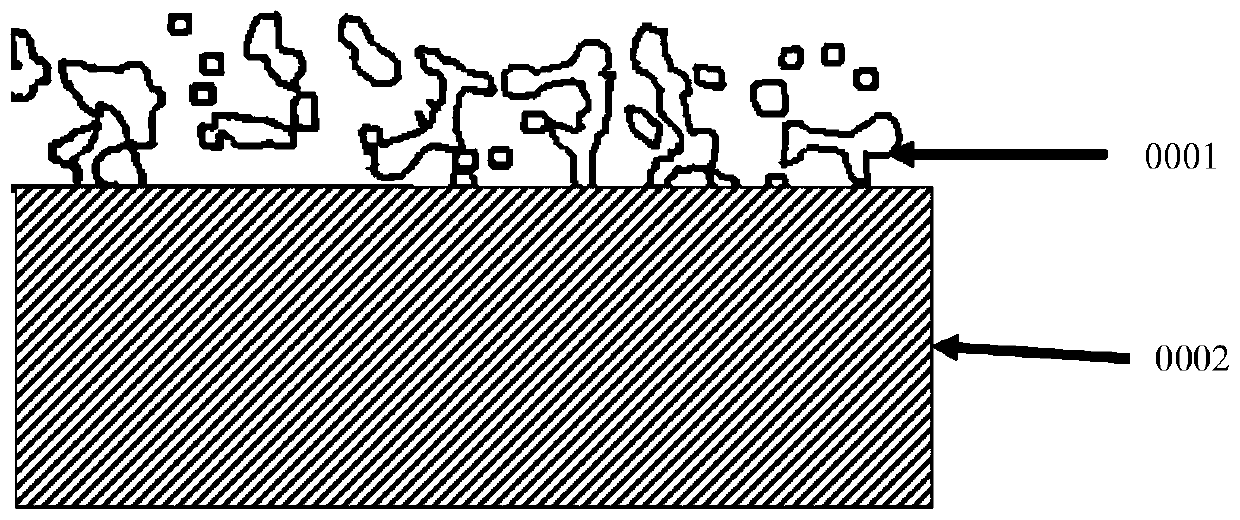

Problems solved by technology

Method used

Image

Examples

Embodiment 1

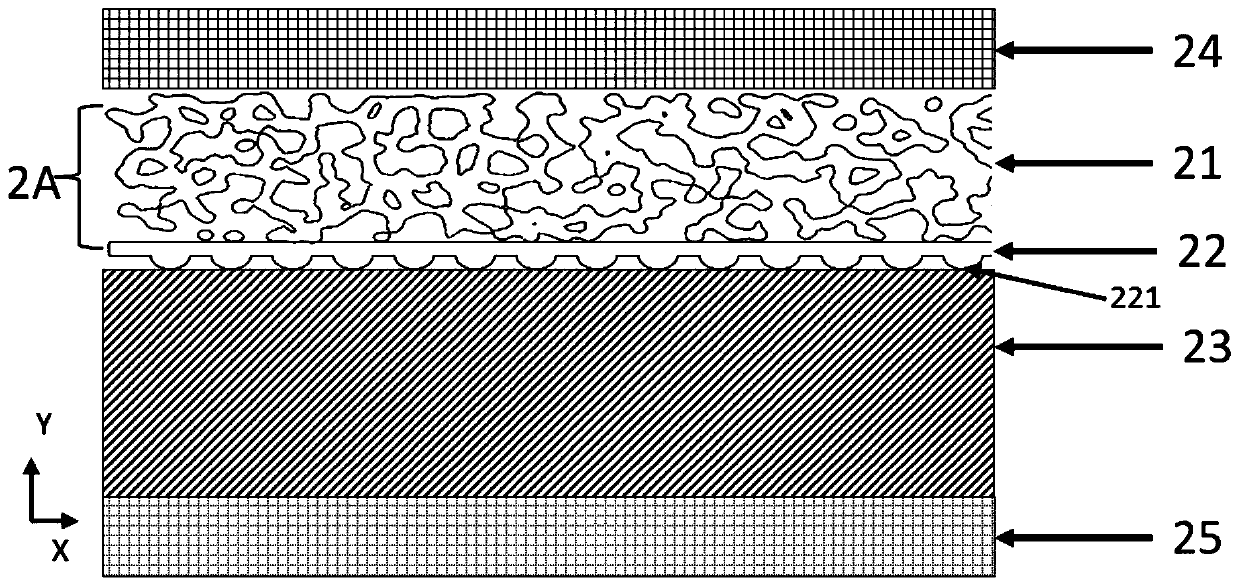

[0098] Such as figure 2 As shown, the present invention provides a connection structure, including a substrate 23 , an intermediate body 22 , and a porous surface structure 21 . Wherein, the porous structure of the porous surface structure 21 includes many struts (or beams) arranged in a staggered manner, and some multi-directional through-through, regular or irregular pores are formed between these struts (or beams). The intermediate body 22 is located between the porous surface structure 21 and the substrate 23 . Optionally, the intermediate body 22 is a non-porous bottom plate, that is, a solid bottom plate. Both the porous surface structure 21 and the intermediate body 22 are made of conductive materials (such as metal materials). The porous surface structure 21 and the intermediate body 22 are integrally formed, for example, by 3D printing additive manufacturing process, or vapor deposition process.

[0099] Exemplarily, the base 23 is solid, which is beneficial to th...

Embodiment 2

[0110] For the first embodiment above, the porous surface structure 21 is a structure with a certain porosity, the intermediate body 22 is located between the porous surface structure 21 and the substrate 23 , and the intermediate body 22 is a non-porous bottom plate 22 . In fact, the intermediate body 22 can be the solid plate described in the first embodiment, or the porous structure with low porosity described in the second embodiment.

[0111] Therefore, the main difference from Embodiment 1 is that the connection structure of Embodiment 2 includes a first porous structure 41 in a high-porosity region, a second porous structure 42 in a low-porosity region (as an intermediate) and a substrate 43 ,Such as Figure 4a shown. The second porous structure 42 is located between the first porous structure 41 and the substrate 23 .

[0112] Illustratively, the porous structures of the first porous structure 41 and the second porous structure 42 both contain numerous staggered supp...

Embodiment 3

[0119] For the first embodiment above, the top of the negative electrode 25 is in close contact with the bottom of the substrate 23, and the bottom of the positive electrode 24 is in close contact with the top of the porous surface structure 21; optionally, the positive electrode 24 and the negative electrode 25 are large The positive electrode 24 covers the top of the porous surface structure 21 , and the negative electrode 25 covers the bottom of the substrate 23 . Since the large-planar positive electrode 24 of Embodiment 1 is pressed on the top of the porous surface structure 21, the large-planar positive electrode 24 contacts and squeezes the surface of the porous surface structure 21, causing damage to the surface of the porous surface structure 21, for example, due to being Depression occurs due to pressure, and blackening, depression, and reduction of pore space are caused by temperature rise due to contact resistance heat generation.

[0120] In order to protect the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com