Temperature-sensitive calcium phosphate bone cement and preparation method thereof

A calcium phosphate bone cement, temperature-sensitive technology, applied in the field of biomedical engineering, can solve the problems of low mechanical properties, poor degradation resistance, cytotoxicity of β-glycerophosphate disodium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

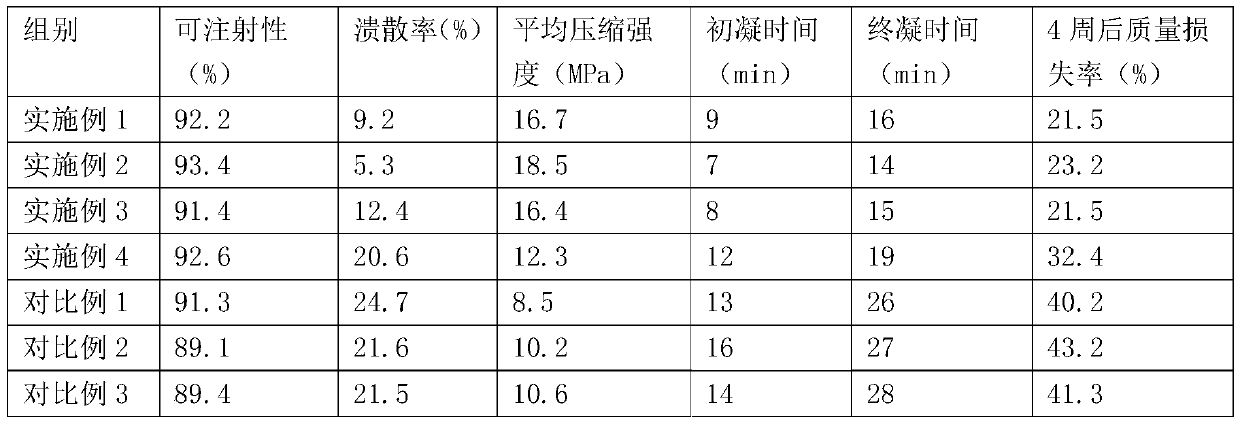

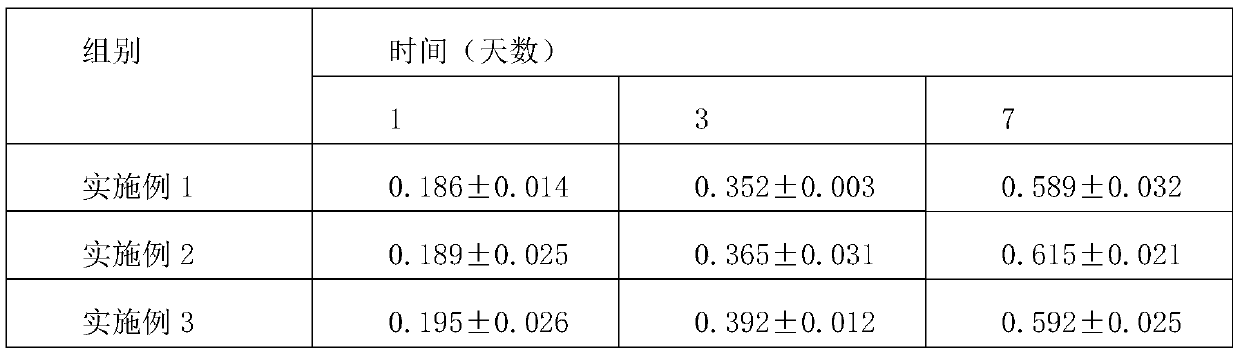

Examples

Embodiment 1

[0037] A temperature-sensitive calcium phosphate bone cement, comprising a solid phase powder and a liquid phase component, the mass ratio of the solid phase powder to the liquid phase component is: 1.5:1;

[0038] The solid phase powder is α-tricalcium phosphate;

[0039] The liquid phase components are prepared by the following method:

[0040] Configuration mass fraction is 4% gamma-glycidyl etheroxypropyl trimethoxysilane;

[0041] Configuration mass fraction is 3% chitosan acetic acid aqueous solution: dissolving chitosan in 1wt% acetic acid solution is made into mass fraction is 3% chitosan acetic acid aqueous solution, wherein chitosan is deacetylated 90% Chitosan powder with a molecular weight of 700,000;

[0042] The preparation mass fraction is the sodium glycerophosphate solution of 50%;

[0043] The preparation mass fraction is 10% bletilla striata polysaccharide solution;

[0044] Mix Bletilla striata polysaccharide solution, γ-glycidyl etheroxypropyl trimetho...

Embodiment 2

[0046] A temperature-sensitive calcium phosphate bone cement, comprising solid phase powder and liquid phase components, the mass ratio of solid phase powder and liquid phase components is: 2:1;

[0047] The solid phase powder is α-tricalcium phosphate;

[0048] The liquid phase components are prepared by the following method:

[0049] Configuration mass fraction is 6% gamma-glycidyl etheroxypropyl trimethoxysilane;

[0050]Configuration mass fraction is 5% chitosan acetic acid aqueous solution: dissolving chitosan in 1wt% acetic acid solution is made into mass fraction is 5% chitosan acetic acid aqueous solution, wherein chitosan is deacetylated 90% Chitosan powder with a molecular weight of 700,000;

[0051] The preparation mass fraction is the sodium glycerophosphate solution of 60%;

[0052] The preparation mass fraction is 20% bletilla striata polysaccharide solution;

[0053] Mix Bletilla striata polysaccharide solution, γ-glycidyl etheroxypropyl trimethoxysilane, ch...

Embodiment 3

[0055] A temperature-sensitive calcium phosphate bone cement, comprising a solid phase powder and a liquid phase component, the mass ratio of the solid phase powder to the liquid phase component is: 2.7:1;

[0056] The solid phase powder is α-tricalcium phosphate;

[0057] The liquid phase components are prepared by the following method:

[0058] Configuration mass fraction is 5% gamma-glycidyl etheroxypropyl trimethoxysilane;

[0059] Configuration mass fraction is 4% chitosan acetic acid aqueous solution: dissolving chitosan in 1wt% acetic acid solution is made into mass fraction is 4% chitosan acetic acid aqueous solution, wherein chitosan is deacetylated 90% Chitosan powder with a molecular weight of 800,000;

[0060] Preparation mass fraction is 40% sodium glycerophosphate solution;

[0061] The preparation mass fraction is 15% bletilla striata polysaccharide solution;

[0062] Mix Bletilla striata polysaccharide solution, γ-glycidyl etheroxypropyl trimethoxysilane, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com