C/Bi/Bi2MoO6 polarization material, preparation method thereof and application of material in photocatalytic degradation of dyes

A photocatalytic and dye technology, applied in the field of photocatalytic materials, can solve the problems of high cost and difficult recycling of materials, and achieve the effects of low cost, good photocatalytic degradation performance, and uniform microscopic morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] C / Bi / Bi of this embodiment 2 MoO 6 The preparation method of polarized material comprises the following steps:

[0054] (1) Preparation of EDTA-Bi precursor

[0055] Take 1.0mL concentrated nitric acid and dissolve it in 29.0mL water, then add 4.8500g Bi(NO 3 ) 3 ·5H 2 O and 2.92g EDTA, ultrasonically dissolved for 20min, and then use 14% NH 3 ·H 2 O adjusted the pH of the solution to 6.5, stirred for 2 h, collected the solid sediment after centrifugation and dried at 100 °C for 20 h to obtain the EDTA-Bi precursor.

[0056] (2) C / Bi / Bi 2 MoO 6 Preparation of composite materials

[0057] Weigh 1.6866g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 5.0mL ethylene glycol to obtain liquid A; then weighed 0.4210gNa 2 MoO 4 2H 2 O was dissolved in 5.0mL ethylene glycol to obtain liquid B;

[0058]Add 0.0530g of the EDTA-Bi precursor prepared in step (1) to liquid A, and after stirring thoroughly, drop liquid B into liquid A, stir to make it fully react, and obtain liqu...

Embodiment 2

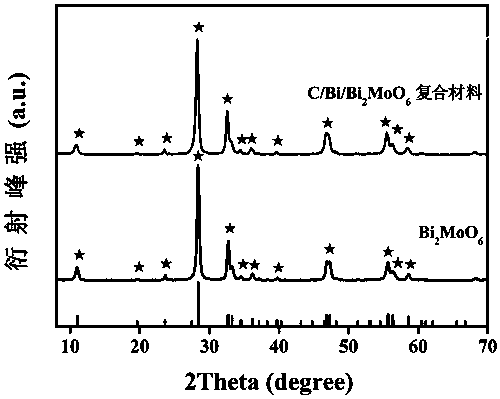

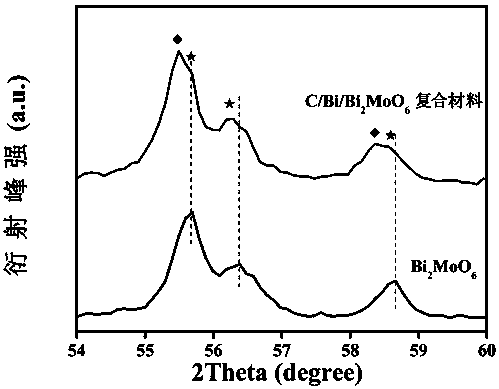

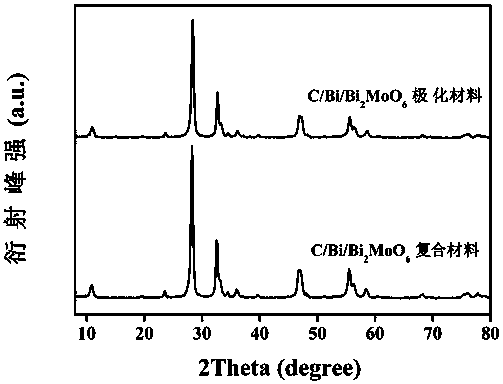

[0063] For verifying the C / Bi / Bi of embodiment 1 of the present invention 2 MoO 6 Whether the preparation of the polarized material is successful, the applicants respectively compare Bi 2 MoO 6 、C / Bi / Bi 2 MoO 6 Composites and C / Bi / Bi 2 MoO 6 The polarized material was analyzed by XRD, SEM, FT-IR and XPS. The specific experimental results are as follows.

[0064] Bi used in this example 2 MoO 6 The preparation method comprises the following steps: weighing 1.6866g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 5.0 mL of ethylene glycol to give Bi(NO 3 ) 3 solution; then weigh 0.4210g Na 2 MoO 4 2H 2 O was dissolved in 5.0 mL of ethylene glycol to give Na 2 MoO 4 solution; while stirring, Na 2 MoO 4 The solution was dropped into Bi(NO 3 ) 3 solution, then add 20.0 g of ethanol to the solution, stir well, transfer the obtained suspension to a 45.0 mL stainless steel autoclave, react at 160°C for 10 h, cool naturally to room temperature, and use the obtained solid Alte...

Embodiment 3

[0087] C / Bi / Bi of this embodiment 2 MoO 6 The application of polarized materials in the catalytic degradation of colored dye malachite green, take three 50mL malachite green solutions with a concentration of 10mg / L, and number them #1, #2 and #3 respectively, and send them to #1 and #2 respectively and #3 solution was added with 0.02g Bi 2 MoO 6 , 0.02g C / Bi / Bi 2 MoO 6 Composite material and 0.02g C / Bi / Bi 2 MoO 6 The polarized materials act as catalysts respectively, and the solution maintains the original pH. First, 30 minutes of dark light treatment was performed to achieve adsorption-desorption equilibrium, and then light was applied for 60 minutes, and the test was performed every 10 minutes. Figure 18 is the graph of photocatalytic degradation of malachite green for three different catalysts. It can be seen from the figure that pure Bi 2 MoO 6 The degradation rate was only 53.1% within 60 minutes, and the C / Bi / Bi after introducing C and Bi 2 MoO 6 The degradat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com