Method for forming thin-walled volute shell with spiral structure on basis of counter-gravity casting

A kind of anti-gravity casting and spiral technology, applied in the field of sand casting, can solve the problems of inapplicable thin-walled structure forming, difficult to achieve defect-free casting forming, reduction of molten metal filling speed, etc. The effect of speed, shortening development cycle, improving manufacturing efficiency and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

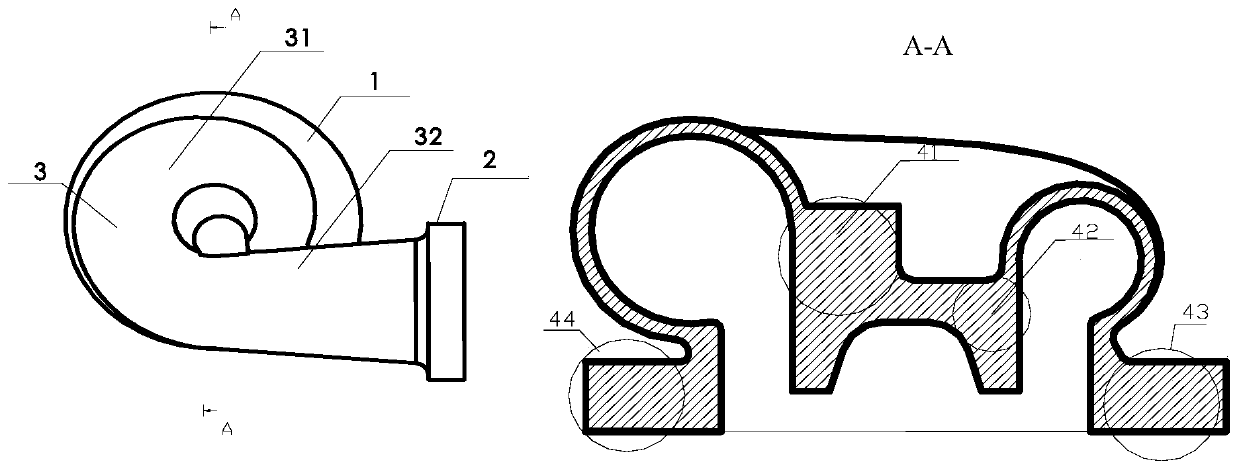

[0100] Taking the volute casing of the kerosene pre-compression pump of the liquid oxygen kerosene high-pressure supplementary combustion engine as an example, its structure is as follows: figure 1 As shown, it is mainly composed of inlet flange 1, outlet flange 2 and vortex 3. The vortex is composed of a helical vortex chamber 31 and a diffuser tube 32. Its minimum wall thickness is only 3mm, which belongs to a typical thin-walled complex volute. The structure, the material of this part is ZL104, and the chemical composition is shown in Table 1.

[0101] Table 1 Required chemical composition (wt.%)

[0102] element Si Mg mn Fe Cu Zn sn GB / T1173-95 8~10.5 0.17~0.3 0.2~0.5 ≤0.6 ≤0.3 ≤0.3 ≤0.01

[0103] (1) Casting process design.

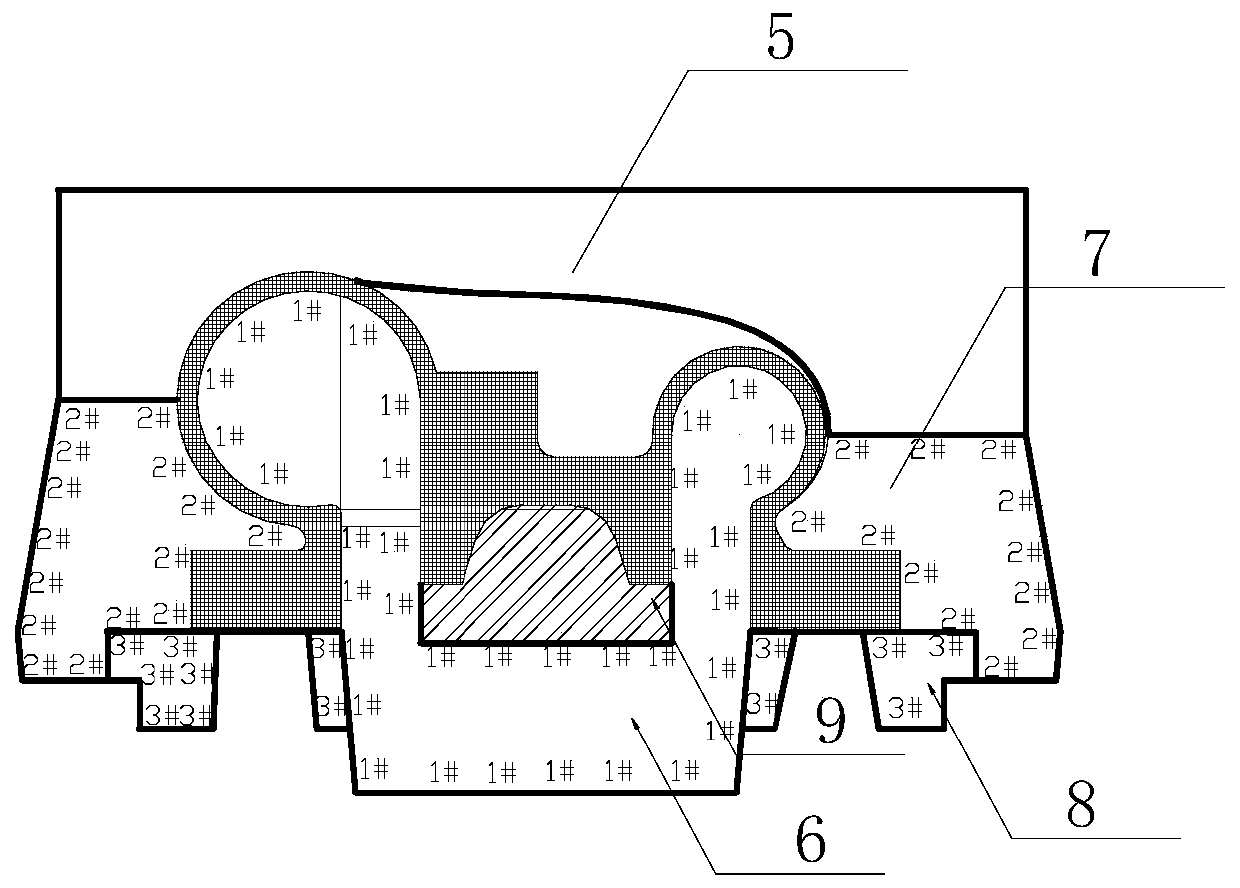

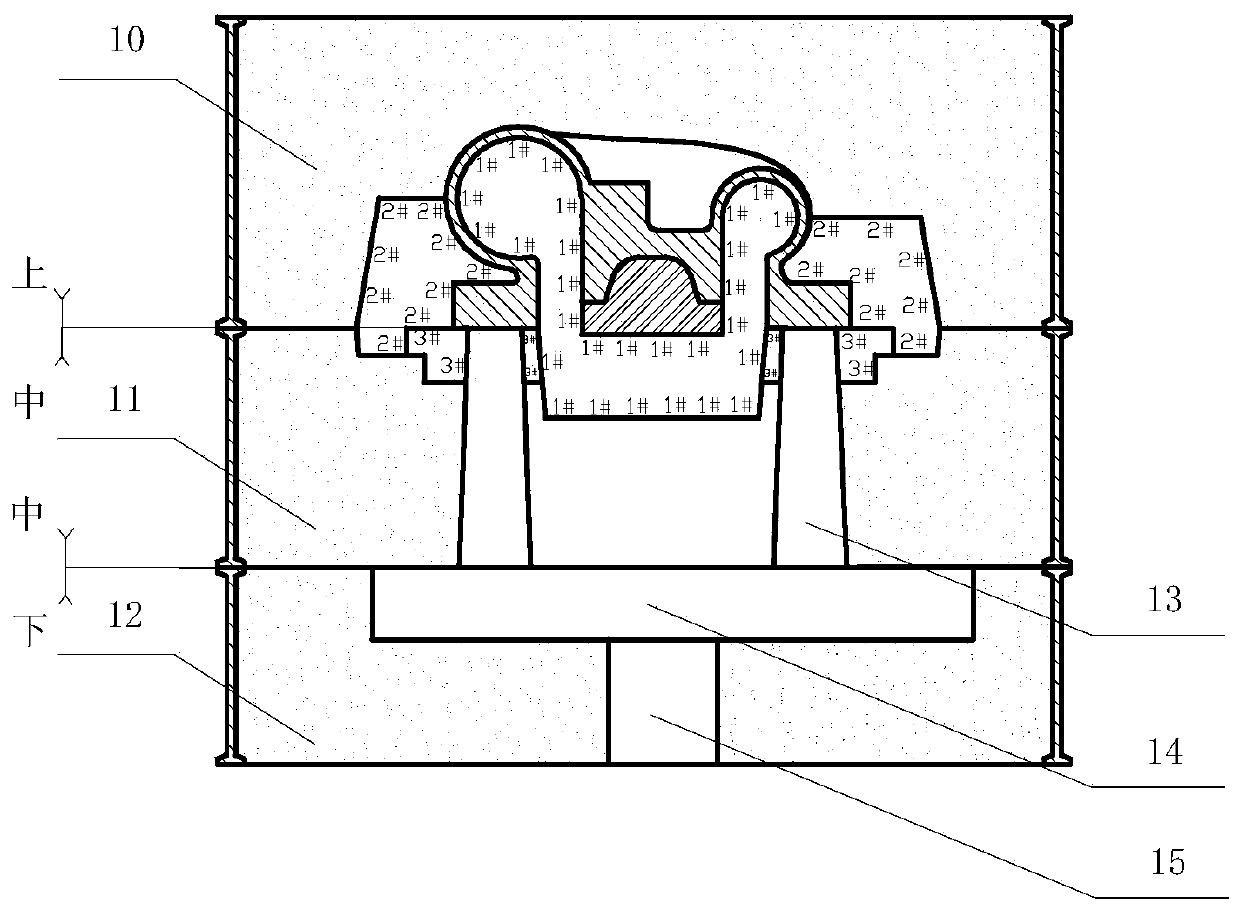

[0104] According to the design blueprint, use the 3D modeling software Pro / engineer or UG to construct the 3D model of the product and carry out the casting process design. The process includes: 1. By subdivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com