Metal-plastic composite plate production line and metal-plastic composite plate production method

A composite board and production line technology, which is applied to flat products, household appliances, and other household appliances, can solve the problems of high energy consumption and low degree of mechanization, and achieve the effect of high degree of mechanization and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

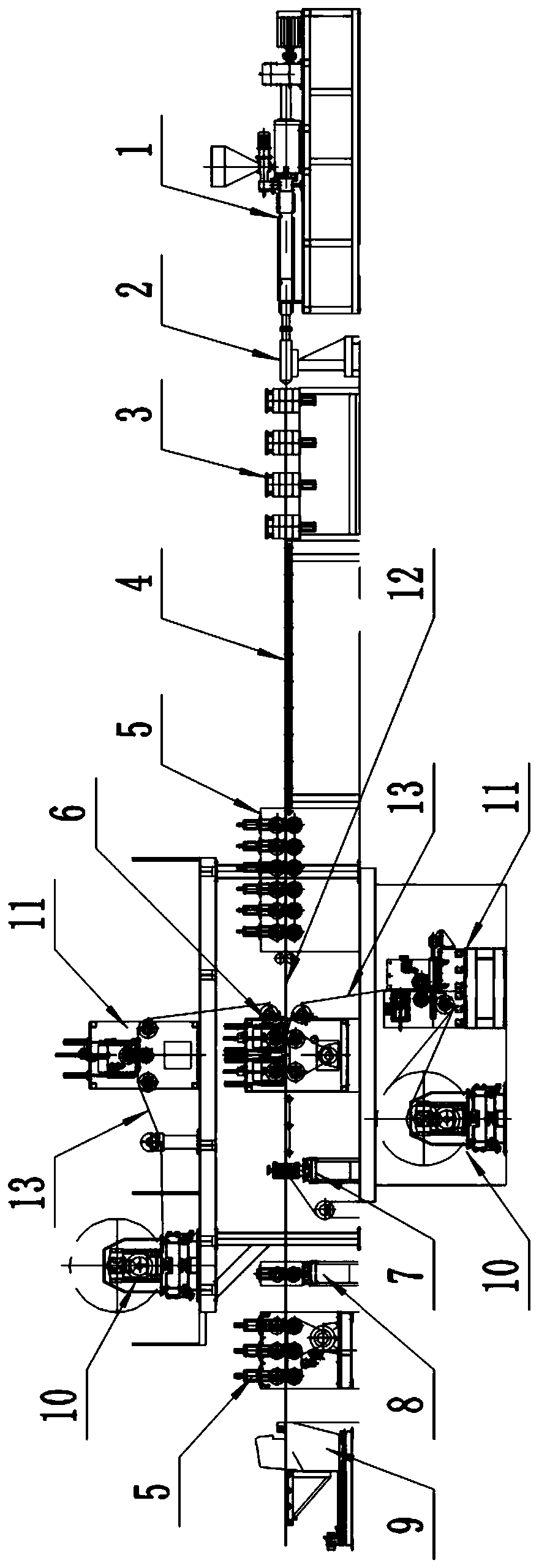

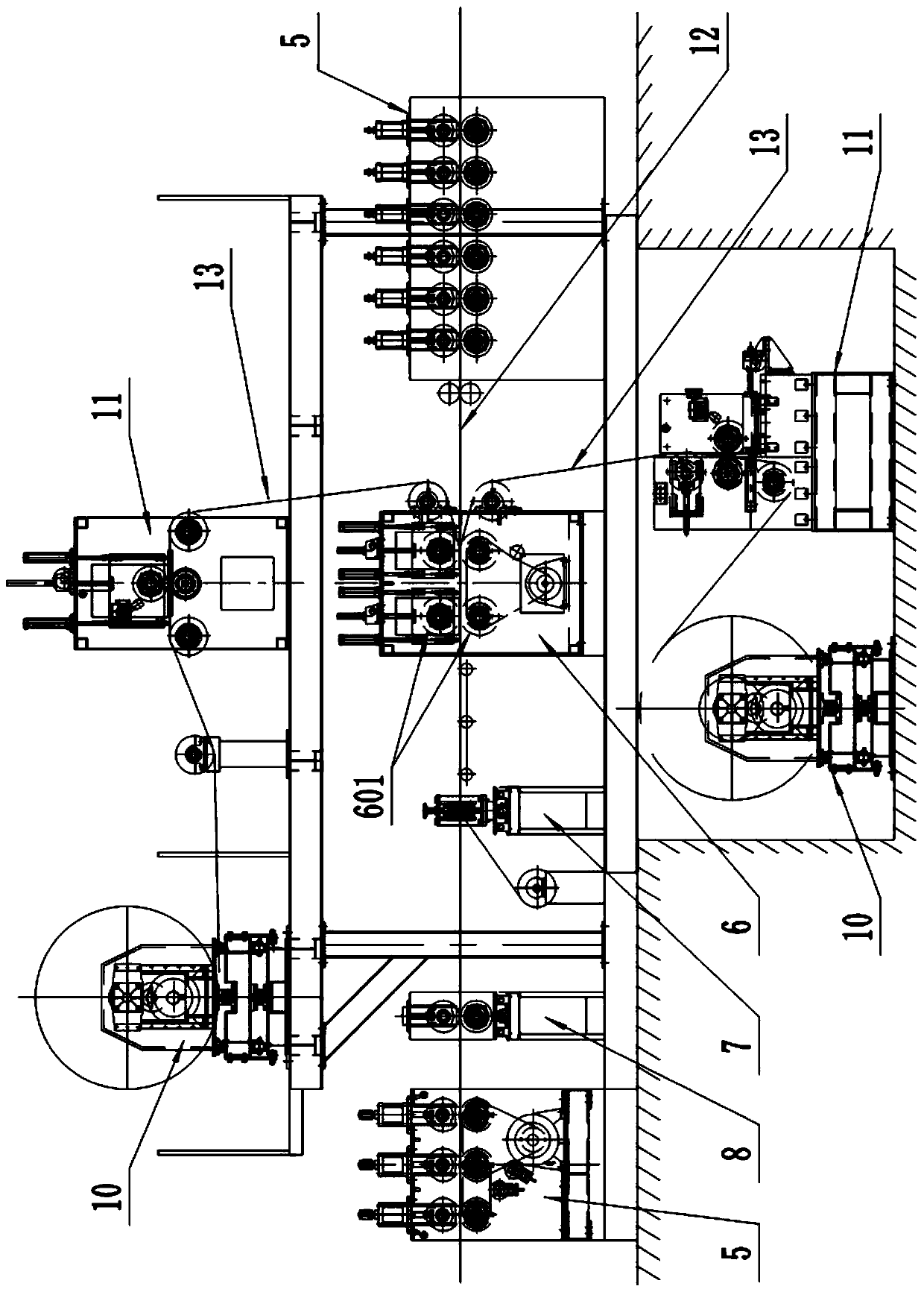

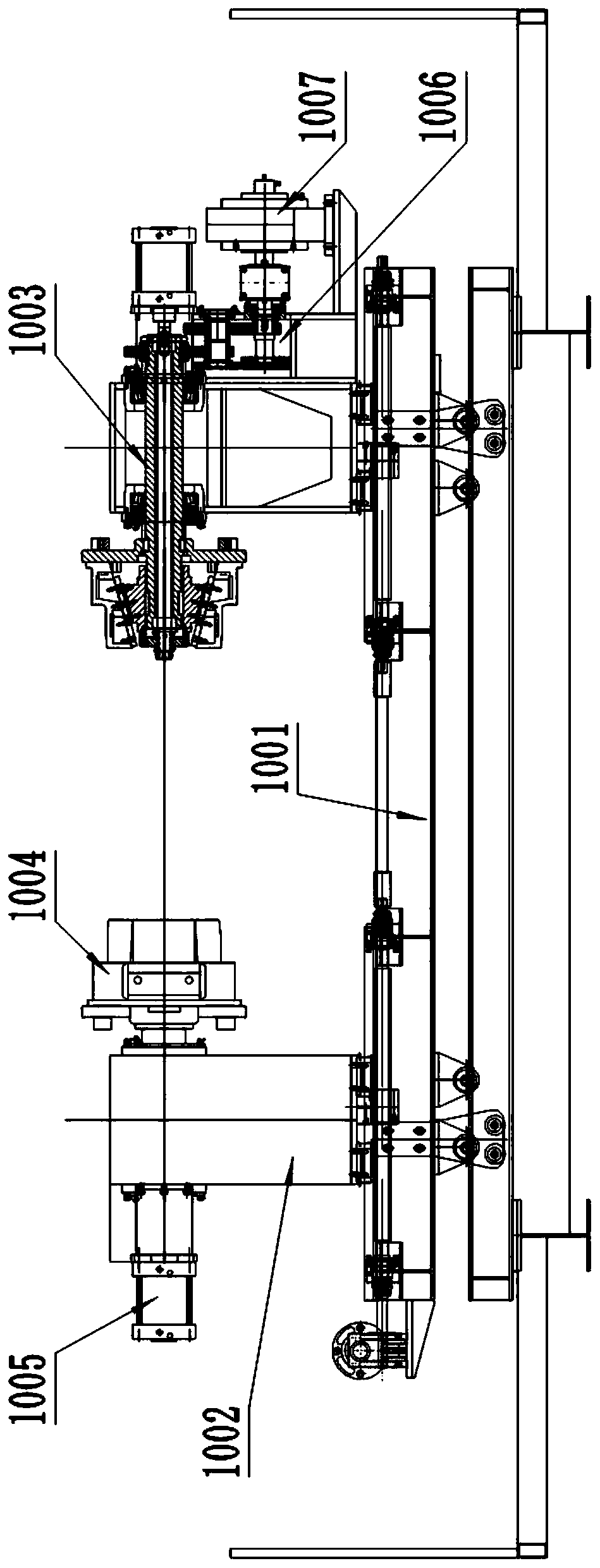

[0040] like Figure 1-5 As shown, embodiment 1 provides a kind of production line of gold-plastic composite board, including the existing mixing machine, feeding machine, extruder 1, machine head 2, forming machine 3, cooling roller 4 connected in sequence , tractor 5, edge cutting device, composite machine 6, fixed-width cutting device 7, double-sided laminating machine 8, tractor 5, cross-cutting machine 9, stacking manipulator and stacking platform, including a unique retractable Coiler 10 and glue coating machine 11, retracting and unwinding machine 10, glue coating machine 11 and composite machine 6 are connected in sequence, and retracting and unwinding machine 10 and glue coating machine 11 are equipped with two sets, and two retractable and unwinding machines The winding machine 10 is respectively arranged on the upper side and the lower side of the compound machine 6, and two glue coating machines 11 are respectively arranged on the upper side and the lower side of th...

Embodiment 2

[0055] like Image 6 As shown, embodiment 2 provides a kind of production method of gold-plastic composite board, and it comprises the following steps;

[0056] Step S1, mixing materials; adding the PVC mixed raw materials to the mixer, mixing the mixed raw materials in the mixer, setting the temperature in the mixer to 100-110°C, stirring for 10-15 minutes, and then cooling the mixed raw materials to room temperature;

[0057]Step S2, feeding; feeding the mixed raw materials in the mixer into the extruder through the feeder;

[0058] Step S3, extrusion; the mixed raw materials are heated to 180-200°C in the extruder, and then the heated mixed raw materials are extruded from the discharge port of the extruder and enter the machine head, and the mixed raw materials are in the machine head Form a plate, the thickness of the plate is 3-20mm, and the outlet of the machine head is extruded;

[0059] Step S4, cooling and molding; the sheet is extruded from the machine head and en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com