Central-driven ultra-large load smart self-adaptive electric drive system

A technology of electric drive system and super large load, applied in the direction of power device, electric power device, control device, etc., can solve the problems of difficult production, limited load capacity, difficult to guarantee machining accuracy, etc., to increase the range of efficient operation, improve The effect of high load bearing capacity, stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the examples and drawings.

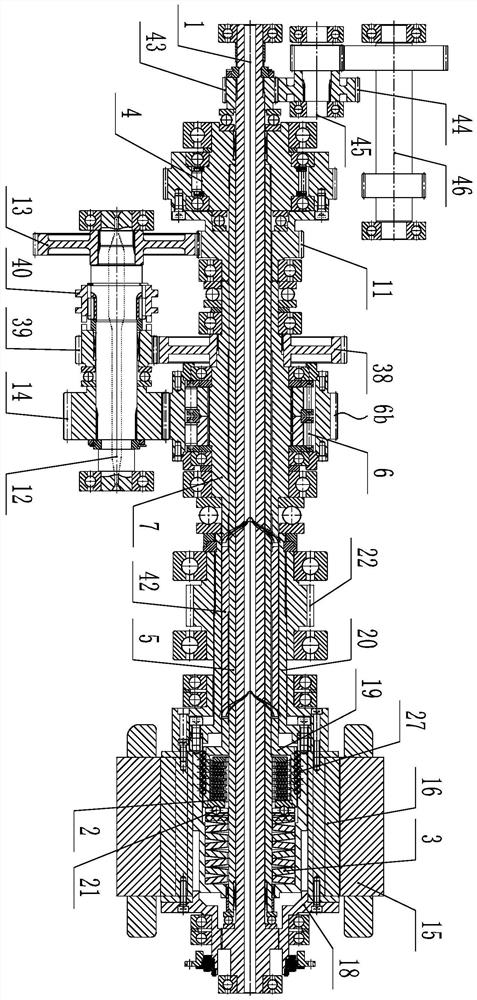

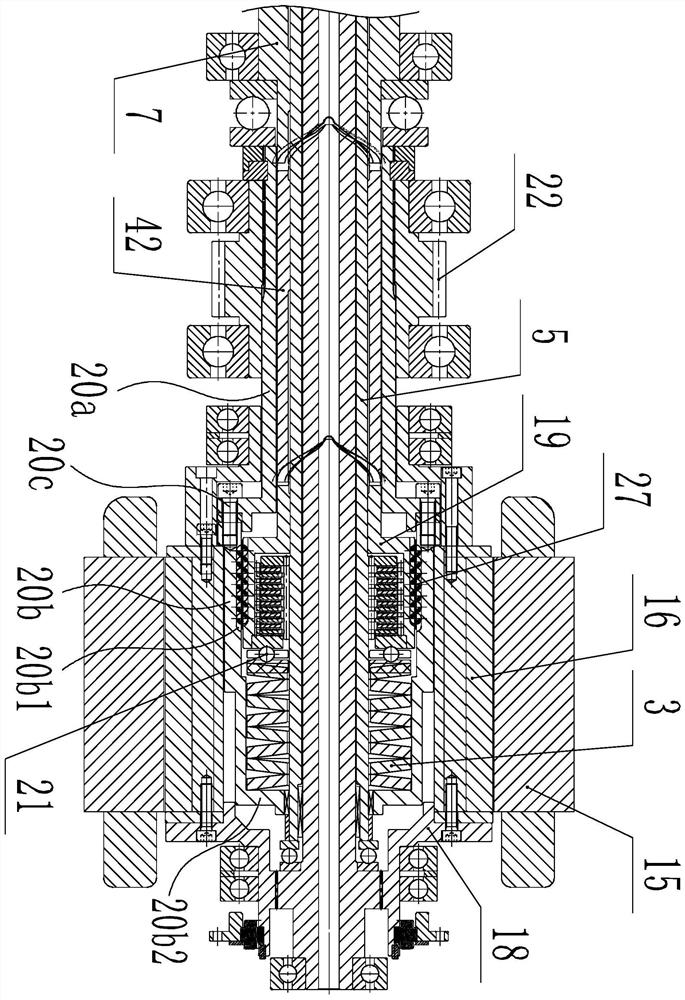

[0040] Such as Figure 1 - Figure 4 As shown in a central intelligence-driven adaptive large electric load drive system includes a motor, a high-speed gear transmission mechanism, a low gear transmission mechanism and the center output.

[0041] The motor includes a stator 15, rotor 16 and the output shaft assembly 16 by a motor driven rotor assembly comprising the motor shaft output power transmitting flange 18, a motor shaft, the first overrunning clutch and the first reduction assembly 4, the rotor 16 of the flange 18 can be transmitted through the power transmitting power to a motor shaft, the first overrunning clutch 4 is rotatably fitted over a motor shaft, the motor shaft 1 can be transmitted to a power.

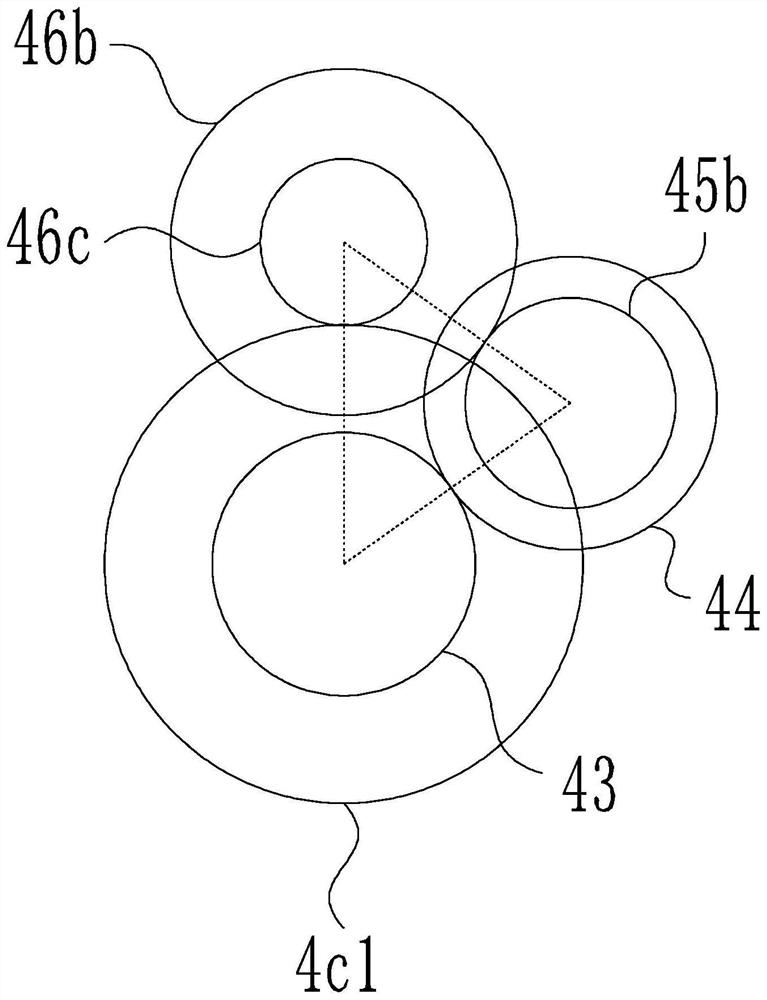

[0042] See figure 1 , figure 2 and Figure 4 The first reduction drive gear assembly 43 comprises a reduction, a reduction driven gear 44, a first reduction gear shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com