Test device for treating petroleum hydrocarbon pollutants in underground water and application of test device

A test device, CNPC's technology, applied in the direction of water pollutants, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of inability to intuitively and accurately simulate the dispersion of oxidants, and achieve convenient replacement and reduce The effect of manufacturing cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

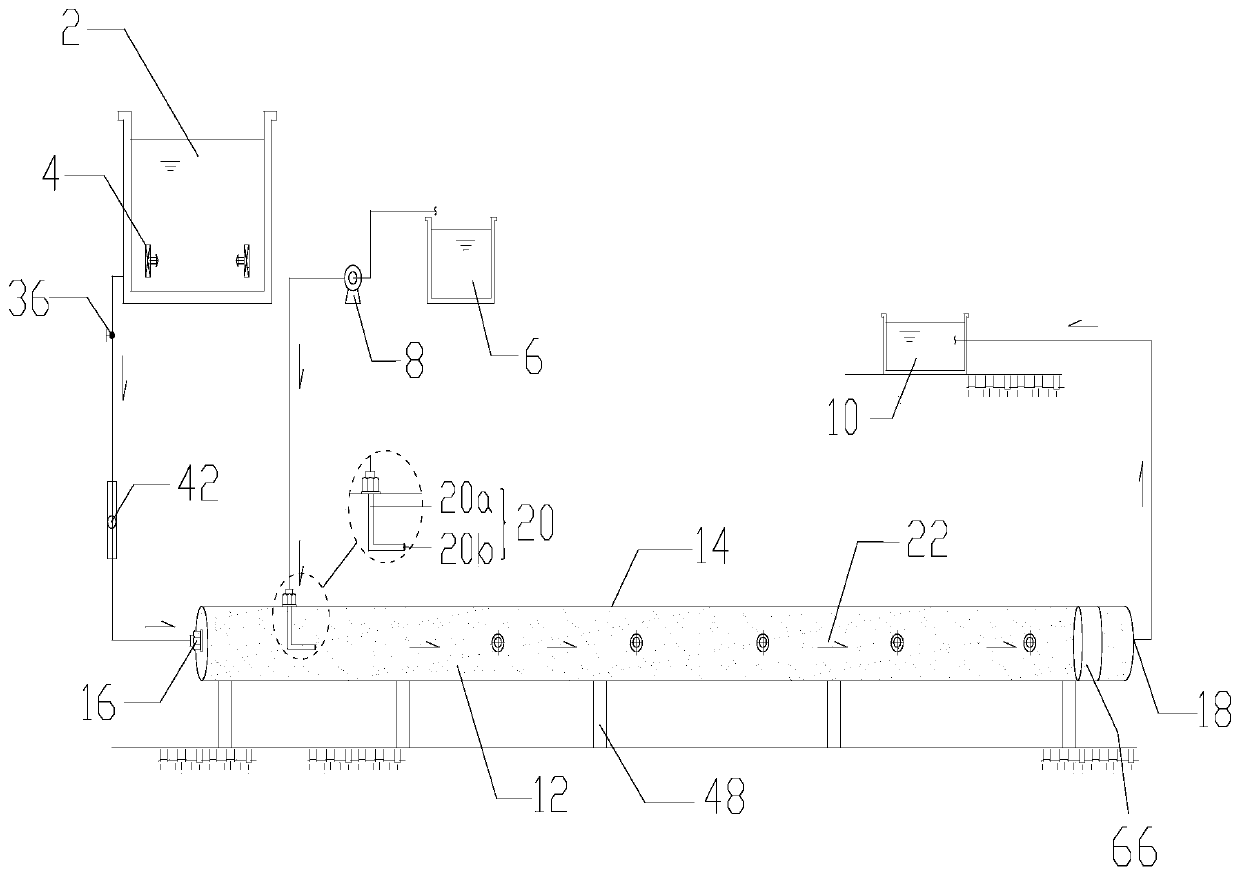

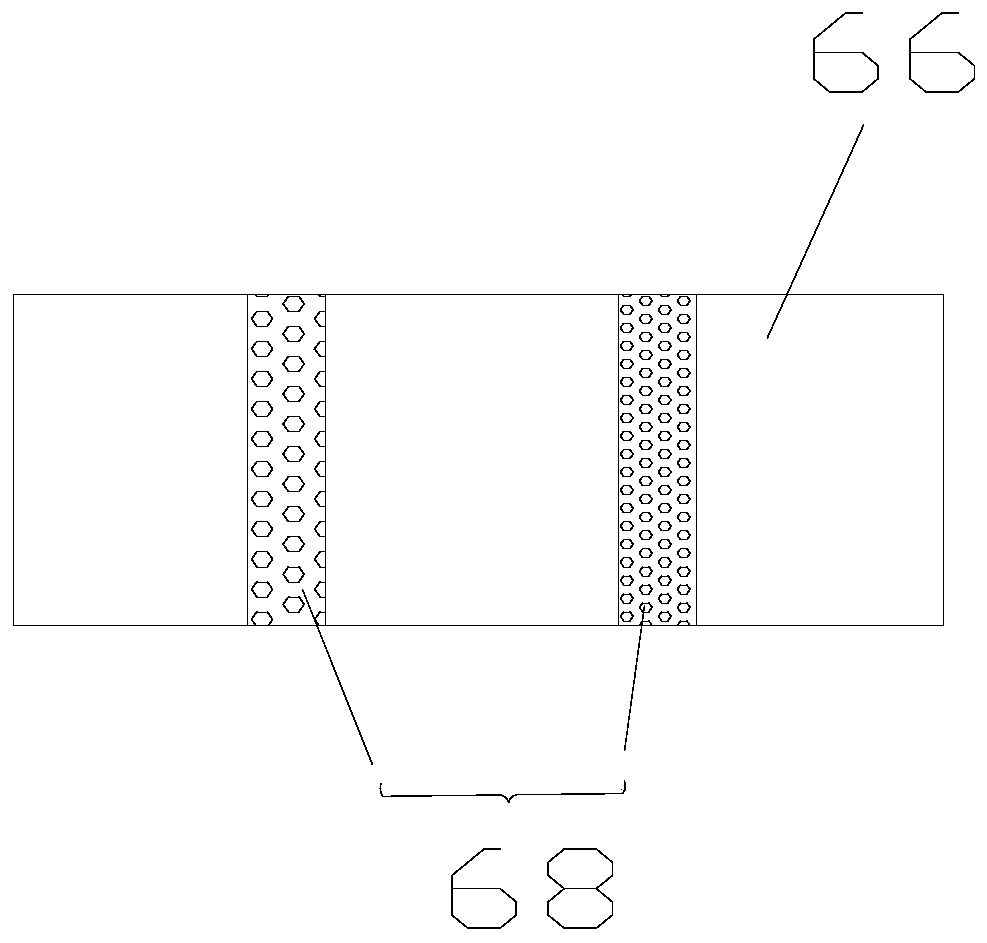

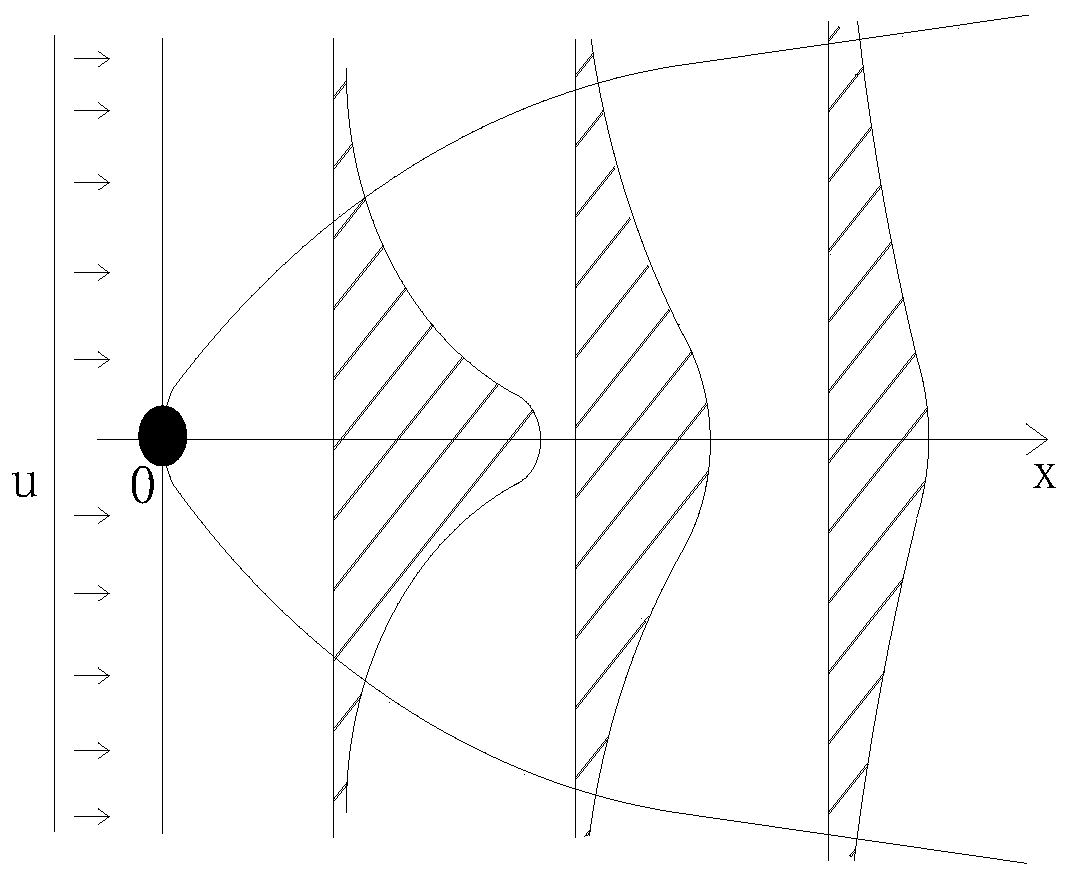

[0054] This embodiment provides a test device for treating petroleum hydrocarbon pollutants in groundwater, combining figure 1 and figure 2 As shown, it includes: including sewage container 2, submersible pump 4, oxidant container 6, oxidant injection pump 8, overflow tank 10, reaction column 14 and filter inner core 66, wherein, combined figure 1 and figure 2 As shown, the first end of the reaction column 14 is provided with a sewage injection port 16; the tail end of the reaction column 14 is provided with a liquid outlet 18; the inside of the reaction column 14 is filled with a seepage medium 12; from the sewage In the direction from the injection port 16 to the liquid discharge port 18, an oxidant injection pipe 20, at least two sampling ports 22 and a filter inner core 66 are arranged in sequence; figure 1 and figure 2 As shown, the liquid outlet end of the oxidant container 6 is connected to the liquid inlet end of the oxidant injection pump 8 through a pipeline; t...

Embodiment approach 2

[0076] This embodiment provides a test device for treating petroleum hydrocarbon pollutants in groundwater, combining Figure 1-2 As shown, it includes: including sewage container 2, submersible pump 4, oxidant container 6, oxidant injection pump 8, overflow tank 10, reaction column 14, filter inner core 66, valve 36, flow meter 42 and support 48, wherein, Such as figure 1 As shown, the first end of the reaction column 14 is provided with a sewage injection port 16; the tail end of the reaction column 14 is provided with a liquid outlet 18; the inside of the reaction column 14 is filled with a seepage medium 12; from the sewage In the direction from the injection port 16 to the liquid discharge port 18, an oxidant injection pipe 20, at least two sampling ports 22 and a filter inner core 66 are arranged in sequence, wherein the inner diameter of the reaction column 14 is 0.11 m, and the reaction column 14 The length is 11.1m, installed horizontally, and a sampling port is set ...

Embodiment approach 3

[0079] A method for processing petroleum hydrocarbon pollutants in groundwater using a test device for processing petroleum hydrocarbon pollutants in groundwater according to embodiment 2, the method includes the following steps:

[0080]S1. get concentration and be that the petroleum hydrocarbon pollutant water sample in groundwater of 5.52mg / L process injects sewage container for standby, get concentration and be that 251.96mg / L sodium ferrate oxidant is injected in oxidant container for standby;

[0081] S2. Fill the seepage medium 12 in the reaction column 14, start the submersible pump 4, and inject the petroleum hydrocarbon contaminated water sample in the sewage container 2 in the step S1 into the reaction column 14; start the oxidant injection pump 8 again, and turn the step S1 The oxidant in the middle oxidant container 6 is injected into the reaction column 14, the petroleum hydrocarbon contaminated water sample is oxidized in contact with the oxidant, and the oxidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com