Ozone disinfection and oxygenation all-in-one machine

An ozone disinfection, all-in-one technology, used in oxidized water/sewage treatment, special treatment targets, water/sludge/sewage treatment, etc. Uniform, non-moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

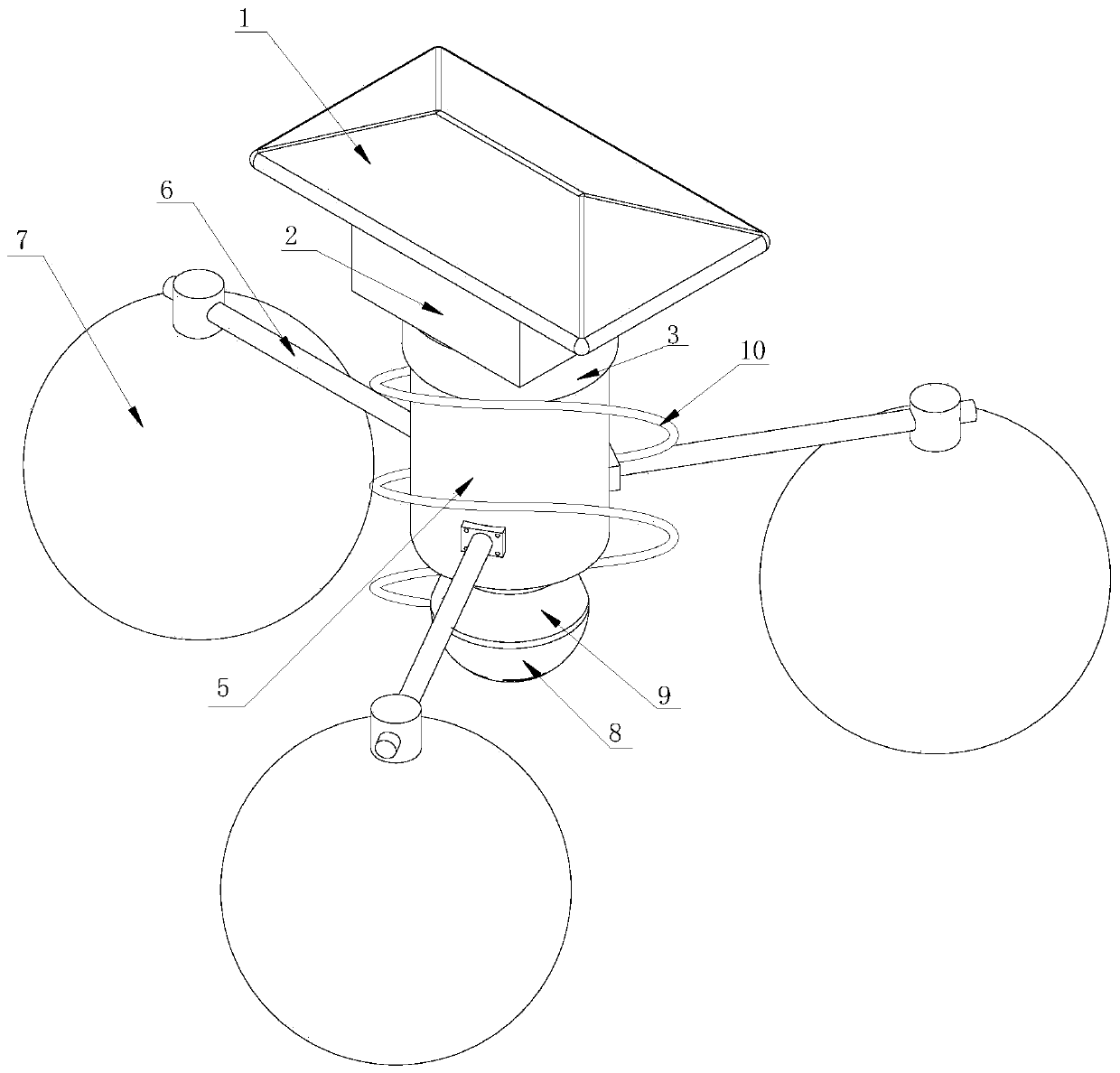

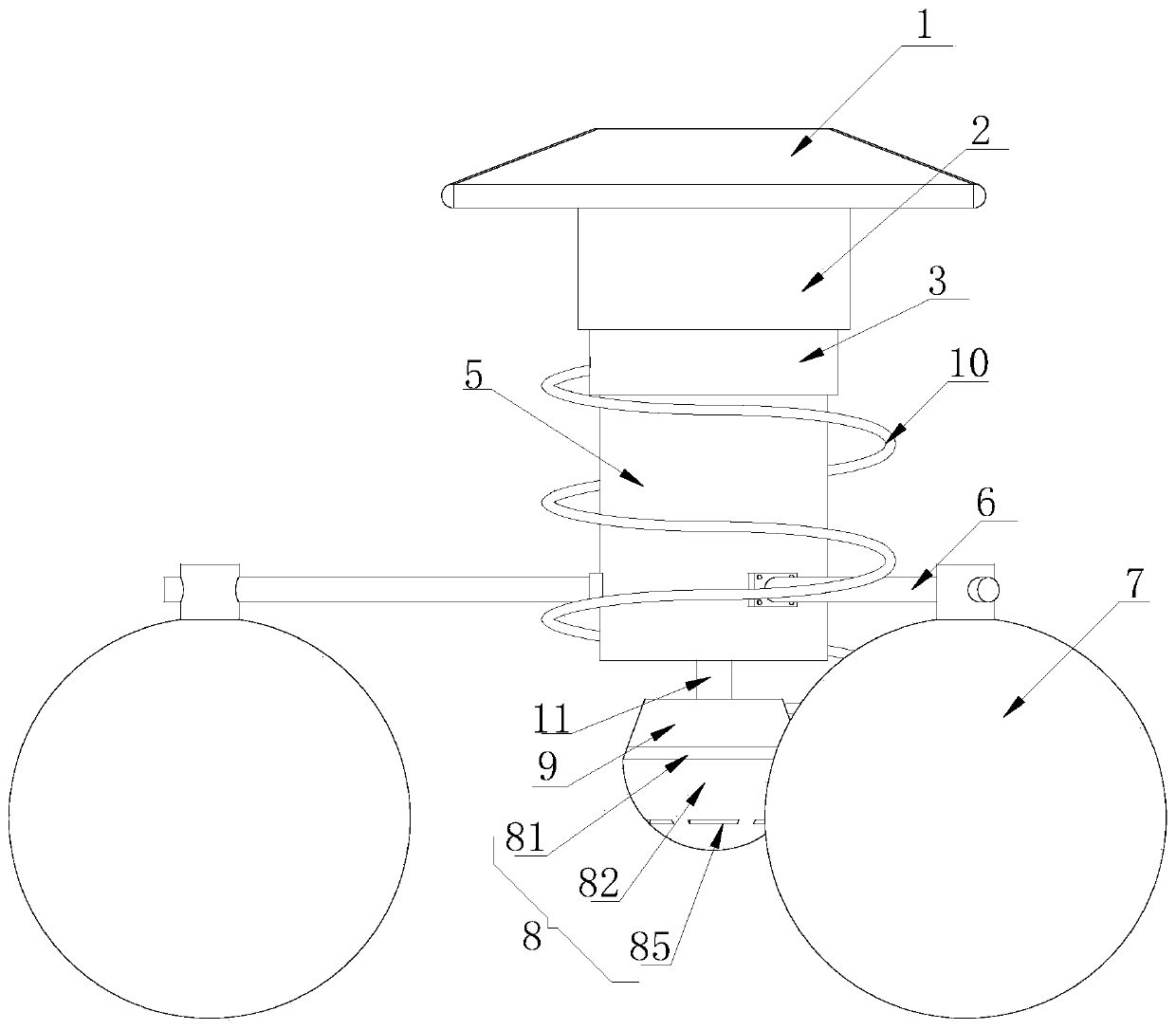

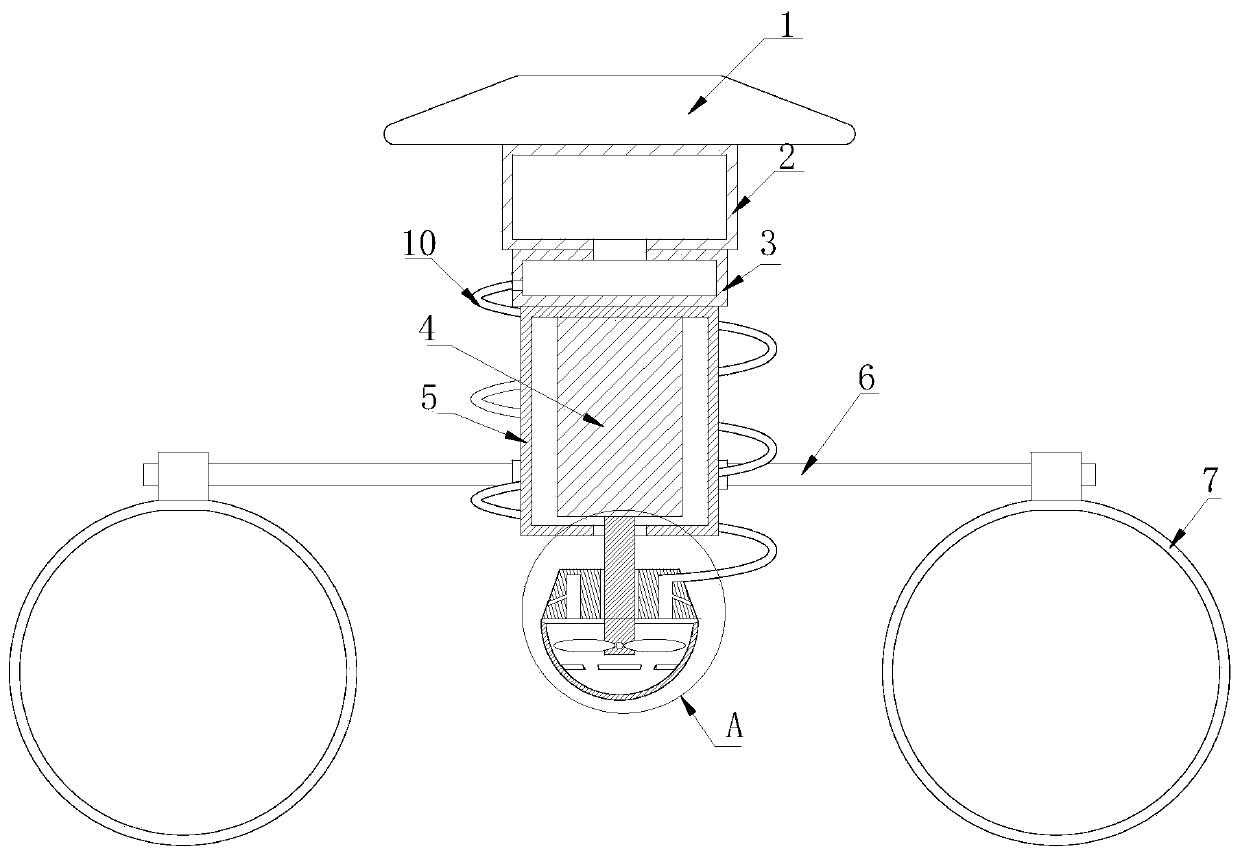

[0031] Such as Figure 1-6 As shown, the present invention provides a technical solution: an integrated ozone disinfection and oxygenation machine, including a shielding panel 1, an ozone generator 2, a fan 3, a reduction motor 4, a motor cover 5, a support rod 6, a floating body chamber 7, and an impeller Place the casing 8, the enhanced air chamber 9 and the spiral communication air chamber 10, the ozone generator 2 adopts a high-voltage discharge type, the fan 3 adopts a centrifugal fan, the shielding panel 1 is installed above the ozone generator 2, and the ozone generator 2 is installed on the fan 3 above, and the ozone generator 2 and the fan 3 are connected to each other, the bottom of the fan 3 is fixedly connected with the geared motor 4, the output end of the geared motor 4 is fixedly connected with the rotating shaft 11, and the bottom of the rotating shaft 11 is fixedly connected with a The impeller 12 inside the casing 8 and the outer side of the geared motor 4 ar...

Embodiment 2

[0034] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the impeller housing 8 includes an upper housing 81 and a lower housing 82, and the upper housing 81 and the lower housing 82 are clamped and connected, and the lower housing The body 82 is a hemispherical shell, and the bottom of the upper shell 21 is fixedly connected with a buckle 83, and the top of the lower shell 81 is fixedly connected with a limit groove 84 that is compatible with the buckle 83. The bottom of 81 is provided with a plurality of groups of air supply ports 85, and the bottom of the inner wall of the lower housing 81 is fixedly connected with a plurality of ring-shaped windshields 86, and the windshields 86 can be S-shaped or X-shaped extruded windshields Plate, upper air inlet and upper air outlet and its internal S-shaped or X-shaped windshield through the high-speed rotation of the blades to generate turbine extrusion wind. The setting ...

Embodiment 3

[0036] Such as Figure 1-6As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the reinforced air chamber 9 includes a plastic cylinder 91, and the upper and lower ports of the plastic cylinder 91 are connected with the ports and ports of the reinforced air chamber 9 respectively. The port of the impeller housing 8 is tightly connected, and the bottom of the plastic cylinder 91 is provided with a plurality of ring-shaped vertical grooves 92. 93, and the chute 93 is connected with the plastic cylinder 91, the caliber of the chute 93 is far smaller than the caliber of the vertical groove 92, and the plurality of vertical grooves 92 are connected to each other through the groove body, the outer surface of the chute 93 The caliber along the place becomes smaller, and the direction of the chute body 93 is set downward, which can blow to the water surface more conveniently. The design of the vertical groove 92 and the chute mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com