Method for preparing microcrystalline glass ceramic composite bricks from waste glass

A technology for glass-ceramics and waste glass, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of high sales price, low qualified rate of finished products, high production cost, and achieve uniform and dense overall structure. , excellent mechanical properties, the effect of improving melting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

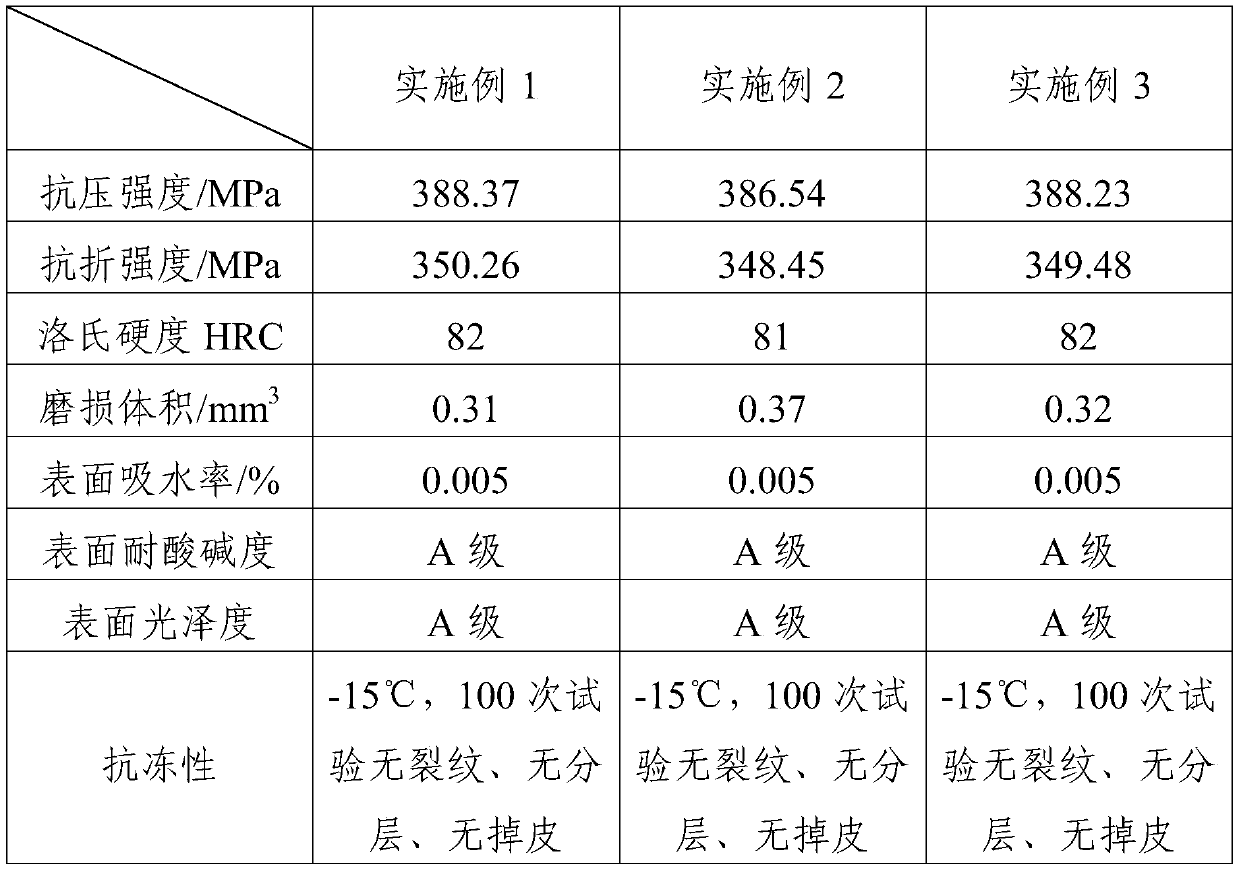

Embodiment 1

[0029] A method for preparing glass-ceramic composite bricks by using waste glass:

[0030]The iron tailings are subjected to wet ball milling. During ball milling, the weight ratio of balls:iron tailings:hydrogen peroxide:water is 85:22:3:50, ground to a particle size of 0.05-0.1mm, and dried at 60°C to obtain iron The tailings powder is ready for use, and the waste glass is crushed and ball-milled to a particle size of 1-5 μm to obtain the waste glass powder, and the iron tailings powder, waste glass powder, soda ash, titanium dioxide, zirconium dioxide, calcium fluoride, and three Chromium oxide is mixed with a crystal nucleating agent composed of a mass ratio of 45:8:5:1 and placed on a planetary ball mill to grind and mix for 10 hours to obtain a mixture. The weight ratio of iron tailings powder, waste glass powder, soda ash, and crystal nucleating agent The ratio is 8:35:2:1, put the mixture into the crucible, place it in a silicon-molybdenum rod high-temperature lifting...

Embodiment 2

[0032] A method for preparing glass-ceramic composite bricks by using waste glass:

[0033] The iron tailings are subjected to wet ball milling. During ball milling, the weight ratio of balls:iron tailings:hydrogen peroxide:water is 100:20:3:58, ground to a particle size of 0.05-0.1mm, and dried at 50°C to obtain iron The tailings powder is ready for use, and the waste glass is crushed and ball-milled to a particle size of 1-5 μm to obtain the waste glass powder, and the iron tailings powder, waste glass powder, soda ash, titanium dioxide, zirconium dioxide, calcium fluoride, and three Chromium oxide is mixed with a crystal nucleating agent composed of a mass ratio of 48:7:10:1 and placed on a planetary ball mill to grind and mix for 11 hours to obtain a mixture. The weight ratio of iron tailings powder, waste glass powder, soda ash, and crystal nucleating agent The ratio is 8:35:1:1, put the mixture into the crucible, place it in a silicon-molybdenum rod high-temperature lift...

Embodiment 3

[0035] A method for preparing glass-ceramic composite bricks by using waste glass:

[0036] The iron tailings are subjected to wet ball milling. During ball milling, the weight ratio of balls:iron tailings:hydrogen peroxide:water is 90:25:3:55, ground to a particle size of 0.05-0.1mm, and dried at 60°C to obtain iron The tailings powder is ready for use, and the waste glass is crushed and ball-milled to a particle size of 1-5 μm to obtain the waste glass powder, and the iron tailings powder, waste glass powder, soda ash, titanium dioxide, zirconium dioxide, calcium fluoride, and three Chromium oxide is mixed with a crystal nucleating agent composed of a mass ratio of 42:8:7:1 and placed on a planetary ball mill for grinding and mixing for 12 hours to obtain a mixture. The weight ratio of iron tailings powder, waste glass powder, soda ash, and crystal nucleating agent The ratio is 6:35:2:1, put the mixture into the crucible, put it in a silicon-molybdenum rod high-temperature l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com