Ardealite solid waste regenerated energy-saving green environment-friendly material coagulant and preparation method thereof

An energy-saving, environment-friendly, green and environment-friendly technology, applied in cement production, household refrigeration equipment, lighting and heating equipment, etc., can solve the problem that building materials are difficult to meet the use requirements of light weight, environmental protection, energy saving, high efficiency and high quality, and building materials are difficult to achieve high-efficiency utilization value , It is difficult to realize the inherent properties of the semi-air-hard material of gypsum products, etc., to achieve the effects of increasing suspension time, improving blowing efficiency, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: A kind of regenerated green energy-saving and environment-friendly new material coagulant, coagulant is made of following specific gravity raw material: Phosphogypsum 40~70%; Limestone 15~20%; Slag 5~10%; Bentonite 3~5%; Sex stimulant 1%;

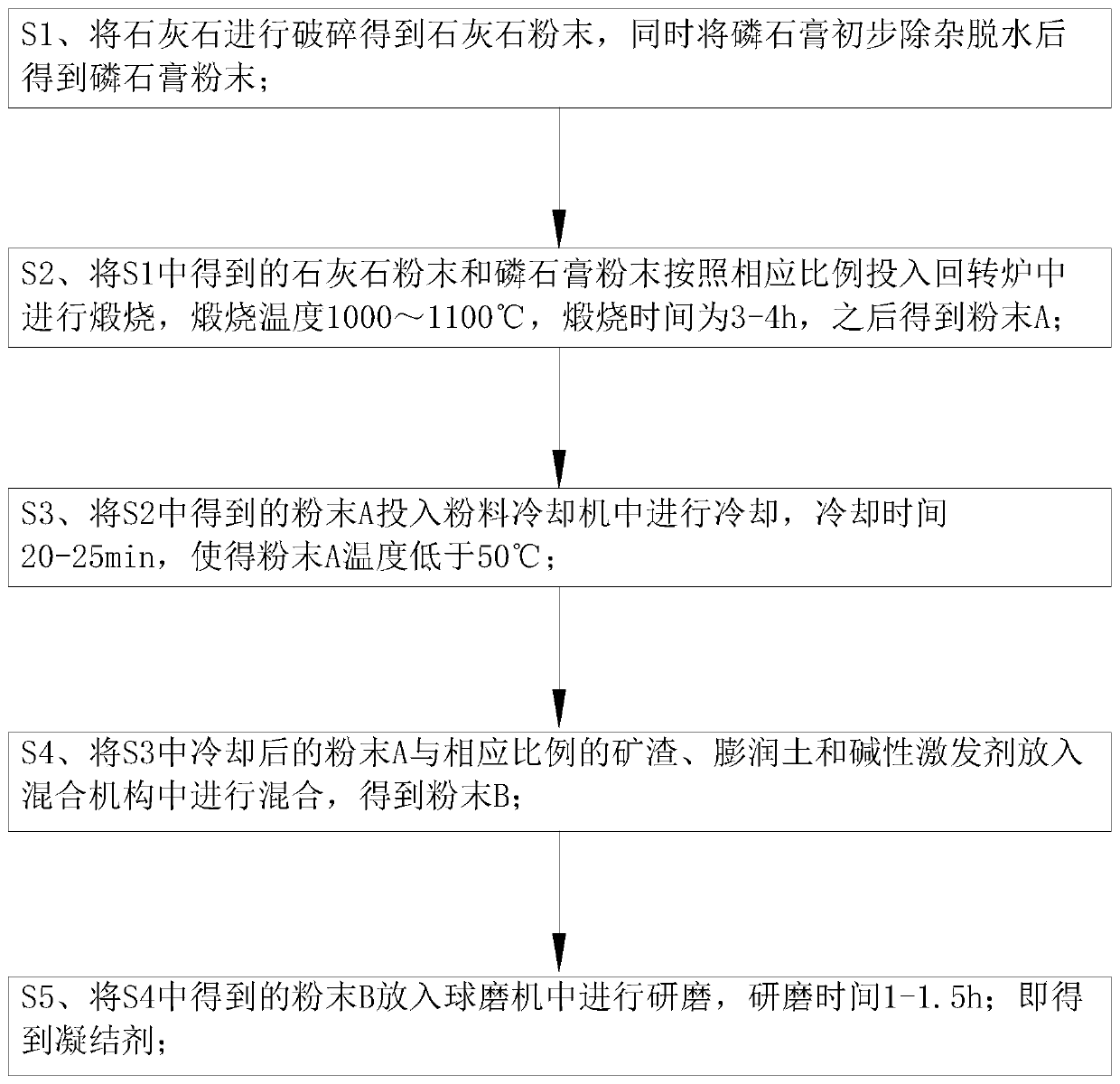

[0040] And the above-mentioned specific gravity raw material is prepared by the preparation method of the regenerated green, energy-saving and environment-friendly new material coagulant; the preparation method comprises the following steps:

[0041] S1, crushing the limestone to obtain limestone powder, and at the same time initially removing impurities and dehydrating the phosphogypsum to obtain phosphogypsum powder;

[0042] S2. Put the limestone powder and phosphogypsum powder obtained in S1 into a rotary furnace for calcination according to the corresponding ratio. The calcination temperature is 1000-1100° C., and the calcination time is 3-4 hours, and then powder A is obtained;

[0043] S3, put the powder A obtai...

Embodiment 2

[0047] Embodiment 2: A new coagulant for renewable green, energy-saving and environment-friendly materials. The coagulant is made of the following specific gravity raw materials: 40-70% of phosphogypsum; 15-20% of limestone; 5-10% of slag; 3-5% of bentonite; Sex stimulants 2%;

[0048] And the above-mentioned specific gravity raw material is prepared by the preparation method of the regenerated green, energy-saving and environment-friendly new material coagulant; the preparation method comprises the following steps:

[0049] S1, crushing the limestone to obtain limestone powder, and at the same time initially removing impurities and dehydrating the phosphogypsum to obtain phosphogypsum powder;

[0050] S2. Put the limestone powder and phosphogypsum powder obtained in S1 into a rotary furnace for calcination according to the corresponding ratio. The calcination temperature is 1000-1100° C., and the calcination time is 3-4 hours, and then powder A is obtained;

[0051] S3, put ...

Embodiment 3

[0055] Embodiment 3: A new coagulant for renewable green, energy-saving and environment-friendly materials. The coagulant is made of the following specific gravity raw materials: 40-70% of phosphogypsum; 15-20% of limestone; 5-10% of slag; 3-5% of bentonite; alkali Sex stimulants 3%;

[0056] And the above-mentioned specific gravity raw material is prepared by the preparation method of the regenerated green, energy-saving and environment-friendly new material coagulant; the preparation method comprises the following steps:

[0057] S1, crushing the limestone to obtain limestone powder, and at the same time initially removing impurities and dehydrating the phosphogypsum to obtain phosphogypsum powder;

[0058] S2. Put the limestone powder and phosphogypsum powder obtained in S1 into a rotary furnace for calcination according to the corresponding ratio. The calcination temperature is 1000-1100° C., and the calcination time is 3-4 hours, and then powder A is obtained;

[0059] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com