Nanopore thermal insulation material and preparation method thereof

A thermal insulation material and nanopore technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of difficult machining, easy powder and slag drop, high manufacturing cost, etc., and achieve high service temperature and thermal insulation performance Good, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

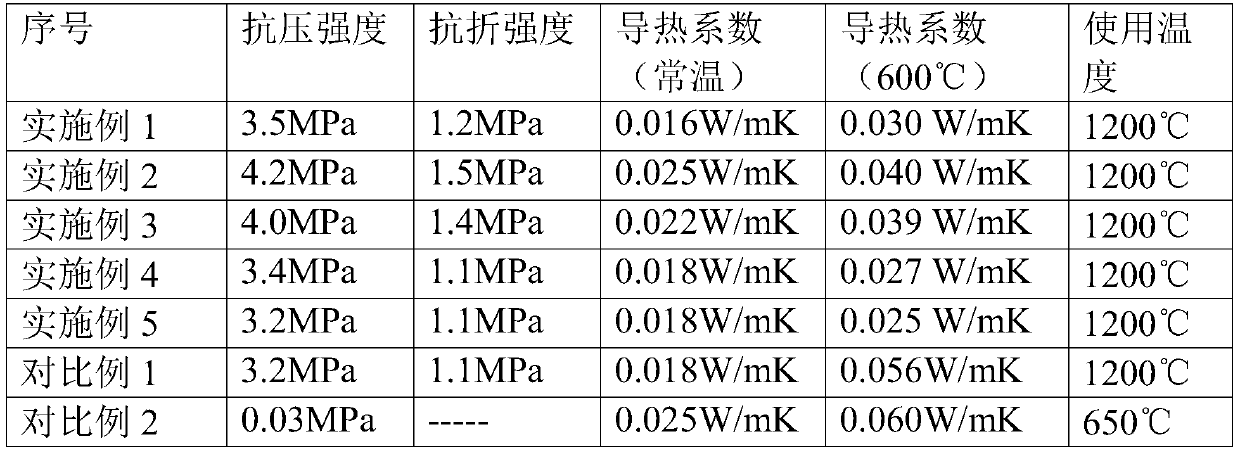

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing a nanoporous heat insulating material, comprising the following steps:

[0039] 1) Dilute 5 parts by weight of the phenolic resin with water to a solid phase content of 40wt%;

[0040] 2) Mix and stir the thermosetting resin dilution obtained in step 1) with 83 parts by weight of nano-powder and 2 parts by weight of an opacifying agent (the stirring speed is 1000 rpm, and the stirring time is 10 minutes);

[0041] 3) under high-speed stirring condition, the polyurethane foam of 10 weight parts (with the polyether polyol of 45wt%, the isocyanate of 50wt%, the catalyst of 1wt%, the tensio-active agent of 2wt% and the water of 2wt% in 1500-3000 turn Stir at a high speed for 5-20 minutes at a rotating speed of 1 / min to obtain the polyurethane foam) and mix the particles obtained in step 2) evenly (the stirring speed is 3000 rev / min, and the stirring time is 10 minutes);

[0042] 4) Pour the viscous granules obtained in step 3...

Embodiment 2

[0046] This embodiment provides a method for preparing a nanoporous heat insulating material, comprising the following steps:

[0047] 1) Dilute 30 parts by weight of the phenolic resin with absolute ethanol to a solid phase content of 10 wt%;

[0048] 2) Mix and stir the thermosetting resin diluent obtained in step 1) with 30 parts by weight of nano-powder and 5 parts by weight of an opacifying agent (the stirring speed is 800 rpm, and the stirring time is 10 minutes);

[0049] 3) under high-speed stirring condition, the polyurethane foam of 10 weight parts (with the polyether polyol of 45wt%, the isocyanate of 50wt%, the catalyst of 1wt%, the tensio-active agent of 2wt% and the water of 2wt% in 1500-3000 turn Stir at a high speed for 5-20 minutes at a rotating speed of 1 / min to obtain the polyurethane foam) and mix the particles obtained in step 2) evenly (the stirring speed is 2500 rev / min, and the stirring time is 15 minutes);

[0050] 4) Pour the viscous granules obtaine...

Embodiment 3

[0054] This embodiment provides a method for preparing a nanoporous heat insulating material, comprising the following steps:

[0055] 1) Dilute the epoxy resin of 15 parts by weight with absolute ethanol to a solid phase content of 20wt%;

[0056] 2) Mix and stir the thermosetting resin dilution obtained in step 1) with 40 parts by weight of nano-powder and 5 parts by weight of an opacifying agent (the stirring speed is 1000 rpm, and the stirring time is 5 minutes);

[0057] 3) under high-speed stirring condition, the polyurethane foam of 40 weight parts (with the polyether polyol of 45wt%, the isocyanate of 50wt%, the catalyst of 1wt%, the tensio-active agent of 2wt% and the water of 2wt% in 1500-3000 turn Stir at a high speed for 5-20 minutes at a rotating speed of 1 / min to obtain the polyurethane foam) and mix the particles obtained in step 2) evenly (the stirring speed is 3000 rev / min, and the stirring time is 10 minutes);

[0058] 4) Pour the viscous granules obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com