A kind of gh3039 superalloy rod and its preparation method

A technology of GH3039 and superalloy, which is applied in the field of GH3039 superalloy rods, can solve the problems of not comprehensively considering the correlation, etc., and achieve the effect of eliminating coarse grains, uniform composition of rods, high strength and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The ingot is smelted according to the set composition, and its composition contains C 0.046%, Si 0.038%, Mn0.30%, Mo 2.05%, Al 0.54%, Ti 0.68%, Fe 0.65%, Cu 0.0052%, Cr 20.41% by weight , Nb1.04%, S 0.0002%, P 0.0078%, and the balance is Ni and unavoidable inclusions.

[0047] The GH3039 alloy ingot smelted by vacuum induction melting + electroslag remelting process has a diameter of 660mm. The ingot is opened at 1100°C. There are 4 forgings in total. The deformation settings are as follows: Φ660×1000→Φ740×800→Bafang 630 ×1040→Bafang 750×730→Bafang 620×1070, the deformation of the 1st-4th single fire is 20%, 23%, 30%, 32% respectively, after the completion, the hot material is water quenched and cooled.

[0048] The billet with square cross-section is kept at 1180°C for 40 hours for annealing and homogenization, and then air-cooled after completion;

[0049] After the billet is kept at 1070°C for 6 times of upsetting and drawing deformation, the settings are as follows...

Embodiment 2

[0054] The ingot is smelted according to the set composition, and its composition contains C 0.046%, Si 0.038%, Mn0.30%, Mo 2.05%, Al 0.54%, Ti 0.68%, Fe 0.65%, Cu 0.0052%, Cr 20.41% by weight , Nb1.04%, S 0.0002%, P 0.0078%, and the balance is Ni and unavoidable inclusions.

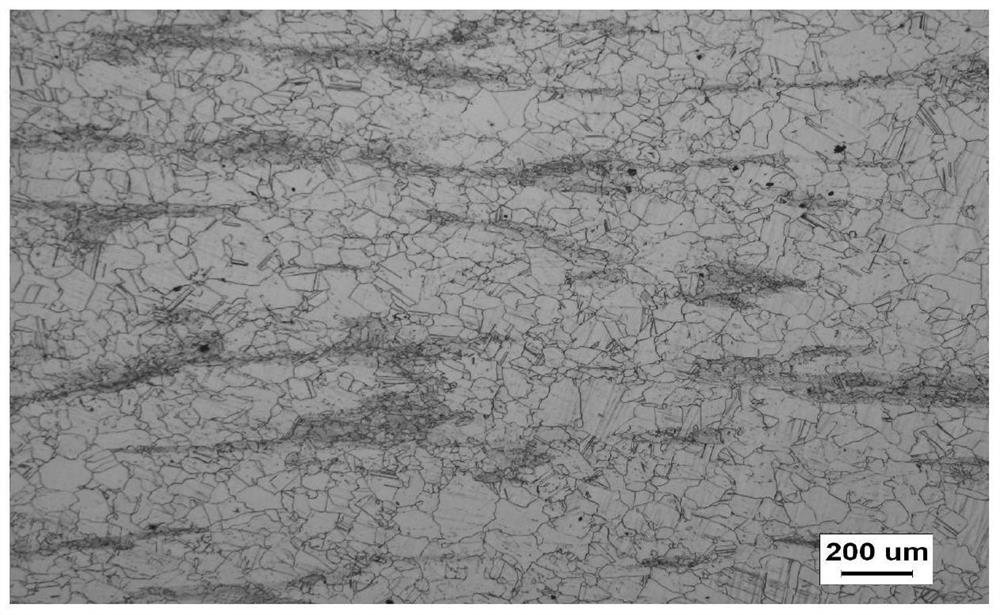

[0055] The GH3039 alloy ingot smelted by vacuum induction melting + electroslag remelting process has a diameter of 580mm, and the ingot is opened at 1100°C. There are 3 forgings in total. The deformation settings are as follows: Φ580×1000→Φ650×800→Bafang 555 ×1030→Bafang 670×710, the deformations of the 1st to 3rd single fires are 20%, 23%, and 31% respectively. After completion, the hot material is quenched in water, and the high-magnification structure diagram of the material after blanking is as follows figure 1 shown.

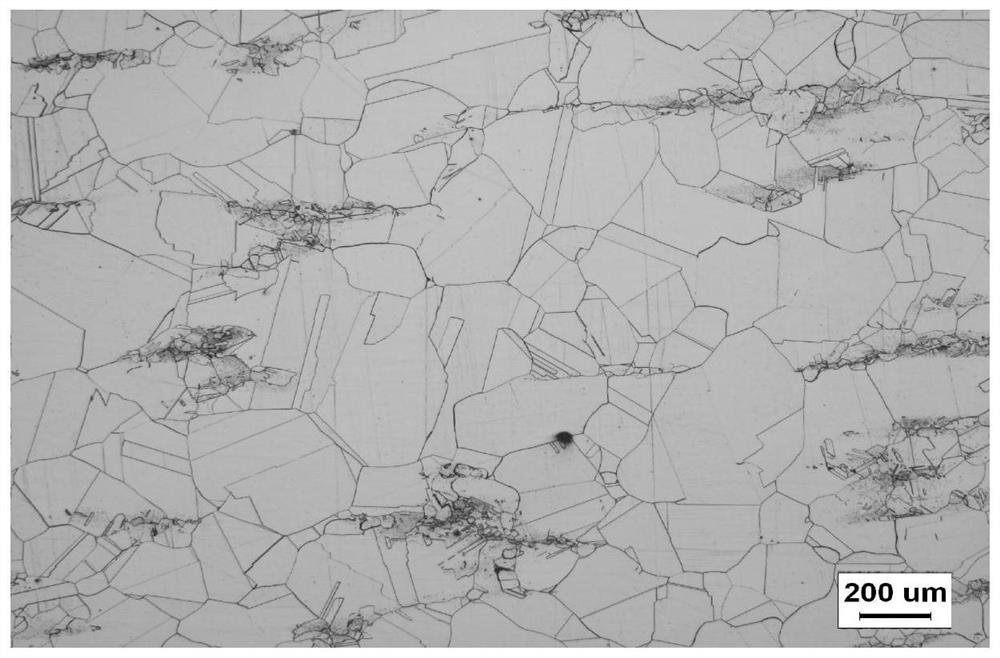

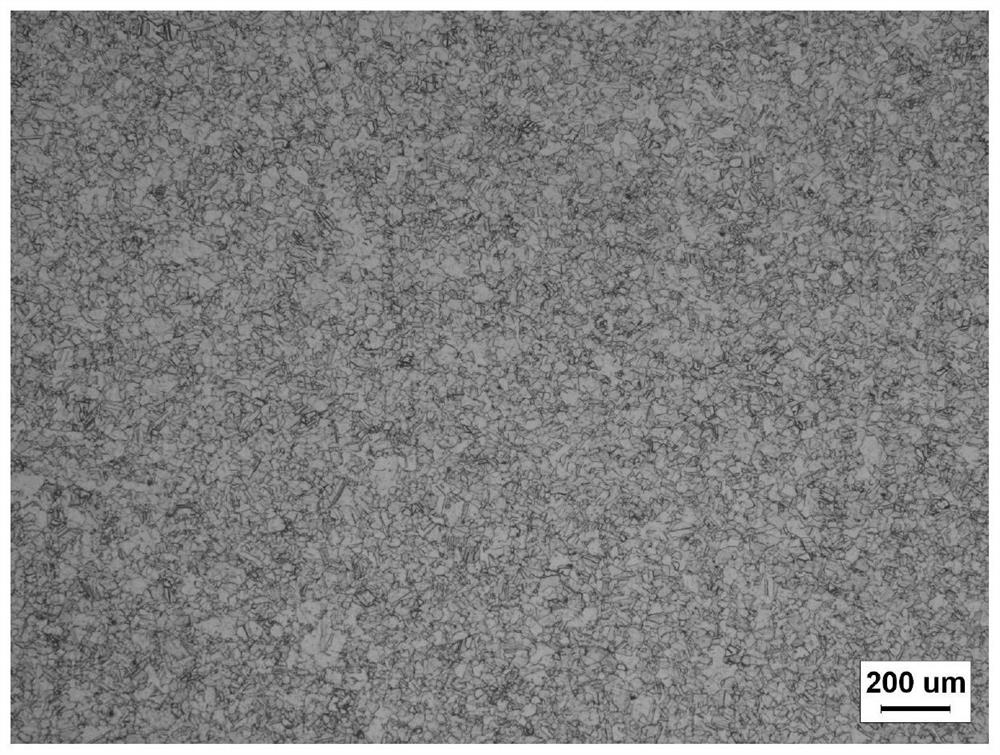

[0056] Anneal and homogenize the billet with octagonal cross-section at 1190°C for 40 hours, and air cool after completion; the high-magnification structure diagram of the intermed...

Embodiment 3

[0063] The ingot is smelted according to the set composition, and its composition contains C 0.046%, Si 0.038%, Mn0.30%, Mo 2.05%, Al 0.54%, Ti 0.68%, Fe 0.65%, Cu 0.0052%, Cr 20.41% by weight , Nb1.04%, S 0.0002%, P 0.0078%, and the balance is Ni and unavoidable inclusions.

[0064] The GH3039 alloy ingot smelted by vacuum induction melting + electroslag remelting process has a diameter of 500mm, and the ingot is opened at 1120°C. There are 3 forgings in total. The deformation settings are as follows: Φ500×1000→Φ615×800→Bafang 480 ×1030→Bafang 580×710→Bafang 480×1030→Bafang 580×710, the deformations of the 1st to 5th fires are 20%, 23%, 31%, 31%, and 31%, respectively. After completion, the hot material is quenched in water to obtain a billet with a square cross section.

[0065] The billet with square cross-section is kept at 1170°C for 34 hours for annealing and homogenization, and then air-cooled after completion;

[0066] After the billet is kept at 1050°C for 7 times o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com