Coal-fired coupling garbage incineration system

A waste incineration and waste incinerator technology, applied in the field of waste incineration power generation technology and coal-fired power generation, can solve the problems of large waste incineration power plants with huge investment, lack of market competitiveness, high operating costs, etc., to improve stability and combustion efficiency , reduce the impact, improve the effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

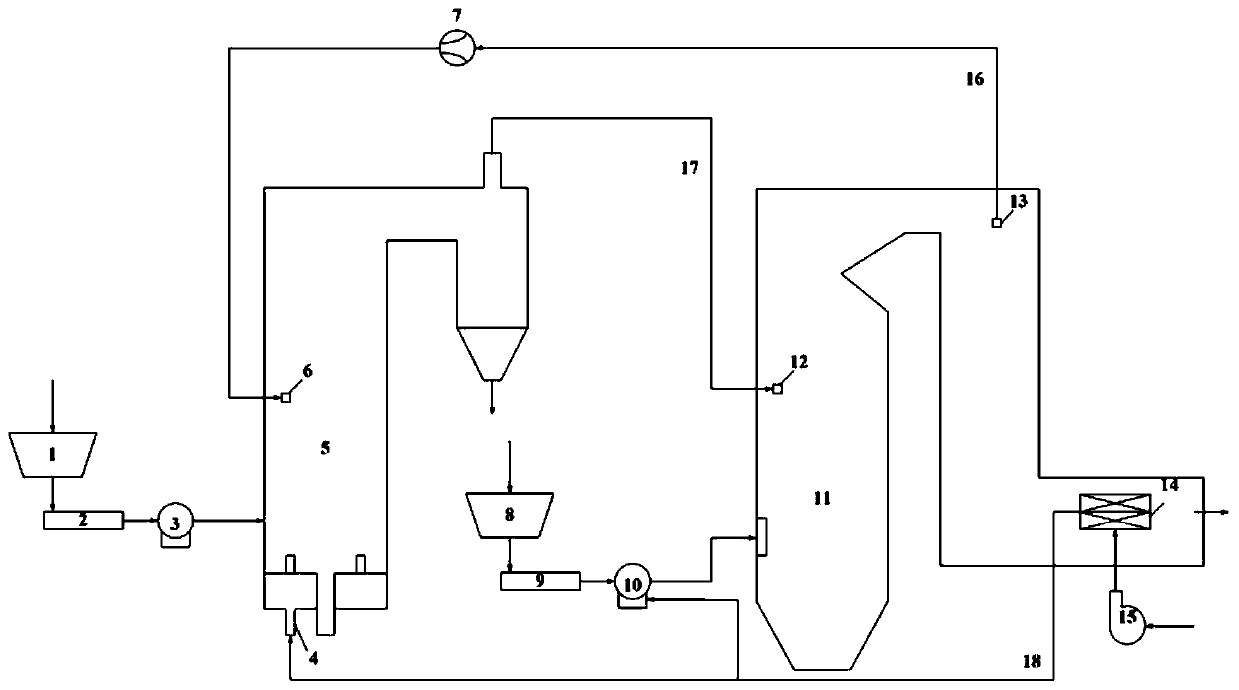

[0015] The present invention provides a coal-fired coupled waste incineration system, including a waste hopper 1, a feeder 2, a crusher 3, a fluidized bed waste incinerator 5, a flue gas ejector 7, a coal hopper 8, and a coal feeder 9. Coal mill 10, pulverized coal furnace 11, air preheater 14, air blower 15.

[0016] The garbage in the garbage hopper 1 enters the crusher 3 through the feeder 2 and is broken into garbage particles, the crusher 3 is connected with the fluidized bed garbage incinerator 5, and the coal in the coal hopper 8 enters the coal mill 10 through the coal feeder 9 To grind into pulverized coal, the coal pulverizer 10 is connected with the pulverized coal furnace 11. The air enters the air preheater 14 through the blower 15, and the hot air 18 is divided into two paths, one path is sent to the fluidized bed waste incinerator 5 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com