Normal-pressure single-effect evaporator of heat pump and use method of evaporator

A single-effect evaporation and normal pressure technology, which is applied in the direction of evaporator/condenser, heat pump, lighting and heating equipment, etc., can solve the problems of difficult detection, high system cost, damage to the vacuum degree of the system, etc., achieve stable operation and reduce cost cost, the effect of increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

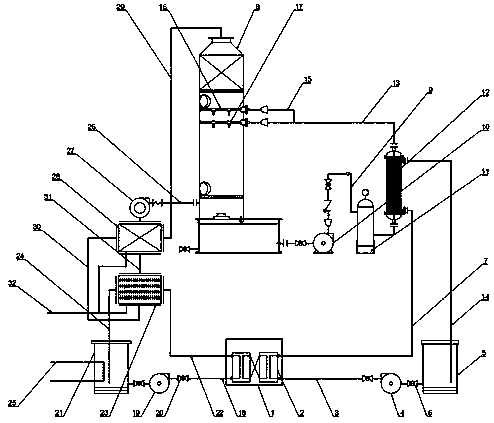

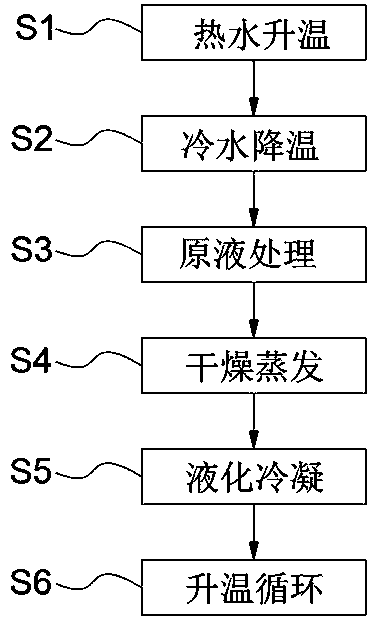

[0033] Example: such as Figure 1-2As shown, the present invention provides a technical solution, a heat pump atmospheric pressure single-effect evaporator, including a heat pump unit 1, the selection of the heat pump unit 1 is M-08, the heat pump unit 1 includes a refrigerant compressor and an evaporator, and the refrigerant compression The evaporator is mainly used to compress the refrigerant, and the evaporator is mainly used to reduce the pressure of the refrigerant to achieve refrigeration, which is convenient for the refrigerant to be compressed and depressurized for refrigeration. The heat pump unit 1 is equipped with a coil heat exchanger 2 inside, and the bottom position of the heat pump unit 1 is The hot water supply pipe 3 is connected to the hot water supply pipe 3, and the end of the hot water supply pipe 3 far away from the heat pump unit 1 is connected to the hot water buffer tank 5. The selected model is P701, hot water pipe valve 6 is installed on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com