All-solid-state variable-focus electrostatic drive type micro lens based on PDMS film

A technology of electrostatic drive and microlens, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of zoom range, electromagnetic interference, liquid leakage, etc., achieve wide focusing range, fast response speed, solve liquid leakage and Effects of Electromagnetic Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

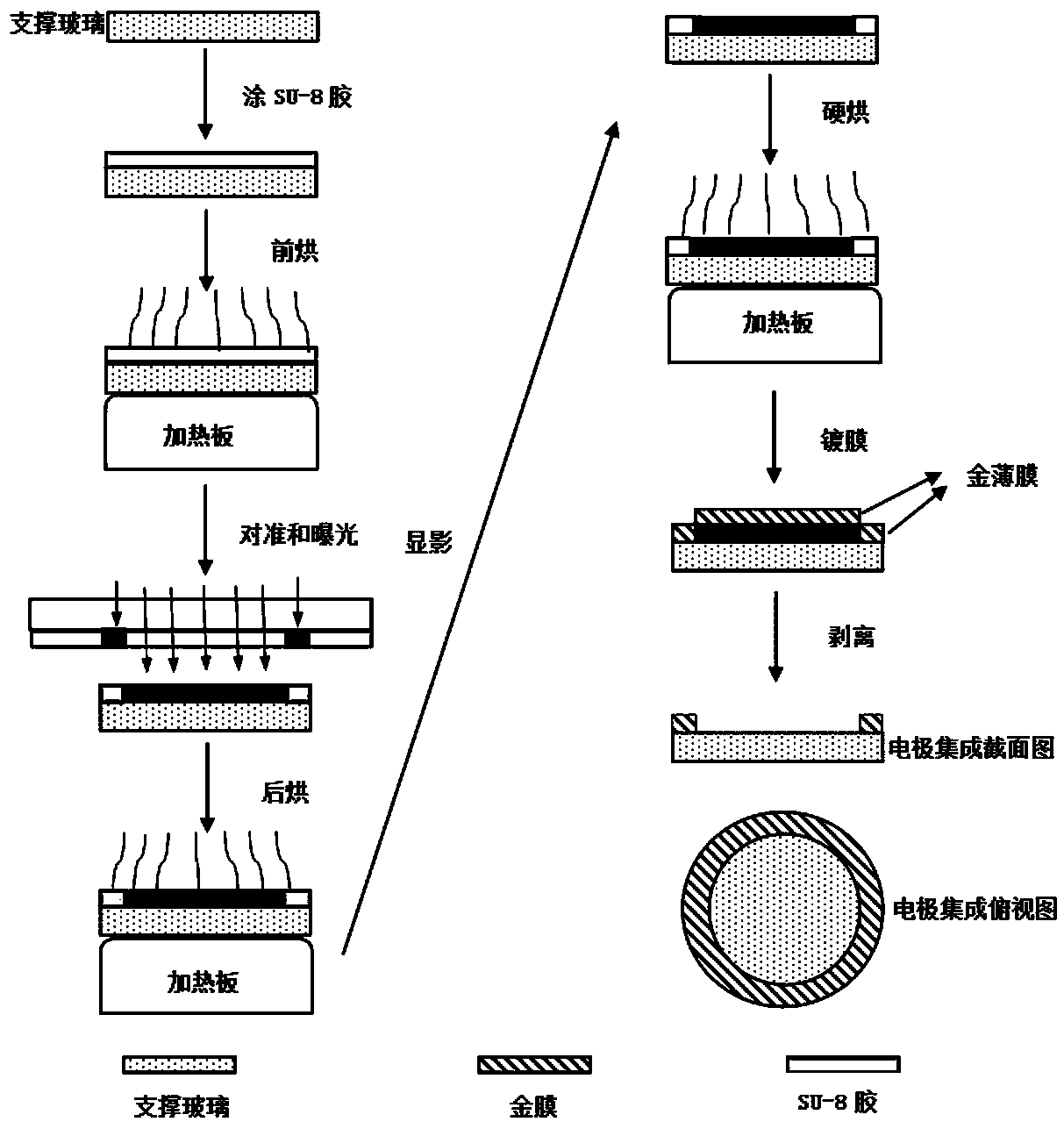

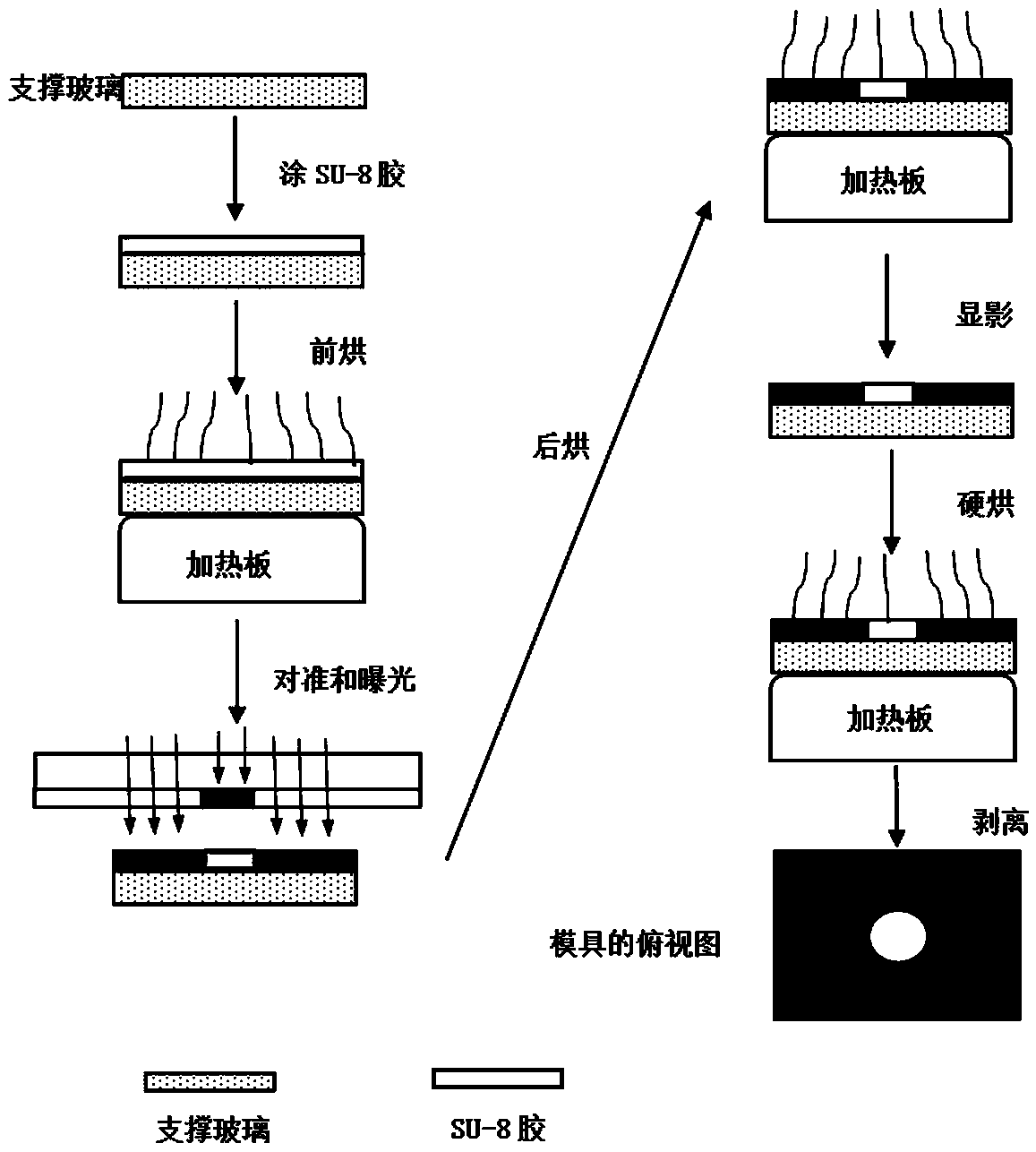

Method used

Image

Examples

Embodiment 1

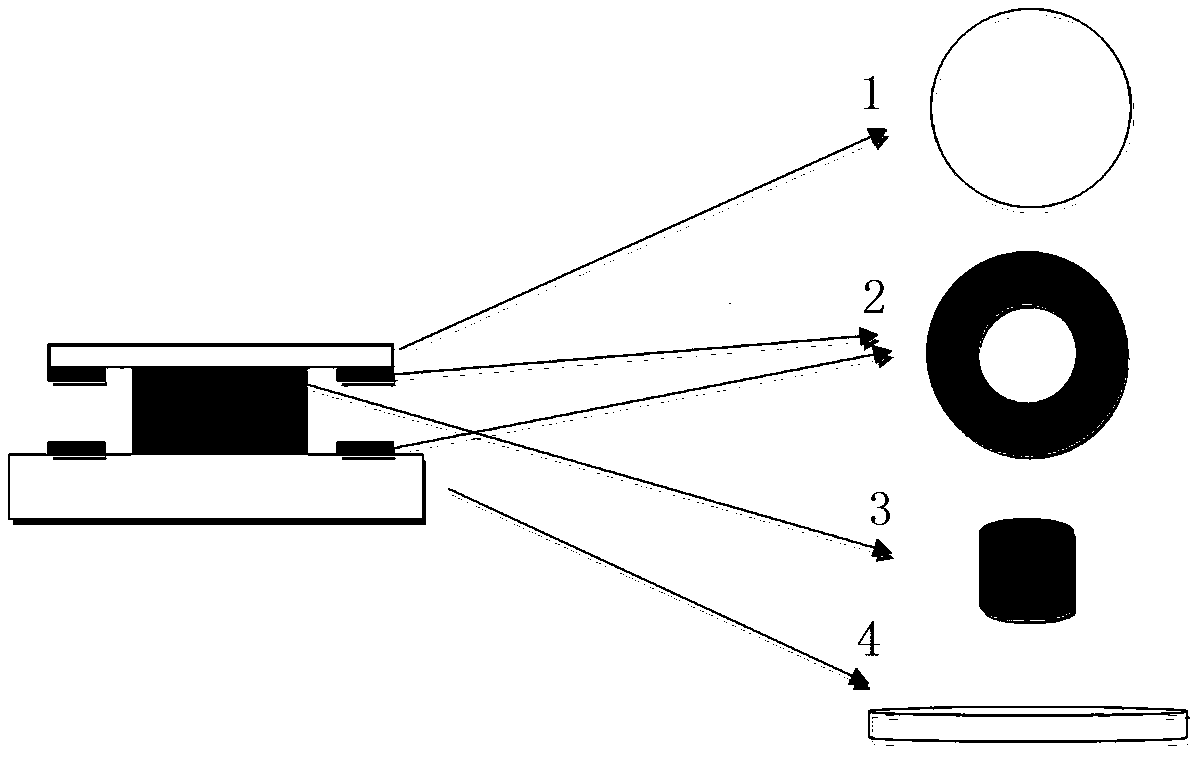

[0056] A variable focus microlens, its glass film 1 is silica glass with a thickness of 50 μm, and the PDMS film 3 is made of Dow Corning SYLRARD184. The glass film 1 is harder than the PDMS film 3 and less likely to be deformed; the supporting glass 4 is ordinary glass.

[0057] Production of glass film: Cut a circular glass film with a diameter of 4mm with a laser cutting machine.

[0058] Fabrication of support glass: Cut a circular glass piece with a diameter of 4mm with a glass cutter.

[0059] The full name of MEMS is Micro Electromechanical System, which refers to an electromechanical composite device with a size of a few millimeters or even smaller. Its internal structure is generally on the order of microns or even nanometers, and it is an independent intelligent system. It is mainly composed of three parts: sensors, actuators (actuators) and micro energy sources. Common products include micro accelerometers, micro motors, micro displacement drivers, etc. and their ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com