Plasma surface modification device for improving carbon deposition resistance of spark plug

A plasma and surface modification technology, which is applied in the field of spark plugs, can solve problems such as inability to uniformly treat the surface, achieve the effects of improving surface electrical properties, optimizing ignition and fuel injection control strategies, and solving the effect of surface carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

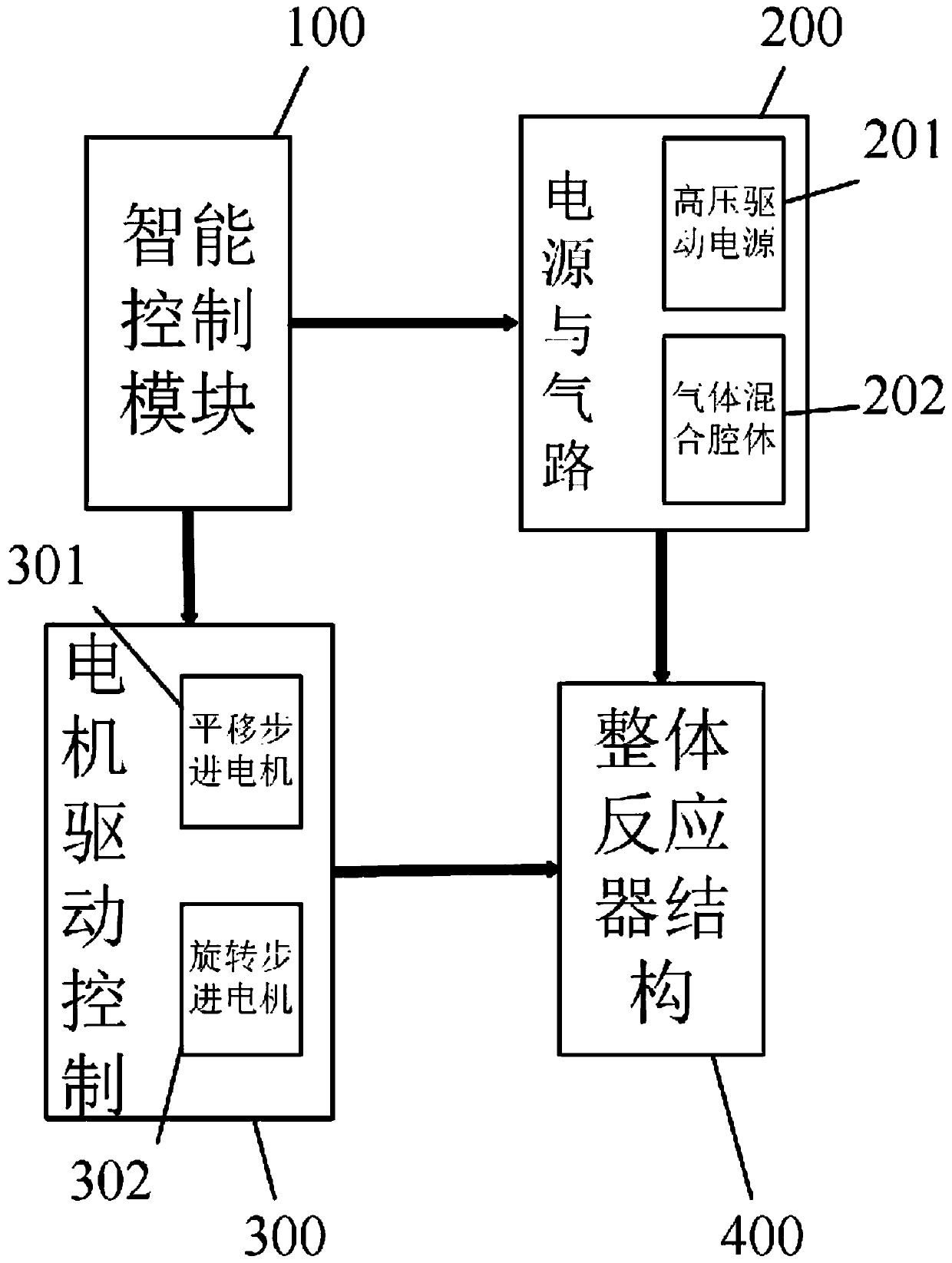

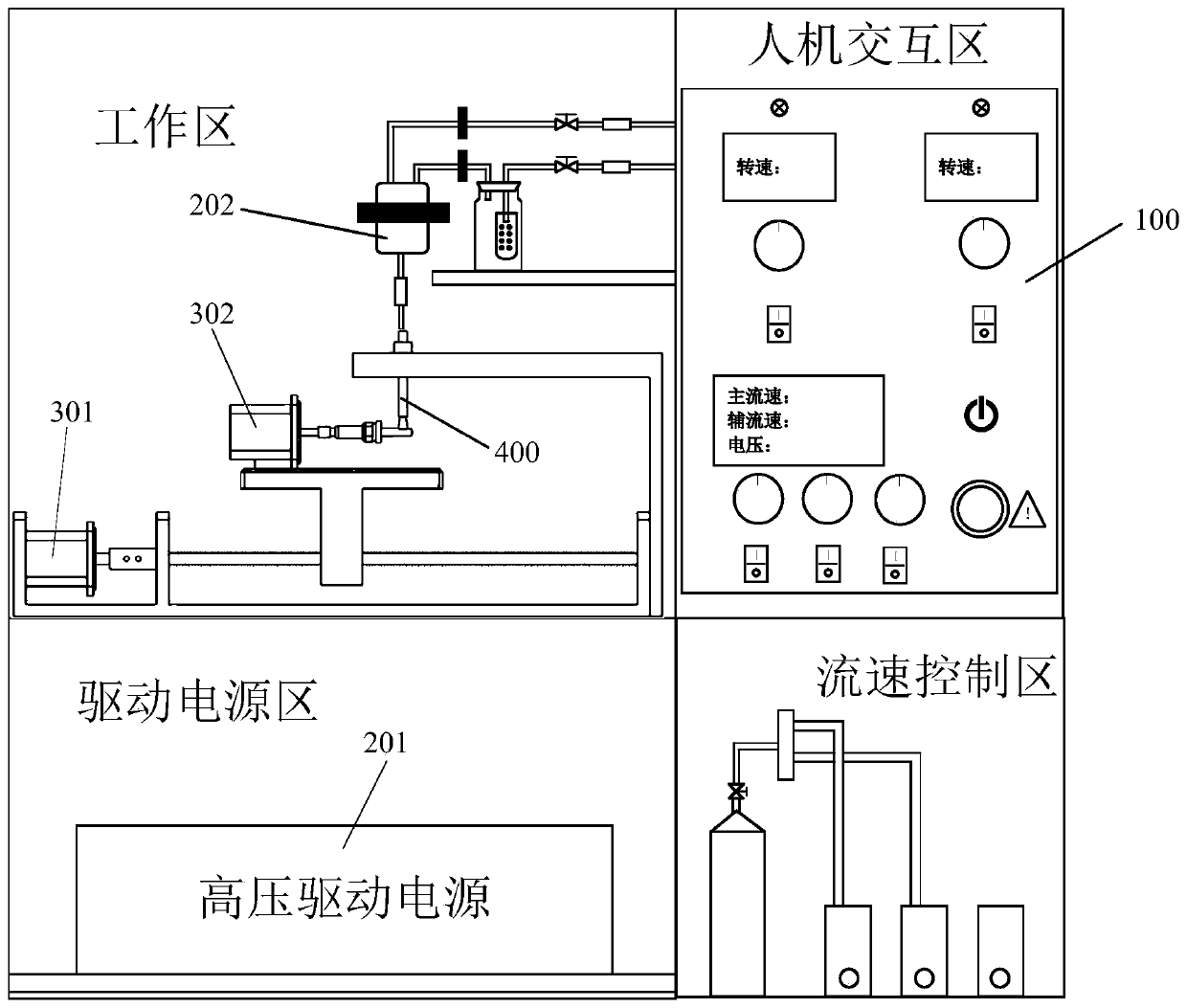

[0037] The invention provides a plasma surface modification device for improving the anti-carbon deposition ability of the spark plug. The device uses active particles generated by jet discharge to treat the surface of the insulating ceramic of the spark plug to change its surface microscopic morphology and chemical composition, thereby achieving two aspects. Effect: On the one hand, it reduces the polarity of the surface to inhibit the formation of carbon deposits; on the other hand, it improves the electrical properties of the surface, reduces the surface resistance, and increases the withstand voltage along the surface. The following will combine image 3 Describe the overall device structure and its operating principle.

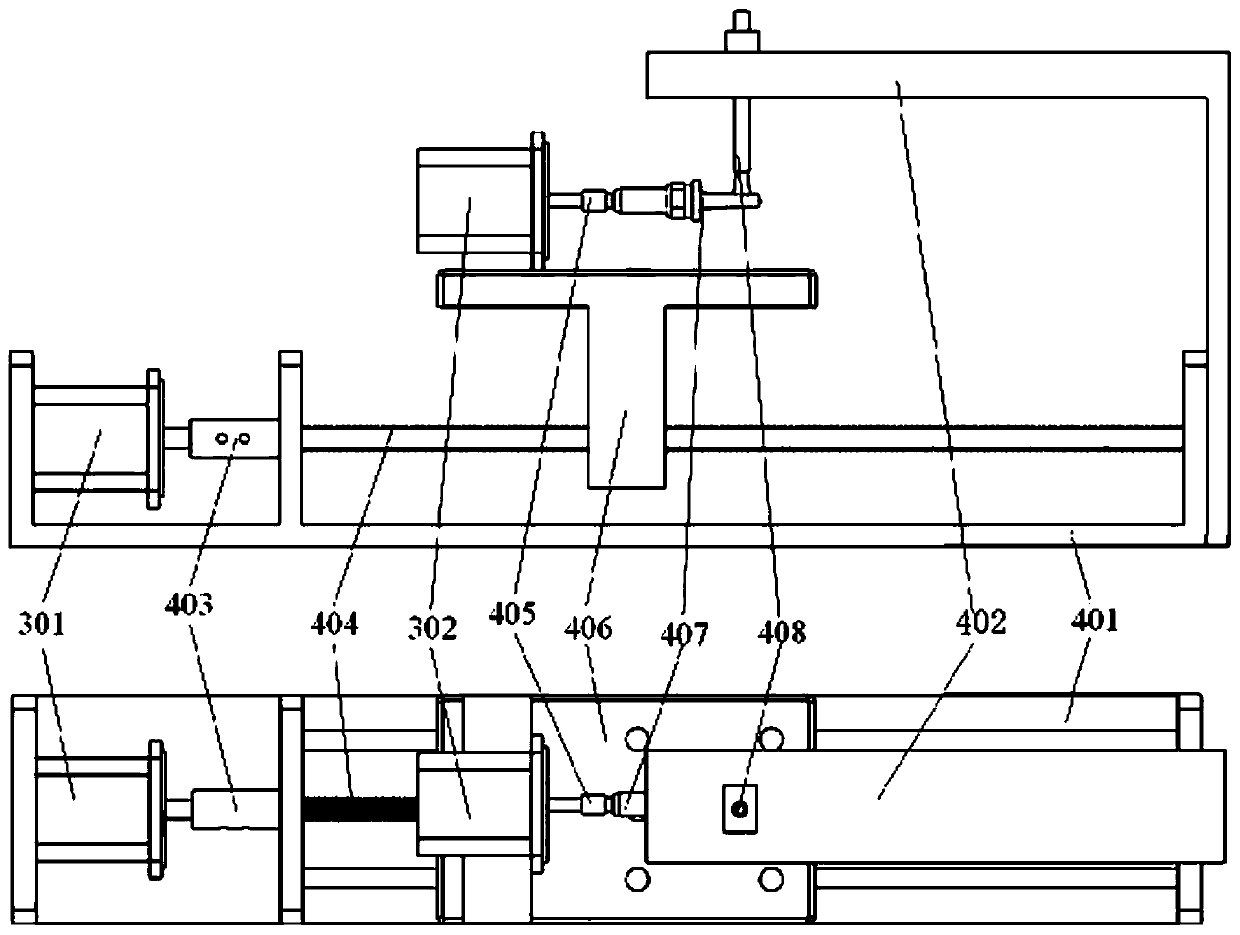

[0038] image 3 A schematic diagram of the overall reactor structure.

[0039] The overall reactor structure 400 includes a stainless steel support base 401, a jet tube clamp 402, a translation screw coupling 403, a translation screw 404, a spark plug c...

Embodiment 2

[0048] The above-mentioned overall plasma coating process will be introduced below, and the specific workflow is as follows: Image 6 shown. First open the gas cylinder, turn on the main flow rate valve-controlled switch 115 and the auxiliary flow rate valve-controlled switch, usually we choose Ar gas as the working gas, add a precursor in the gas washing bottle 2026, usually select a silicon-containing organic liquid compound (such as Hexa base disiloxane HMDSO). When adjusting the flow rate, the adjustment range of the flow rate of the main air path is 0-5L / min, generally controlled at 1L / min, the adjustment range of the flow rate of the auxiliary air path is 0-100mL / min, generally controlled at 20mL / min, the flow rate can be adjusted according to the modification effect Appropriate adjustments. The power supply is pulse-driven power supply, the fixed pulse frequency is 5kHz, the pulse rising and falling edges are 100ns, the pulse width is 800ns, the adjustment amplitude r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com