Complete feed for later fattening of white feather broilers and preparation method and application thereof

A technology of full-price feed and white-feathered broiler chickens, which is applied in the fields of application, animal feed, animal feed, etc., can solve the problems of hard to find breeding workers, many chicken diseases, and complexity, so as to reduce the death rate, reduce the feed-to-meat ratio, and formula reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

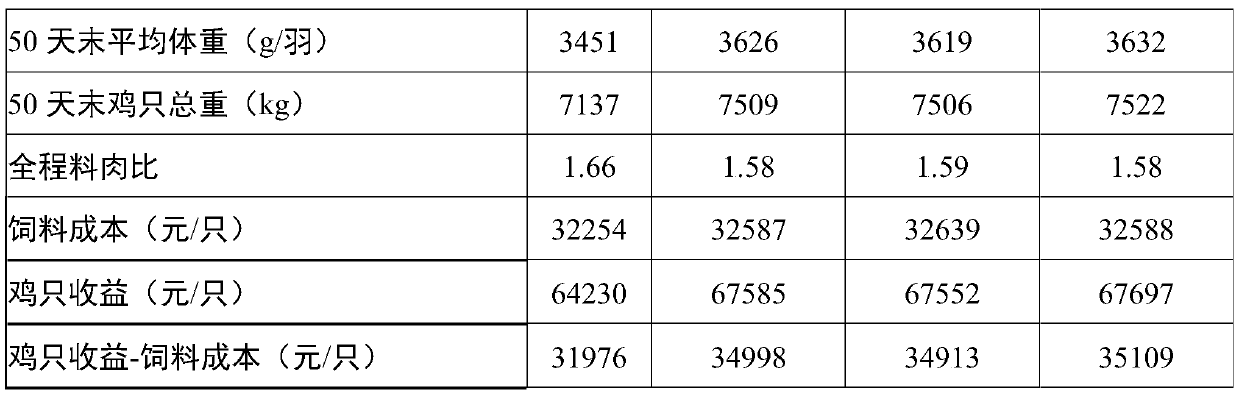

Examples

Embodiment 1

[0028] This embodiment discloses the late fattening complete feed for white feather broilers of the present invention, which contains the following components by weight:

[0029] 52.8 parts of corn, 23.5 parts of soybean meal, 7.0 parts of flour, 7.0 parts of lard, 1.0 part of corn alcohol grains, 4.0 parts of corn gluten meal, 1.38 parts of stone powder, 1.23 parts of calcium hydrogen phosphate, 0.70 parts of lysine, 0.20 parts of methionine, table salt 0.20 part, bentonite 0.32 part, baking soda 0.20 part, multivitamin 0.20 part, threonine 0.19 part, compound trace element 0.17 part, choline chloride 0.06 part, compound enzyme 0.03 part, bile acid 0.03 part, phytase 0.02 part Parts, 0.02 parts of antioxidant.

[0030] Multivitamins are calculated per kilogram, including vitamin A 3500000-5000000IU, vitamin D9000000-1800000IU, vitamin E≥5500mg, vitamin K3≥2400mg, vitamin B1≥580mg, vitamin B2≥20000mg, vitamin B6≥1300mg.

[0031] The compound trace elements are calculated per kilogra...

Embodiment 2

[0038] In this embodiment, a complete feed for white feather broilers in late fattening process includes the following components by weight:

[0039] 49.7 parts of corn, 25.1 parts of soybean meal, 8.0 parts of flour, 8.0 parts of lard, 2.0 parts of corn alcohol grains, 2.0 parts of corn gluten meal, 1.32 parts of stone flour, 1.19 parts of calcium hydrogen phosphate, 0.74 parts of lysine, 0.25 parts of methionine, table salt 0.25 parts, 0.60 parts of bentonite, 0.10 parts of baking soda, 0.17 parts of multivitamins, 0.23 parts of threonine, 0.16 parts of complex trace elements, 0.08 parts of choline chloride, 0.02 parts of complex enzymes, 0.03 parts of bile acids, 0.02 parts of phytase Parts, 0.02 parts of antioxidant.

[0040] Multivitamins are calculated per kilogram, including vitamin A 3500000-5000000IU, vitamin D9000000-1800000IU, vitamin E≥5500mg, vitamin K3≥2400mg, vitamin B1≥580mg, vitamin B2≥20000mg, vitamin B6≥1300mg.

[0041] The compound trace elements are calculated p...

Embodiment 3

[0048] In this embodiment, a complete feed for white feather broilers in late fattening process includes the following components by weight:

[0049] 46.3 parts of corn, 27.1 parts of soybean meal, 9.0 parts of flour, 9.0 parts of lard, 4.0 parts of corn alcohol grains, 1.28 parts of stone powder, 1.07 parts of calcium hydrogen phosphate, 0.48 parts of lysine, 0.20 parts of methionine, 0.30 parts of salt, 0.60 parts of bentonite , 0.2 part of multivitamin, 0.15 part of threonine, 0.15 part of compound trace element, 0.1 part of choline chloride, 0.02 part of compound enzyme, 0.03 part of bile acid, 0.02 part of phytase, 0.02 part of antioxidant.

[0050] Multivitamins are calculated in kilograms, including vitamin A 3500000-5000000IU, vitamin D 9000000-1800000IU, vitamin E≥5500mg, vitamin K3≥2400mg, vitamin B1≥580mg, vitamin B2≥20000mg, vitamin B6≥1300mg.

[0051] The compound trace elements are calculated per kilogram, including selenium 0.08-0.3g, iodine 1.5-3g, copper 5.6-12g, iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com