Production method of low-sodium low-temperature sauced beef

A production method and technology for sauced beef, applied in the production field of low-sodium and low-temperature sauced beef, can solve the problems of heavy external taste, different material and taste, weak taste, etc., and achieve the effects of high yield, good quality and unique flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

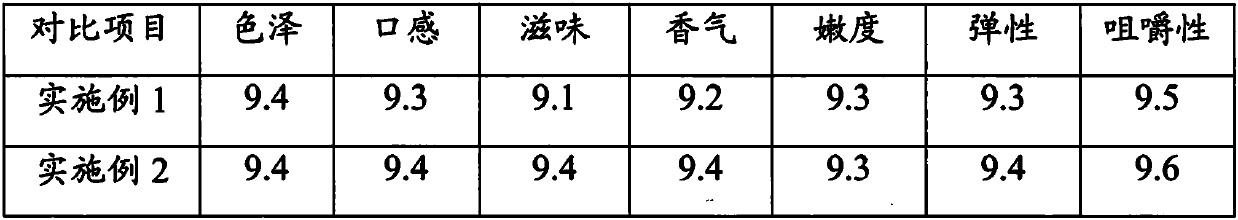

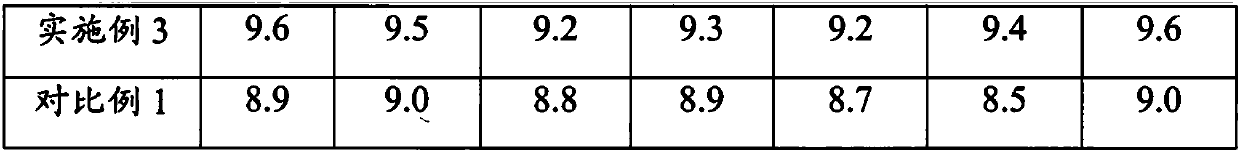

Examples

Embodiment 1

[0032] Present embodiment provides a kind of production method of low-sodium low-temperature beef sauce, comprising the following steps:

[0033] S1. Selection and processing of raw materials: select fresh beef, remove cartilage, lymph, congestion, clean water to decontaminate, drain the water, poke some fine holes on the surface of the beef, beat and knead with the back of a knife, and cut into pieces;

[0034] S2. Tumbling and marinating:

[0035] The preparation of marinating solution: take by weighing 2.0% of low-sodium compound salt, 0.1% of baking soda, 1.6% of white sugar, 1.2% of cornstarch, 0.5% of green onion and ginger juice, 14% of ice water according to the mass percentage of beef, mix evenly, It is prepared into a pickling solution, wherein the mass ratio of sodium chloride, potassium chloride and calcium chloride in the low-sodium compound salt is 4:4:1;

[0036] Mix the marinade prepared above with the beef treated in step S1 to marinate evenly. Under the cond...

Embodiment 2

[0044] Present embodiment provides a kind of production method of low-sodium low-temperature beef sauce, comprising the following steps:

[0045] S1. Selection and processing of raw materials: select fresh beef, remove cartilage, lymph, congestion, clean water to decontaminate, drain water, poke some fine holes on the surface of beef, beat and knead with the back of a knife, and cut into pieces;

[0046] S2. Tumbling and marinating:

[0047]The preparation of marinating solution: take by weighing 2.2% of low-sodium compound salt, 0.3% of baking soda, 1.6% of white sugar, 0.8% of cornstarch, 0.2% of green onion and ginger juice, 16% of ice water according to the mass percentage of beef, mix well, It is prepared into a pickling solution, wherein the mass ratio of sodium chloride, potassium chloride and calcium chloride in the low-sodium compound salt is 5:3:1;

[0048] Mix the marinating solution prepared above with the beef treated in step S1 and marinate evenly. Under the con...

Embodiment 3

[0056] Present embodiment provides a kind of production method of low-sodium low-temperature beef sauce, comprising the following steps:

[0057] S1. Selection and processing of raw materials: select fresh beef, remove cartilage, lymph, congestion, clean water to decontaminate, drain water, poke some fine holes on the surface of beef, beat and knead with the back of a knife, and cut into pieces;

[0058] S2. Tumbling and marinating:

[0059] The preparation of marinating solution: take by weighing 2.1% of low-sodium compound salt, 0.2% of baking soda, 1.5% of white sugar, 1.0% of cornstarch, 0.4% of green onion and ginger juice, 15% of ice water according to the mass percentage of beef, mix evenly, It is prepared into a pickling solution, wherein the mass ratio of sodium chloride, potassium chloride and calcium chloride in the low-sodium compound salt is 4:4:0.5;

[0060] Mix the marinade prepared above with the beef treated in step S1 to marinate evenly. Under the conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com