Metal powder core welding wire for atmosphere corrosion resistant fire-resistant steel

A kind of atmospheric corrosion resistance, metal powder core technology, used in metal processing equipment, welding media, welding equipment and other directions, can solve the problems of strength and stiffness decline, causing disasters, collapse of steel structure buildings, etc., to achieve high low temperature impact toughness, The effect of high temperature resistance ability and atmospheric corrosion resistance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

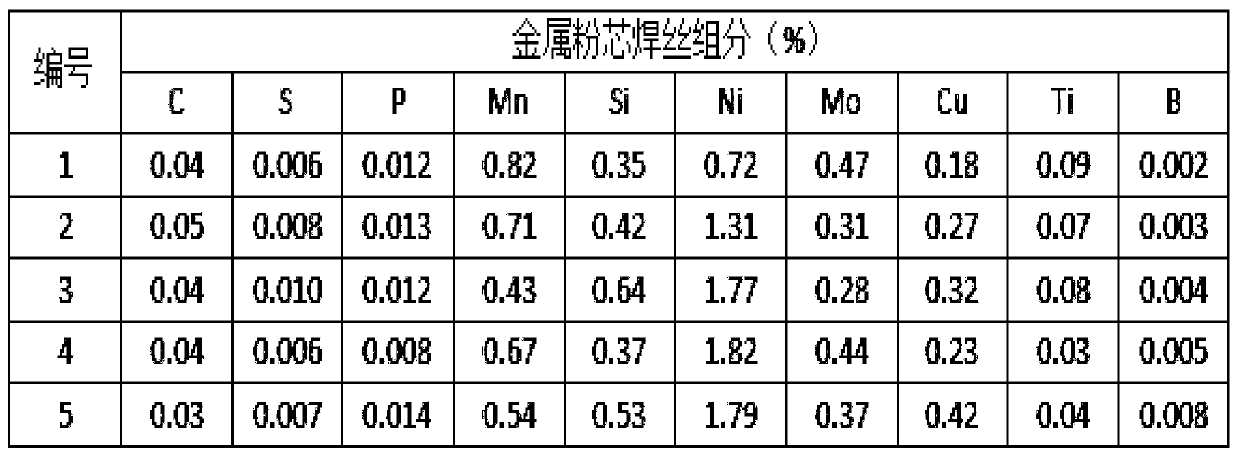

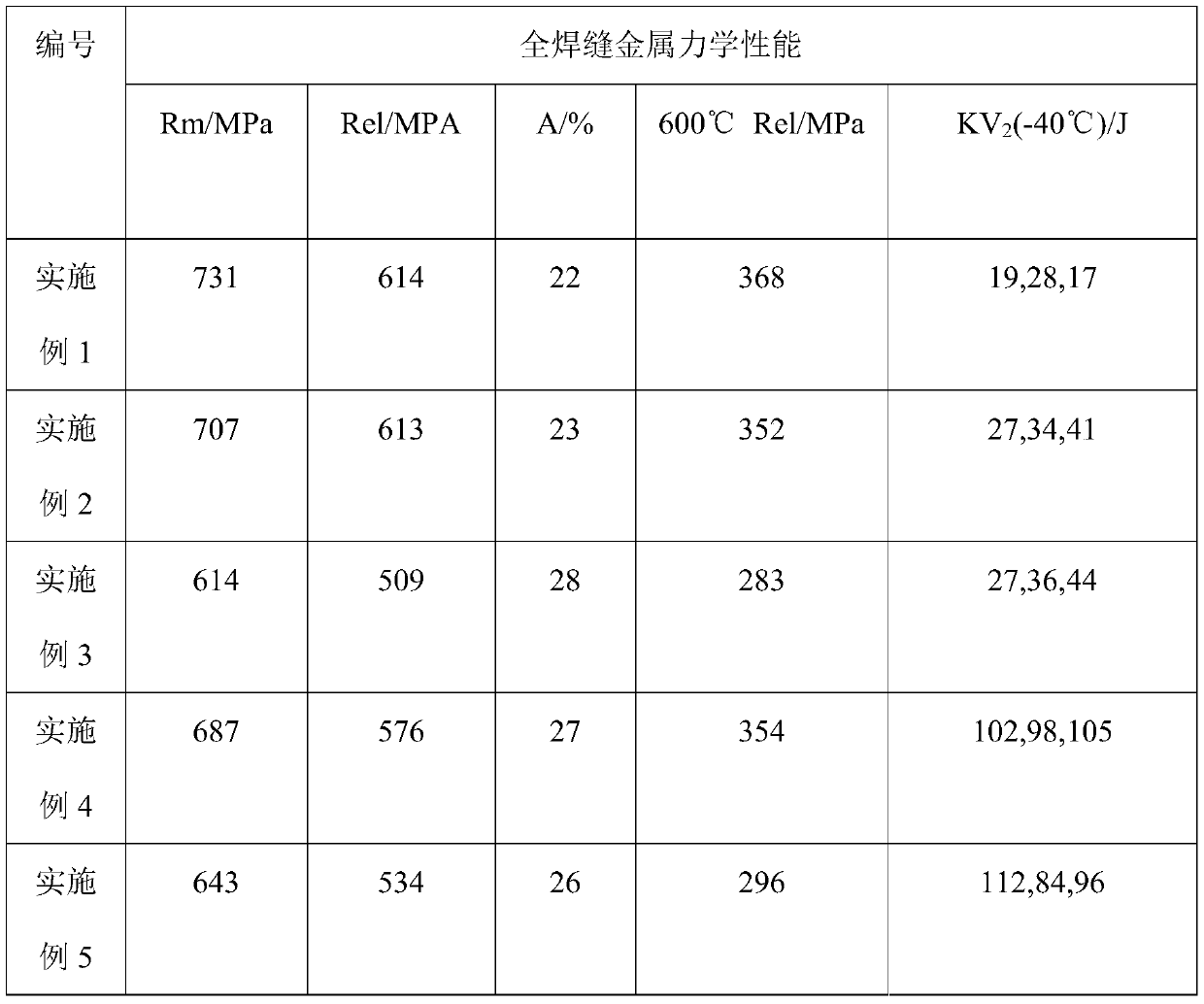

Embodiment 1

[0033] A metal powder cored welding wire for atmospheric corrosion resistant refractory steel, its chemical composition includes: C: 0.04%, Mn: 0.82%, Si: 0.35%, Ni: 0.72%, Mo: 0.47, Cu: 0.18 %, B: 0.002%, Ti: 0.09%, S: 0.006%, P: 0.012%, and the balance of Fe.

[0034] A metal powder-cored welding wire for atmospheric corrosion-resistant refractory steel, the manufacturing method of which specifically includes the following steps:

[0035] S1. First, use desulfurized molten iron to control the sulfur content of the molten iron in the furnace, and then adopt the method of converter steelmaking, select raw materials with low S and P content, and adopt the top-bottom composite blowing process to convert the C, S and P at the end of the smelting controlled at a low level;

[0036] S2. After deoxidation and alloying, the molten steel whose composition meets the requirements is smelted by the out-of-furnace refining process of the ladle refining furnace. The molten steel is fully ...

Embodiment 2

[0039] A metal powder cored welding wire for atmospheric corrosion resistant refractory steel, its chemical composition includes: C: 0.05%, Mn: 0.71%, Si: 0.42%, Ni: 1.31%, Mo: 0.31, Cu: 0.27 %, B: 0.003%, Ti: 0.07%, S: 0.008%, P: 0.013%, and the balance of Fe.

[0040] A metal powder-cored welding wire for atmospheric corrosion-resistant refractory steel, the manufacturing method of which specifically includes the following steps:

[0041] S1. First, use desulfurized molten iron to control the sulfur content of the molten iron in the furnace, and then adopt the method of converter steelmaking, select raw materials with low S and P content, and adopt the top-bottom composite blowing process to convert the C, S and P at the end of the smelting controlled at a low level;

[0042] S2. After deoxidation and alloying, the molten steel whose composition meets the requirements is smelted by the out-of-furnace refining process of the ladle refining furnace. The molten steel is fully ...

Embodiment 3

[0045] A metal powder cored welding wire for atmospheric corrosion-resistant refractory steel, its chemical composition includes: C: 0.04%, Mn: 0.43%, Si: 0.64%, Ni: 1.77%, Mo: 0.28%, Cu: 0.32%, B: 0.004%, Ti: 0.08%, S: 0.01%, P: 0.012%, and the balance of Fe.

[0046] A metal powder-cored welding wire for atmospheric corrosion-resistant refractory steel, the manufacturing method of which specifically includes the following steps:

[0047] S1. First, use desulfurized molten iron to control the sulfur content of the molten iron in the furnace, and then adopt the method of converter steelmaking, select raw materials with low S and P content, and adopt the top-bottom composite blowing process to convert the C, S and P at the end of the smelting controlled at a low level;

[0048] S2. After deoxidation and alloying, the molten steel whose composition meets the requirements is smelted by the out-of-furnace refining process of the ladle refining furnace. The molten steel is fully p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com