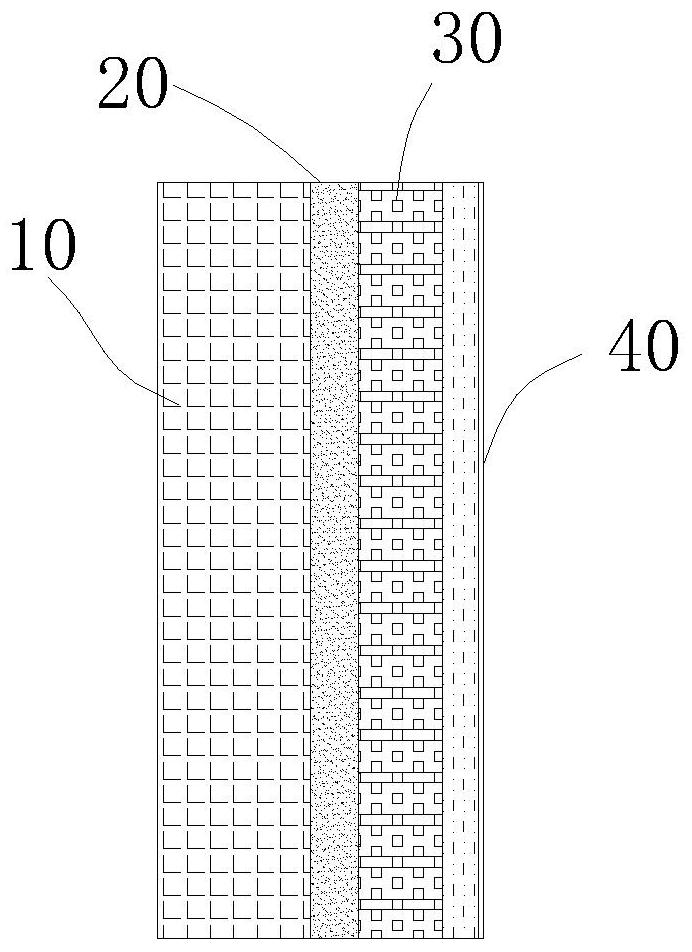

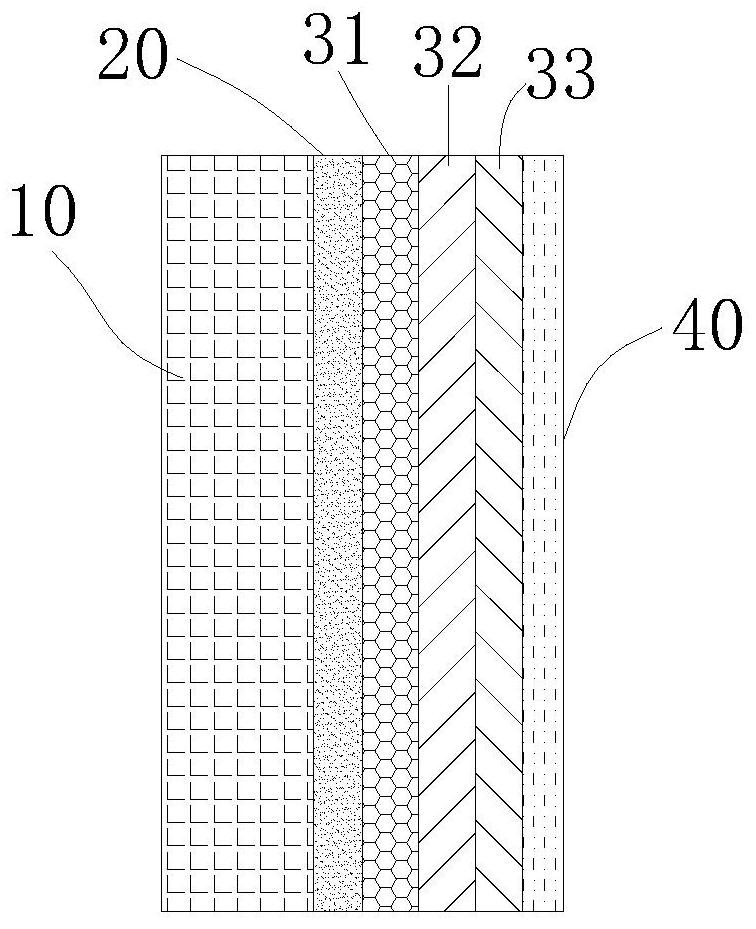

Construction method of composite coating and wall

A composite coating and aggregate technology, applied in the field of composite coating and wall construction, can solve the problems of top paint pollution, labor cost increase, wall hollowing, etc., to improve the degree of gelation and stability, and reduce construction roads Number, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

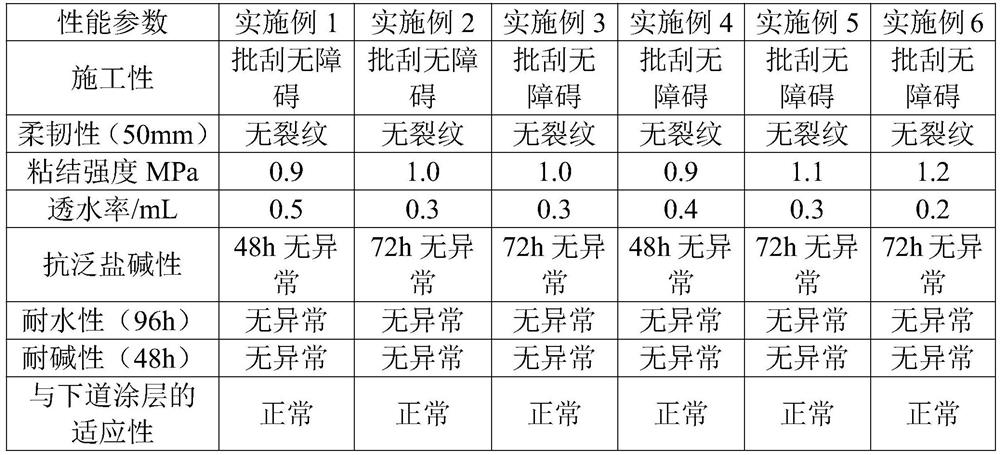

Examples

Embodiment 1

[0064] In terms of mass percentage, the composition of the composite coating in this example includes: 10% water, 0.3% hydroxyethyl cellulose (30,000 viscosity) HD-30000; 0.1% co-dispersant APM-95, 0.2% Wetting and dispersing agents PE-100 and 5027, 0.15% defoamer NXZ, 0.5% titanium dioxide R996, 10% acrylate copolymer emulsion (Tg is 25℃, latex particle size is 50μm~120μm), 5% of acrylate elastic emulsion (Tg is -5℃, particle size of latex is 80μm~200μm), 5% of silica sol CH-83, 0.5% of film-forming aid dodecyl alcohol ester, 0.5% of Propylene glycol, 0.15% bactericidal preservatives WL-3 and WL-86, 30% 50-60 mesh round sand, 37% 150-mesh quartz sand, 0.4% thickener DR-72, 0.2% water-based color paste.

[0065] The preparation method of the composite coating is as follows: adding hydroxyethyl cellulose in water, adding co-dispersant dropwise after complete dispersion, then adding wetting and dispersing agent, defoamer, titanium dioxide, acrylate copolymer emulsion and acryla...

Embodiment 2

[0068] In terms of mass percentage, the composition of the composite coating in this embodiment includes: 10% water, 0.3% hydroxyethyl cellulose (30,000 viscosity) HBR-250; 0.1% co-dispersant APM-95, 0.2% Wetting and dispersing agents PE-100 and 5027, 0.15% defoamer MX-68, 0.5% titanium dioxide R996, 10% acrylate copolymer emulsion (Tg is 25 ℃, the particle size of the latex is 50μm ~ 120μm ), 5% acrylate elastic latex (Tg is -5°C, particle size of latex is 80μm~200μm), 5% silica sol BS620, 0.5% film-forming aid dodecyl ester, 0.5% Propylene glycol, 0.15% bactericidal preservatives WL-3 and WL-86, 30% 80-120-mesh round sand, 37% 200-mesh ground calcium carbonate, 0.4% thickener DR-72 and D- 305, 0.2% water-based color paste.

[0069] The preparation method of the composite coating is as follows: adding hydroxyethyl cellulose in water, adding co-dispersant dropwise after complete dispersion, then adding wetting and dispersing agent, defoamer, titanium dioxide, acrylate copolym...

Embodiment 3

[0072] In terms of mass percentage, the composition of the composite coating in this embodiment includes: 10% water, 0.3% hydroxyethyl cellulose (30,000 viscosity) HBR-250; 0.1% co-dispersant APM-95, 0.2% Wetting and dispersing agents PE-100 and 5027, 0.15% antifoaming agent SN-345, 0.5% titanium dioxide R-706, 10% acrylate copolymer emulsion (Tg is 25℃, particle size of latex is 50μm ~120μm), 5% acrylate elastic emulsion (Tg is -5℃, particle size of latex is 80μm~200μm), 5% silica sol CH-83, 0.5% film-forming aid dodecyl ester , 0.5% propylene glycol, 0.15% bactericidal preservatives WL-3 and WL-86, 40% 150 mesh quartz sand, 12% 200 mesh quartz sand, 15% 200 mesh heavy calcium carbonate, 0.4% increase Thickeners DR-72 and D-305, 0.2% aqueous color paste.

[0073] The preparation method of the composite coating is as follows: adding hydroxyethyl cellulose in water, adding co-dispersant dropwise after complete dispersion, then adding wetting and dispersing agent, defoamer, tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com