Polyamide 5X resin as well as preparation method and application thereof

A polyamide resin and polyamide technology, applied in the field of polyamide materials, can solve the problems of broken ends, no observed melting double peaks, uneven deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095](1) Under nitrogen conditions, mix 1,5-pentanediamine, adipic acid and water evenly to obtain 80% polyamide salt solution, wherein the salt weighs 20kg; 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05):1, and the pH value of the polyamide salt solution is 7.90 when the concentration of the polyamide salt solution is 10wt.%. The percentage is the mass percentage of the polyamide salt solution.

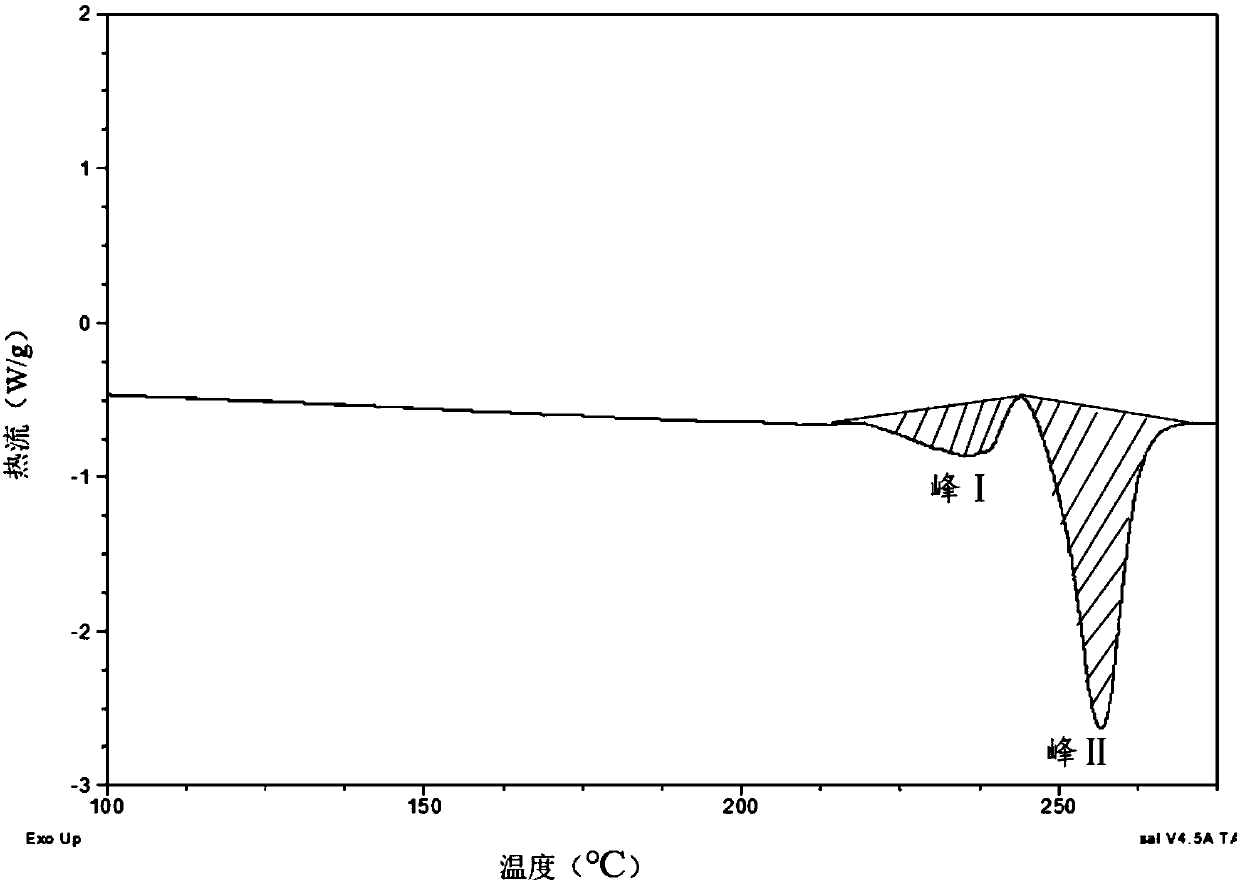

[0096] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.7Mpa, exhaust, keep the pressure, the temperature of the reaction system at the end of the pressure keeping is 245°C, and then reduce the pressure to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), the temperature of the reaction system after depressurization is 262°C, the vacuum is maintained at -0.01Mpa, the vacuum time is 20min, the temperature after vacuum is 268°C, and a polyamide melt is obtained.

[0097] (3) Resin obtained by pelletizing

[...

Embodiment 2

[0111] (1) Under nitrogen conditions, mix 1,5-pentanediamine, adipic acid and water evenly to obtain 80% polyamide salt solution, wherein the salt weighs 20kg; 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05):1, and the pH value of the polyamide salt solution is 7.91 when the concentration of the polyamide salt solution is 10wt.%. The percentage is the mass percentage of the polyamide salt solution.

[0112] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.7Mpa, exhaust, keep the pressure, the temperature of the reaction system at the end of the pressure keeping is 244°C, and then reduce the pressure to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), the temperature of the reaction system was 264°C after the depressurization was completed, the vacuum was maintained at -0.01Mpa, the vacuum time was 21min, the temperature after vacuum was 269°C, and a polyamide melt was obtained.

[0113] (3) Resin obta...

Embodiment 3

[0118] (1) Under nitrogen conditions, mix 1,5-pentanediamine, adipic acid and water evenly to obtain 80% polyamide salt solution, wherein the salt weighs 20kg; 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05):1, and the pH value of the polyamide salt solution is 7.89 when the concentration of the polyamide salt solution is 10wt.%. The percentage is the mass percentage of the polyamide salt solution.

[0119] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.7Mpa, exhaust, keep the pressure, the temperature of the reaction system at the end of the pressure keeping is 244°C, and then reduce the pressure to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), the temperature of the reaction system was 264°C after the depressurization, the vacuum was maintained at -0.01Mpa, the vacuum time was 22min, the temperature after vacuum was 269°C, and a polyamide melt was obtained.

[0120] (3) Resin obtained by pellet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com