A moving bed discharge device

A moving bed and material rack technology, which is applied in the improvement of process efficiency, recycling technology and other directions, can solve the problems of slag particles reheating and bonding, unsatisfactory slag discharge effect, and low heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

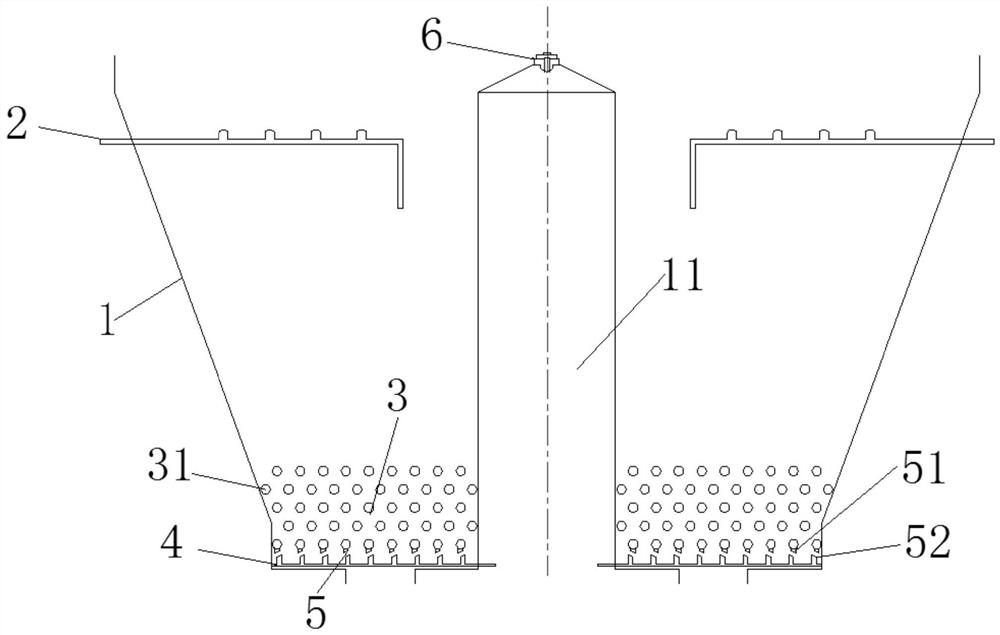

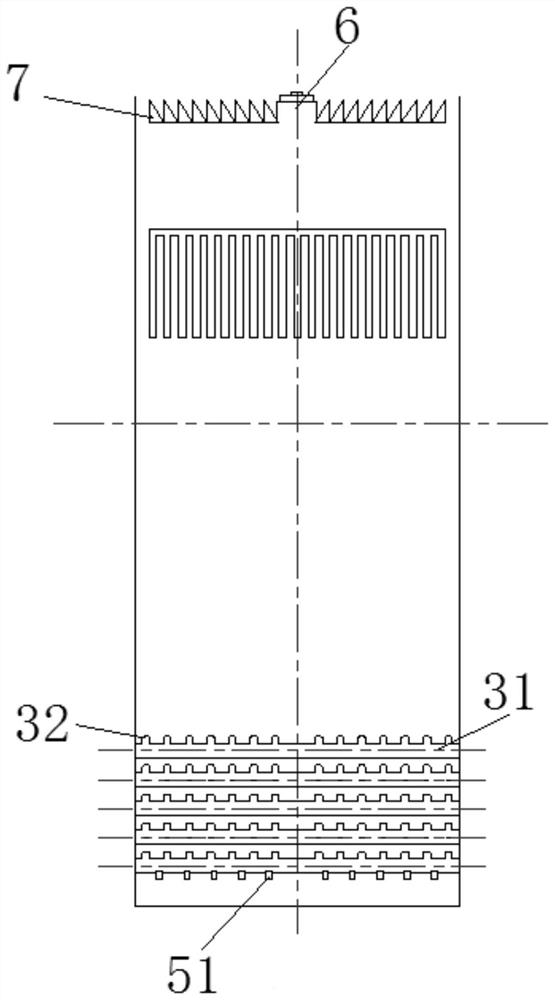

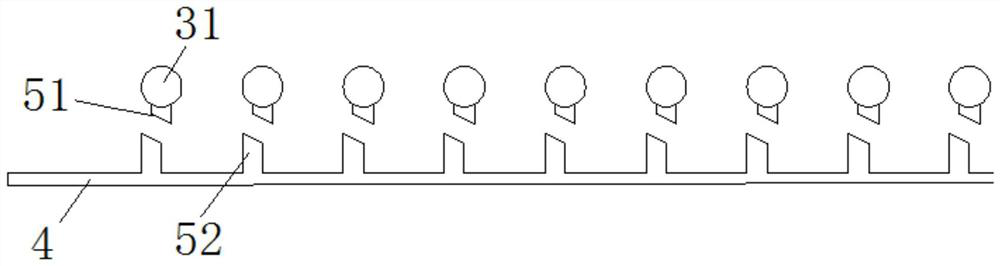

[0039]The liquid slag discharged from the blast furnace first passes through the liquid slag buffer and flow measurement and control devices (slag ladle, combustion device, flue gas pipeline, flow measurement and control module and flow control device; the combustion device is set on the top of the slag ladle and connected with the slag The inside of the bag is connected; the side of the slag bag is connected with a flow measurement and control module, and the slag bag is connected to the flow measurement and control module through the flue gas pipeline; the flow measurement and control module is equipped with a flow control device). Then the liquid slag enters into the slag pipe (the slag pipe fixing device with preheating and cooling functions is provided to solve the problem of easy blockage and breakage of the slag pipe during the centrifugal granulation of liquid slag, and high-temperature corrosion of the slag pipe fixing device. serious issues). The liquid slag is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com