Preparation method of normal-temperature iron oxide desulfurizing agent based on manganese metal liquid preparation

An iron oxide desulfurizer and metal manganese technology, which is applied to the improvement of process efficiency, photography technology, instruments and other directions, can solve the problems of increasing the amount of slag, unfavorable comprehensive utilization of electrolytic manganese slag, etc., and achieves a simple production process and achieves weight reduction. The effect of reducing production costs and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

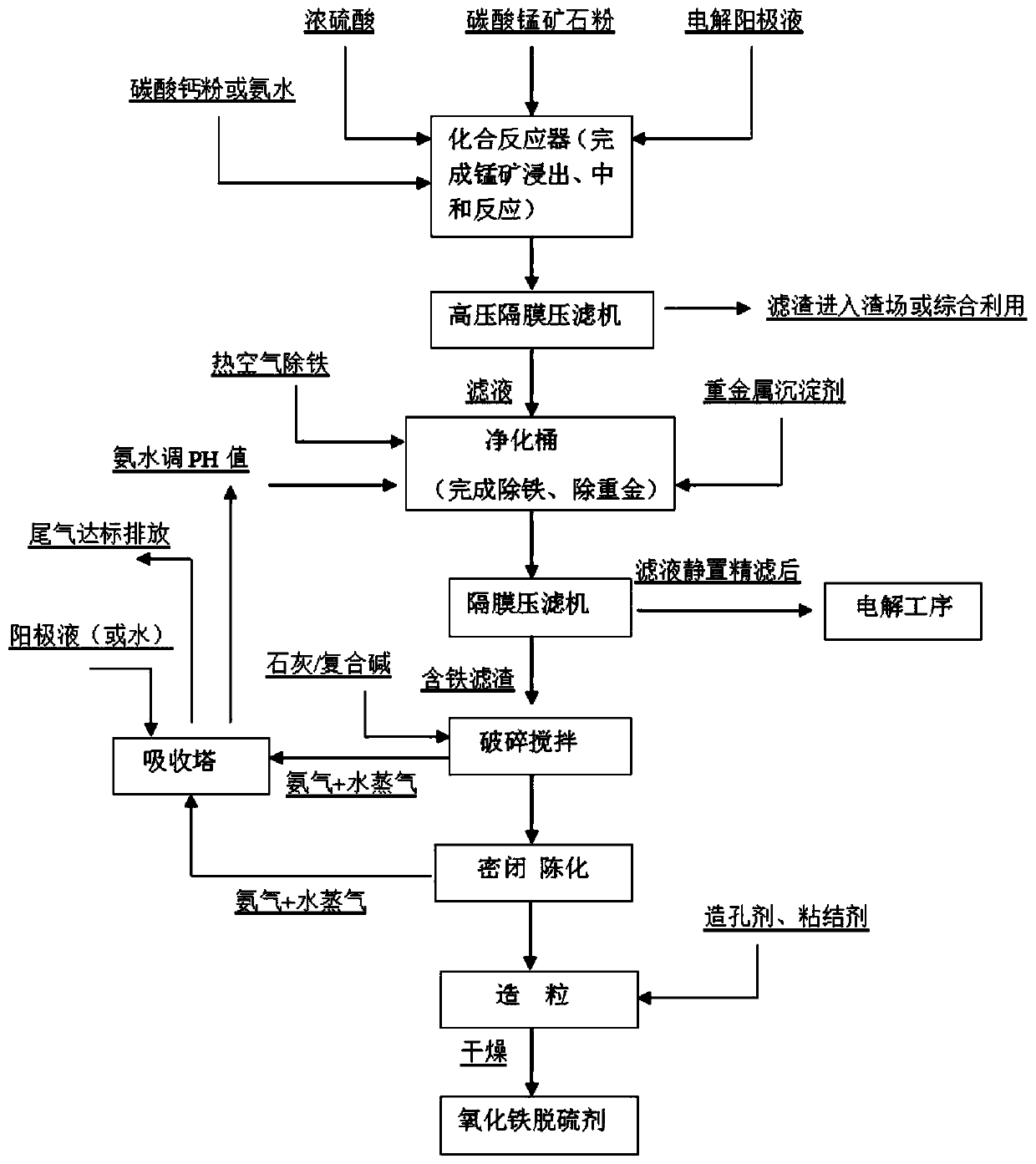

[0028] Embodiment: a kind of preparation method of the normal temperature iron oxide desulfurizer based on metal manganese liquid, such as figure 1 As shown, it specifically includes the following steps:

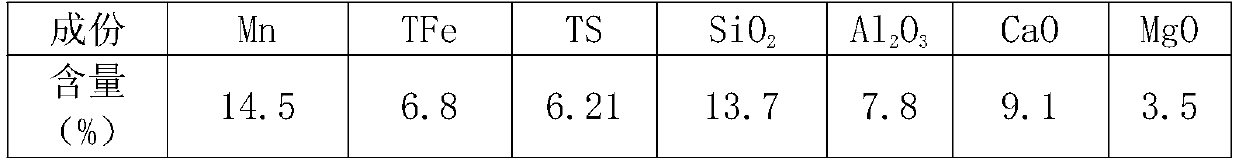

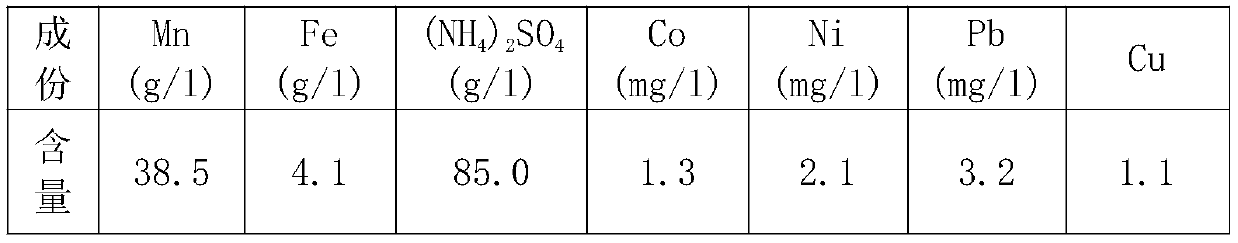

[0029] S1. Grind the manganese carbonate ore into manganese carbonate ore powder and put it into the compounding reactor, and according to the acid consumption of the manganese carbonate ore powder, add the corresponding proportion of concentrated sulfuric acid and the electrolytic anolyte returned by electrolysis into the compounding reactor to carry out the compounding reaction After 3-4 hours, the pulp is prepared, and then the residual acid in the pulp is detected. According to the total amount of residual acid in the pulp, a neutralizing agent is added to the compound reactor for neutralization reaction, and the pH value of the pulp is neutralized to 5.0-5.5 within range.

[0030] S2. Use a high-pressure diaphragm filter press to conduct the first solid-liquid separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com