High-performance 82B wire rod steel and production method thereof

A production method and high-performance technology, applied in the field of smelting, can solve problems such as a large proportion of broken wires, limited adjustment range of process parameters, and prone to broken wires, so as to solve aging problems, improve product quality, and reduce broken wires rate effect

Inactive Publication Date: 2020-04-21

WUHU XINXING DUCTILE IRON PIPES

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the special characteristics of 82B high carbon steel, its strength and hardness are high, which makes it prone to broken wires during processing

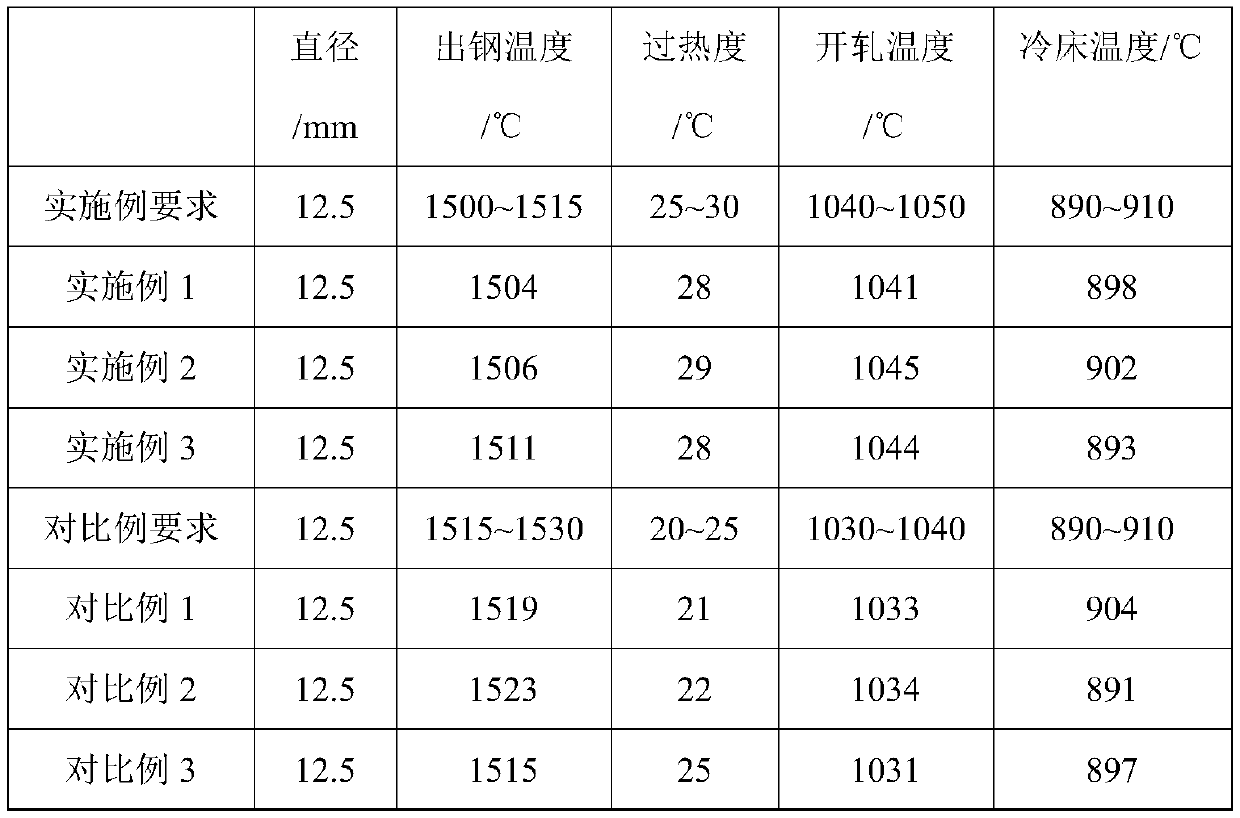

[0004] At present, the conventional process mainly reduces the broken wire rate by adjusting the parameters of steelmaking and steel rolling production. In steelmaking production, it mainly reduces the central carbon segregation by reducing superheat, increasing cooling intensity and electric stirring parameters. In steel rolling production, it mainly uses The cooling rate is controlled by controlling the opening of the fan, the insulation cover, and the speed of the roller table. Through the above-mentioned process adjustments, the broken wire rate of 82B has decreased to a certain extent. However, due to the limited adjustment range of process parameters, the broken wire rate still accounts for a large proportion. It is still an urgent problem to be solved by major domestic steel mills

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1- Embodiment 3

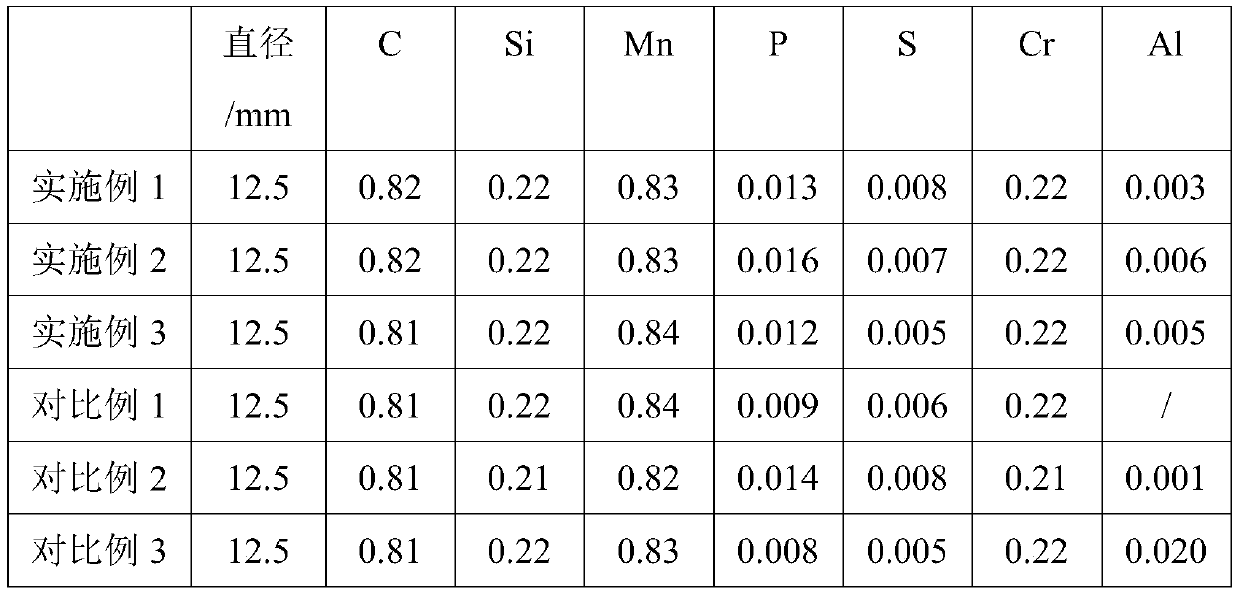

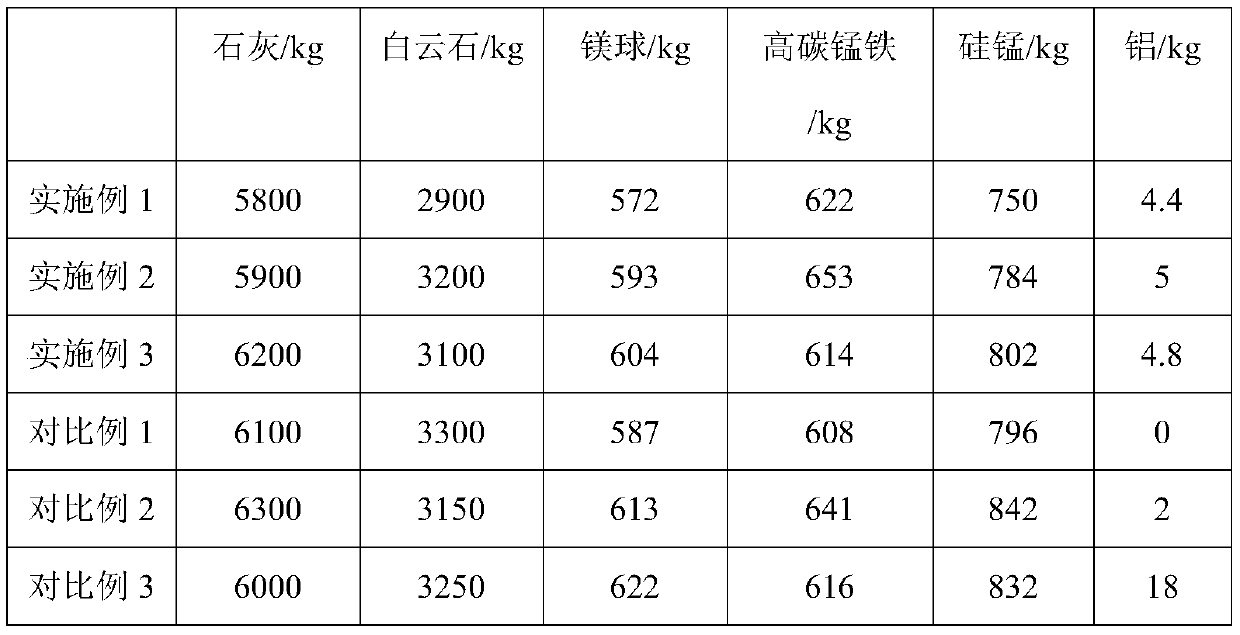

[0027] A high-performance 82B wire rod steel, including the following components by mass percentage: see Table 1 below, and the balance is Fe and unavoidable impurities.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides high-performance 82B wire rod steel and a production method thereof. The steel comprises the following components in percentage by mass: 0.80%-0.82% of C, 0.20%-0.25% of Si, 0.82%-0.87% of Mn, 0.20%-0.30% of Cr, 0.003%-0.010% of Al, P less than or equal to 0.018% of P, S less than or equal to 0.010%, and the balance of Fe and inevitable impurities. Compared with the prior art, micro-aluminum is added into molten steel behind a converter, and the subsequent LF furnace, continuous casting and rolling processes are combined, so that the performance of the steel is improved,the aging problem is solved, the wire breakage rate in the 82B wire rod steel drawing process is reduced, the product quality is improved, and huge benefits are brought to enterprises.

Description

technical field [0001] The invention belongs to the field of smelting, and in particular relates to a high-performance 82B wire rod steel and a production method thereof. Background technique [0002] High-carbon steel SWRH82B wire rod steel is the raw material for the production of prestressed steel strand steel. It is mainly used in bridges, houses, roads and other fields. It has a large annual demand and is currently the mainstream product of many domestic steel mills. [0003] However, 82B wire rod steel needs to go through multiple drawing and twisting to obtain a certain specification of steel strand steel. In the process of processing, 82B wire rod steel needs to have sufficient strength, area shrinkage and good drawing performance. In order to avoid the occurrence of brittle fracture problems. However, due to the special characteristics of 82B high-carbon steel, its high strength and hardness make it prone to wire breakage during processing. [0004] At present, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/18C22C33/04C21C7/00C21C7/076B21B1/46

CPCB21B1/46C21C7/0006C21C7/076C22C33/04C22C38/02C22C38/04C22C38/06C22C38/18Y02P10/20

Inventor 陈永峰左小坦赵立王东兴陶群南张洪彪黄雁杨伟勇

Owner WUHU XINXING DUCTILE IRON PIPES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com