Preparation method of multicomponent comfortable elastic antistatic functional warp-knitted fabric

An antistatic, multi-component technology, applied in conductive/antistatic filament manufacturing, warp knitting, single-component polyester rayon, etc. Defects, warp knitted fabrics feel hard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

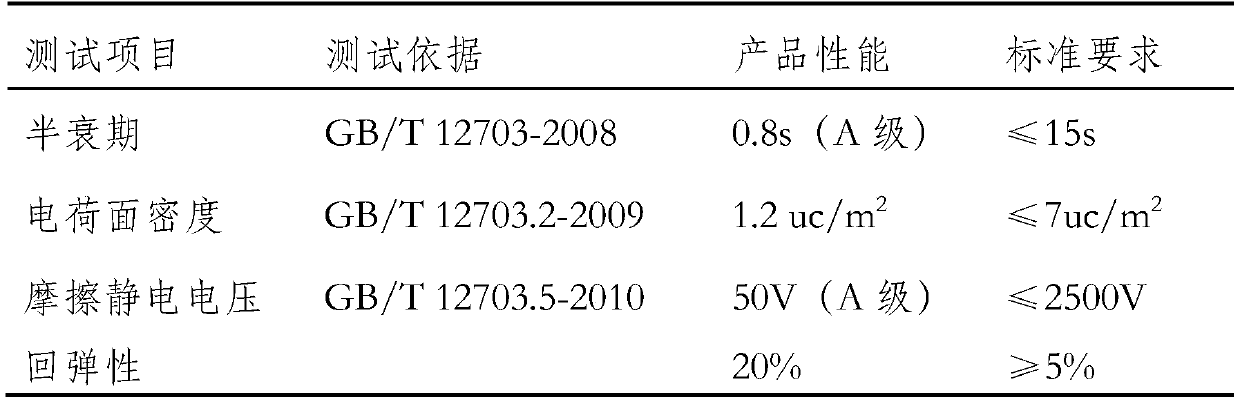

Embodiment 1

[0024] According to parts by weight, 2 parts of nitrogen-doped titanium dioxide and 3 parts of conductive tin oxide are compounded to obtain antistatic functional powder, and the particle size is controlled to be 80-120 nm. Mix the antistatic functional powder, polyurethane and N,N-dimethylformamide, and ultrasonically stir (500rmp, 15min) to prepare a finishing solution. Put ordinary polyester 75 / 144DTY in the finishing solution for 20min, after After drying, wash with softener (softener is a common commercial product, including hydrophilic softener and water-repellent softener), and dry (90°C-100°C) to obtain antistatic polyester fiber.

[0025] 80 parts by weight of antistatic polyester 75 / 72DTY and 20 parts by weight of ordinary polyester 75 / 144DTY are used as raw materials for the face yarn, the middle yarn is made of 50 / 48DTY PBT / PET bicomponent polyester fiber, and the bottom yarn is made of ordinary polyester 75 / 144FDY , through weaving, shaping, dyeing and finishing, ...

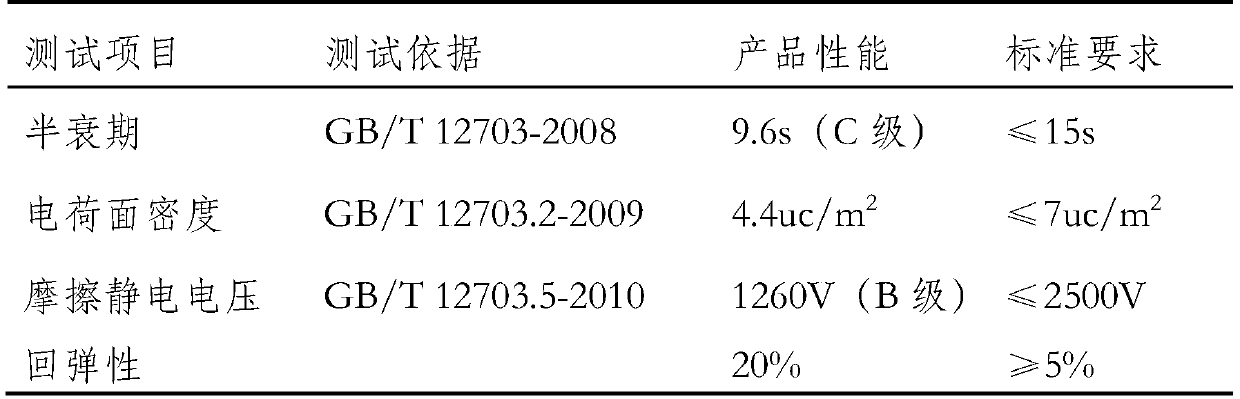

Embodiment 2

[0034] According to parts by weight, 2 parts of nitrogen-doped titanium dioxide and 3 parts of conductive tin oxide are compounded to obtain antistatic functional powder, and the particle size is controlled to be 80-140 nm. Mix the antistatic functional powder, polyurethane and N,N-dimethylformamide, and ultrasonically stir (300rmp, 15min) to prepare a finishing solution. Put ordinary polyester 75 / 144DTY in the finishing solution for 20min. After After drying, add softener and wash with water (softener is a common commercial product, including hydrophilic softener and water-repellent softener), and dry (105°C-110°C) to obtain antistatic polyester fiber.

[0035] 20 parts by weight of antistatic polyester 75 / 72DTY and 80 parts by weight of ordinary polyester 75 / 144DTY are used as raw materials for the face yarn, the middle yarn is made of 50 / 48DTY PBT / PET bicomponent polyester fiber, and the bottom yarn is made of ordinary polyester 75 / 144FDY , through weaving, shaping, dyeing ...

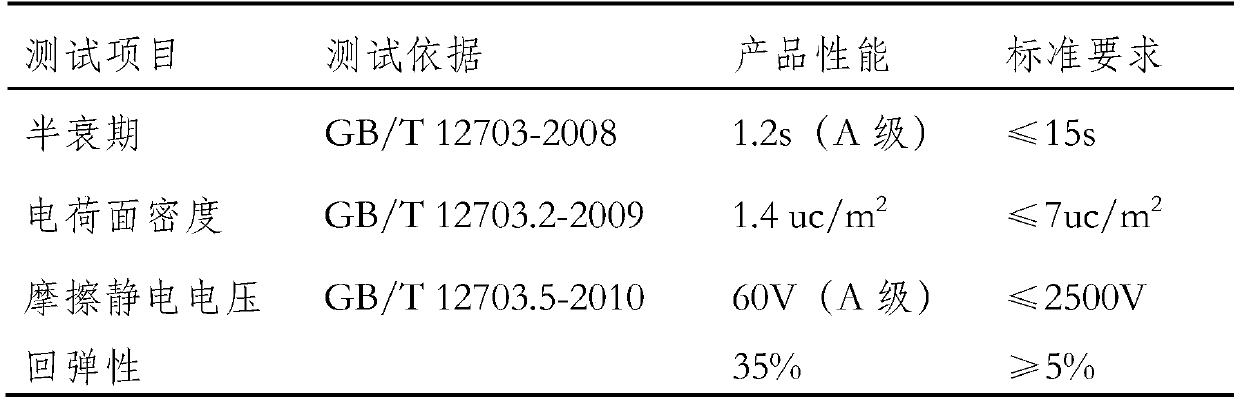

Embodiment 3

[0044] According to parts by weight, 5 parts of nitrogen-doped titanium dioxide and 5 parts of conductive tin oxide are compounded to obtain antistatic functional powder, and the particle size is controlled to be 80-120 nm. Mix the antistatic functional powder, polyurethane and N,N-dimethylformamide, and ultrasonically stir (500rmp, 15min) to prepare a finishing solution. Put ordinary polyester 75 / 144DTY in the finishing solution for 20min, after After drying, add softener and wash with water (softener is a common commercial product, including hydrophilic softener and water-repellent softener), and dry (95°C-105°C) to obtain antistatic polyester fiber.

[0045] 50 parts by weight of antistatic polyester 75 / 72DTY and 50 parts by weight of ordinary polyester 75 / 144DTY are used as raw materials for the face yarn, the middle yarn is made of 50 / 48DTY PBT / PET bicomponent polyester fiber, and the bottom yarn is made of ordinary polyester 75 / 144FDY , through weaving, shaping, dyeing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com