Railway sewage suction truck side suction working device and operation method thereof

A technology of working device and sewage suction vehicle, applied in cleaning methods, track cleaning, construction, etc., can solve the problems of inability to real-time output of dirt, less dirt storage, low efficiency, etc., to achieve environmental protection and decontamination operations and solve efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

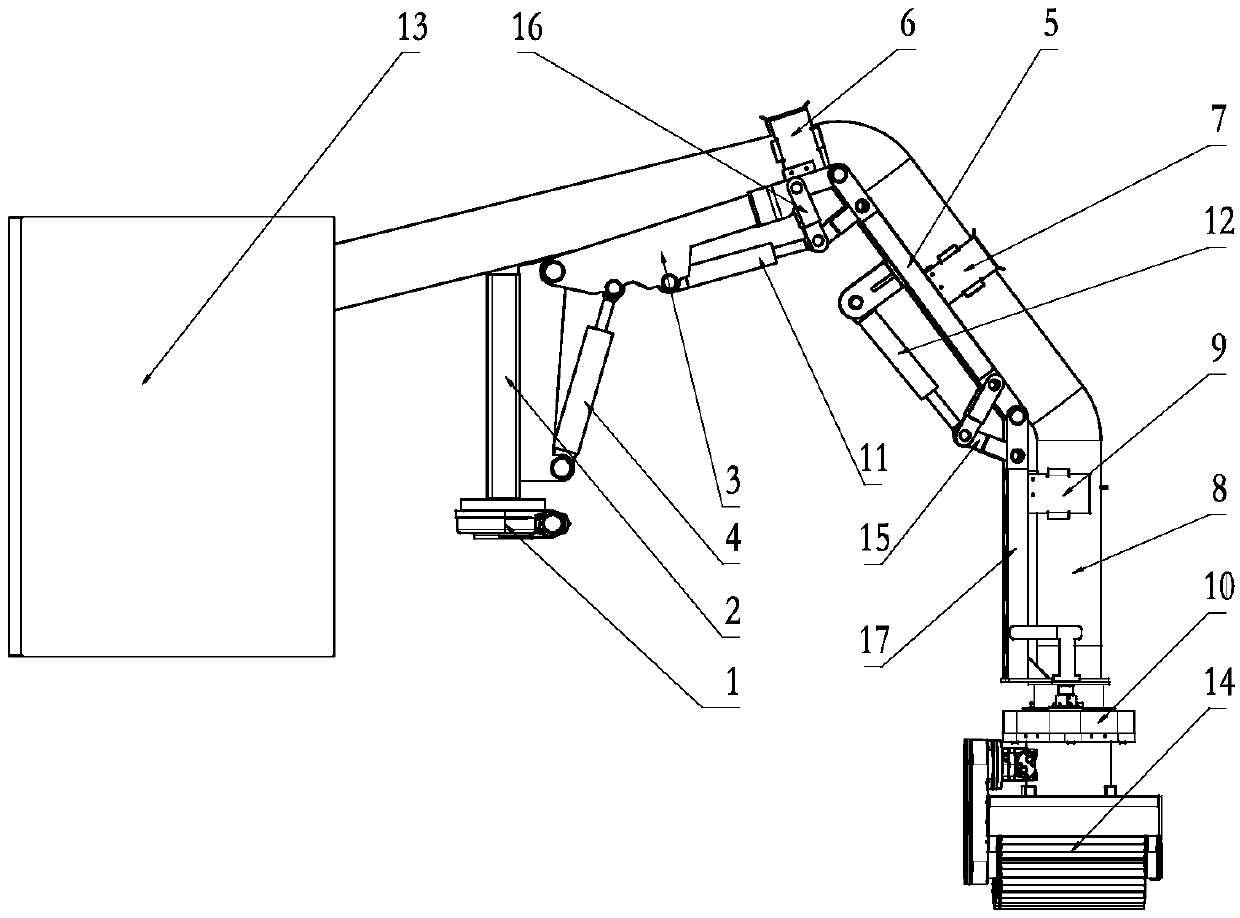

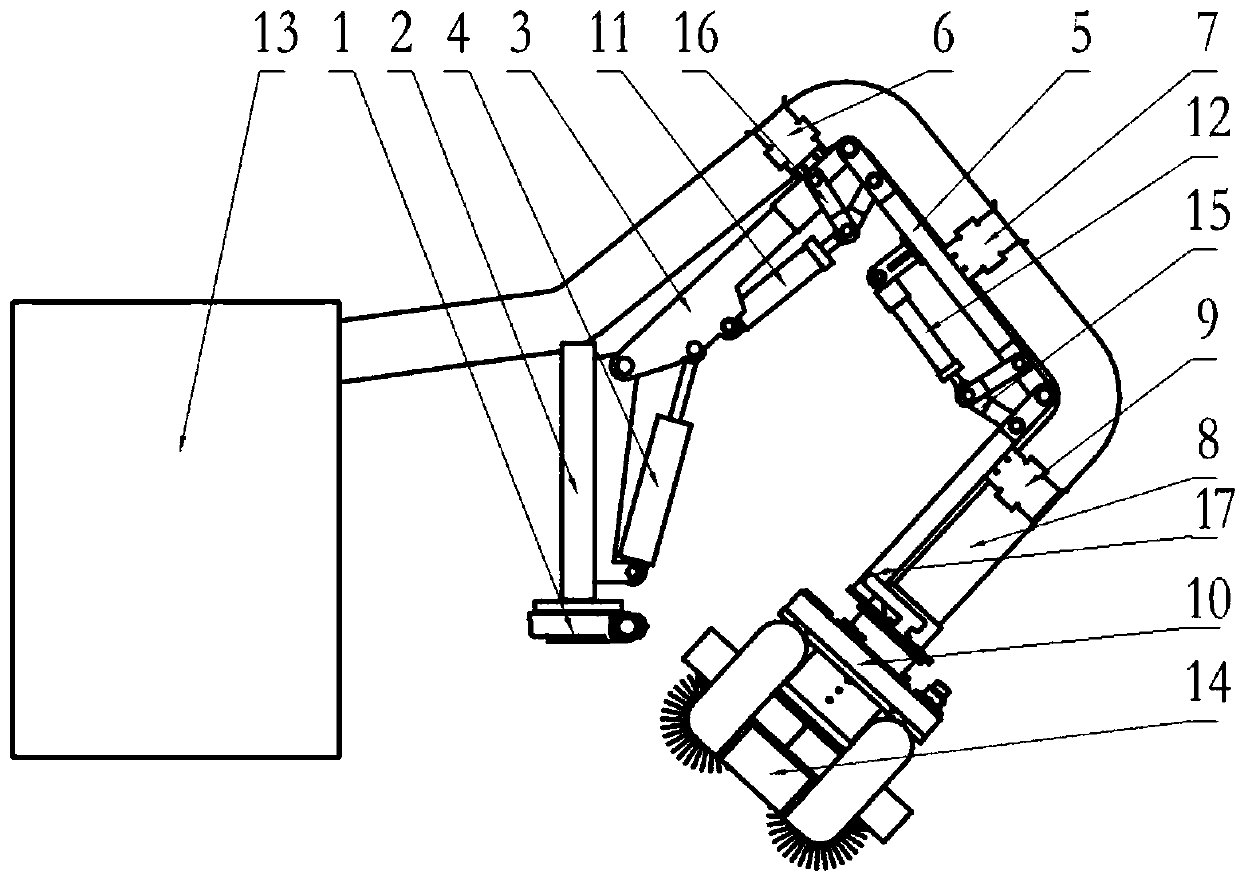

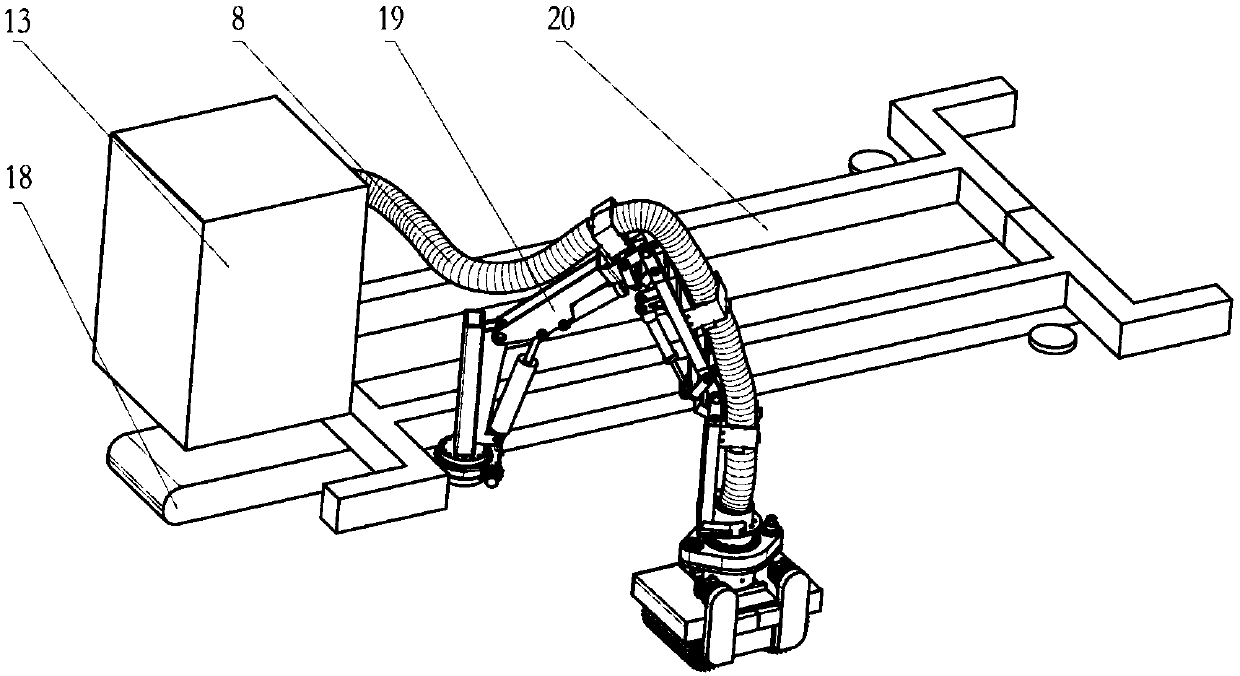

[0052] Embodiment 1.1: a kind of side suction working device of railway sewage suction truck, such as Figure 1-Figure 3 As shown, it includes a side suction operation device 19, which is connected to the dust removal device 13. The side suction operation device 19 includes a rotary support turntable 1, and the rotary support turntable 1 is fixed on the railway sewage suction vehicle frame 20. , and the rotary support turntable 1 is equipped with a rotary motor, and the rotary support turntable 1 rotates around its own vertical axis under the power of the rotary motor; the rotary support turntable 1 is equipped with a mechanical arm II 2, and the end of the mechanical arm II 2 It is hinged with one end of the mechanical arm III 3, the other end of the mechanical arm III 3 is hinged with the head end of the mechanical arm V 5, and the end of the mechanical arm V 5 is hinged with the mechanical arm VII 17; the rotary support turntable 1 is also connected with a suction pipe 8, th...

Embodiment 21

[0062] Embodiment 2.1 A side suction operation method of a railway sewage suction truck, which includes:

[0063] Step S1: Fix the rotary support turntable (1) on the frame of the sewage suction truck, and make the mechanical arm rotate around the vertical axis of the rotary support turntable (1) under the power of the rotary motor of the rotary support turntable (1) , so that the suction device (14) at the end of the suction pipe is rotated to the vicinity of the position to be operated;

[0064] Step S2: the multi-section mechanical arms on the outside of the suction pipe are connected together sequentially in an articulated manner; the end of the mechanical arm II 2 is hinged to one end of the mechanical arm III 3, and the oil cylinder is connected between the mechanical arm III 3 and the mechanical arm V 5 The support hinge VI16, the cylinder support hinge V 15 is connected between the mechanical arm V 5 and the mechanical arm VII 17;

[0065]Step S3: According to the ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com