Organic electrochemical transistor with vertical structure and manufacturing method thereof

A vertical structure and transistor technology, applied in the direction of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as complex processes, shorten channels, etc., and achieve the effects of simple operation, improved performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

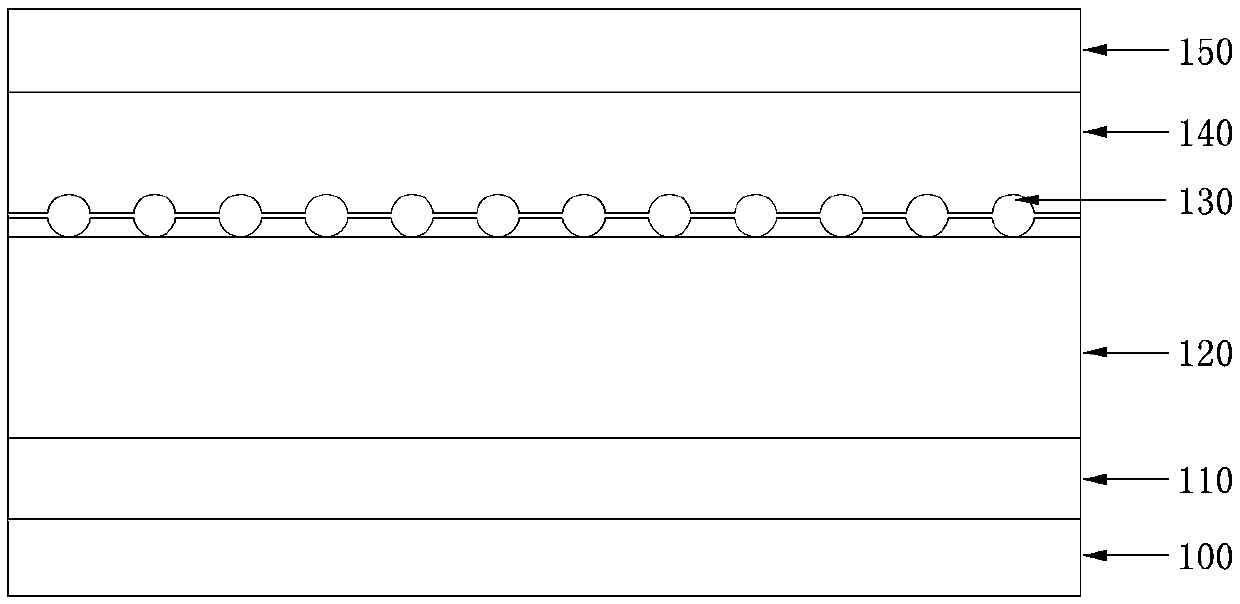

[0026] The present invention also provides a method for preparing the organic electrochemical transistor with the above-mentioned vertical structure, comprising the following steps:

[0027] (1) An active layer film is deposited on a substrate with a patterned drain electrode by a spin-coating process and annealed to obtain an active layer;

[0028] (2) On the active layer obtained in step (1), spin-coat a mesh source electrode film by a spin-coating process and anneal;

[0029] (3) Depositing a polymer ion gel electrolyte on the mesh source electrode obtained in step (2) by spin coating or scraping coating and annealing to obtain an electrolyte layer;

[0030] (4) Preparing a gate electrode on the electrolyte layer obtained in step (3) by thermal evaporation to obtain an organic electrochemical transistor with a vertical structure.

Embodiment 1

[0033] 1) Wash the patterned ITO glass (1.5cm×1.5cm size) with acetone, ethanol, and distilled water (three times), and dry it with nitrogen to obtain a clean glass as the substrate;

[0034] 2) Spin-coat the dispersion of PEDOT:PSS at 1000rpm (60s) to prepare the active layer, and then anneal at 120°C for 1h, and the film thickness is about 200nm;

[0035] 3) On the PEDPT:PSS film obtained in step 2), a silver nanowire solution with a solubility of 1mg / ml was spin-coated at a rotation speed of 2000rpm (60s) to prepare a mesh source electrode, and then annealed at 120°C for 10min;

[0036] 4) Preparation of ion gel electrolyte: polyacrylonitrile, lithium bistrifluoromethanesulfonimide, ethylene carbonate and propylene carbonate were mixed in a mass ratio of 14.1:3.9:41:41 and heated in a 90°C water bath. Stir until clear, transparent colloidal gel state;

[0037] 5) Use a syringe to cover the silicon wafer with the electrolyte gel prepared in step 4), and then spin the soluti...

Embodiment 2

[0040] 1) Clean the patterned ITO glass (1.5cm×1.5cm size) with acetone, ethanol, and distilled water (three times), and dry it with nitrogen to obtain a clean glass as the substrate;

[0041] 2) On the basis of step 1), spread the PEDOT:PSS dispersion on the edge of the junction between the scraper and the silicon wafer. The distance between the scraper and the silicon substrate is 100 μm, and the scraping speed is 20mm / s, and then annealed at 120°C for 1h , the film thickness is about 300-400nm.

[0042] 3) On the basis of step 2), spread the silver nanowire solution with a solubility of 1mg / ml on the edge of the substrate, roll the coating rod along a specific direction at a speed of 20mm / s, and then anneal at 120°C for 10min ;

[0043] 4) Preparation of ion gel electrolyte: polyacrylonitrile, lithium bistrifluoromethanesulfonimide, ethylene carbonate and propylene carbonate were mixed in a mass ratio of 14.1:3.9:41:41 and heated in a 90°C water bath. Stir until clear, tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com