A zero-discharge treatment process and device for oil-containing emulsion wastewater

A treatment process and zero-discharge technology, which is applied in the field of water treatment, can solve the problems affecting the advanced treatment of the demulsification process, the difficulty of zero-discharge treatment of wastewater, and the difficulty of advanced treatment, etc., to achieve easy biodegradation and oxidative degradation, improve service life, The effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

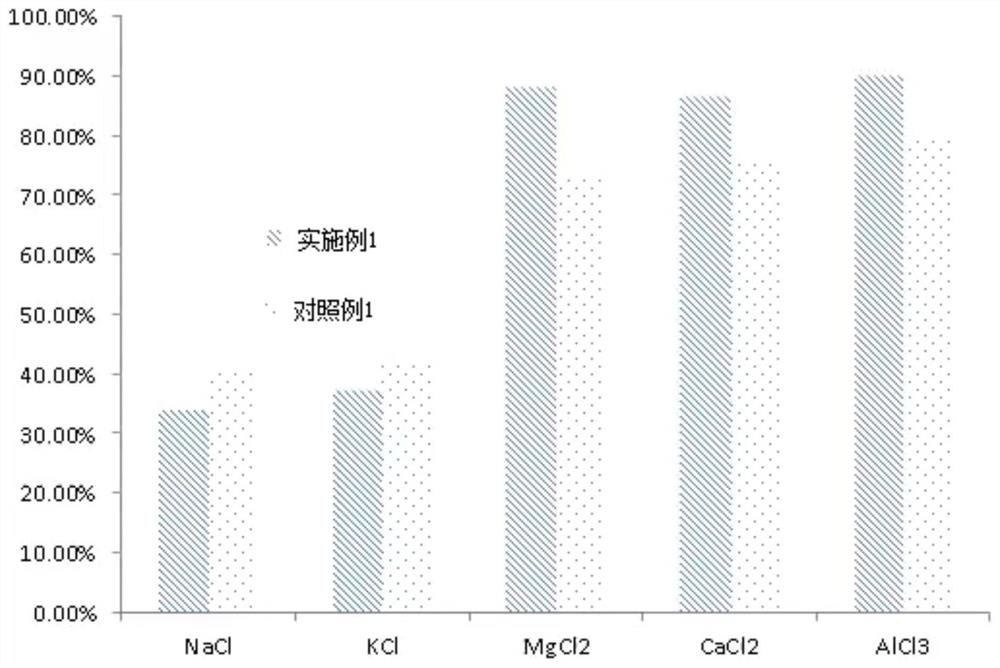

Embodiment 1

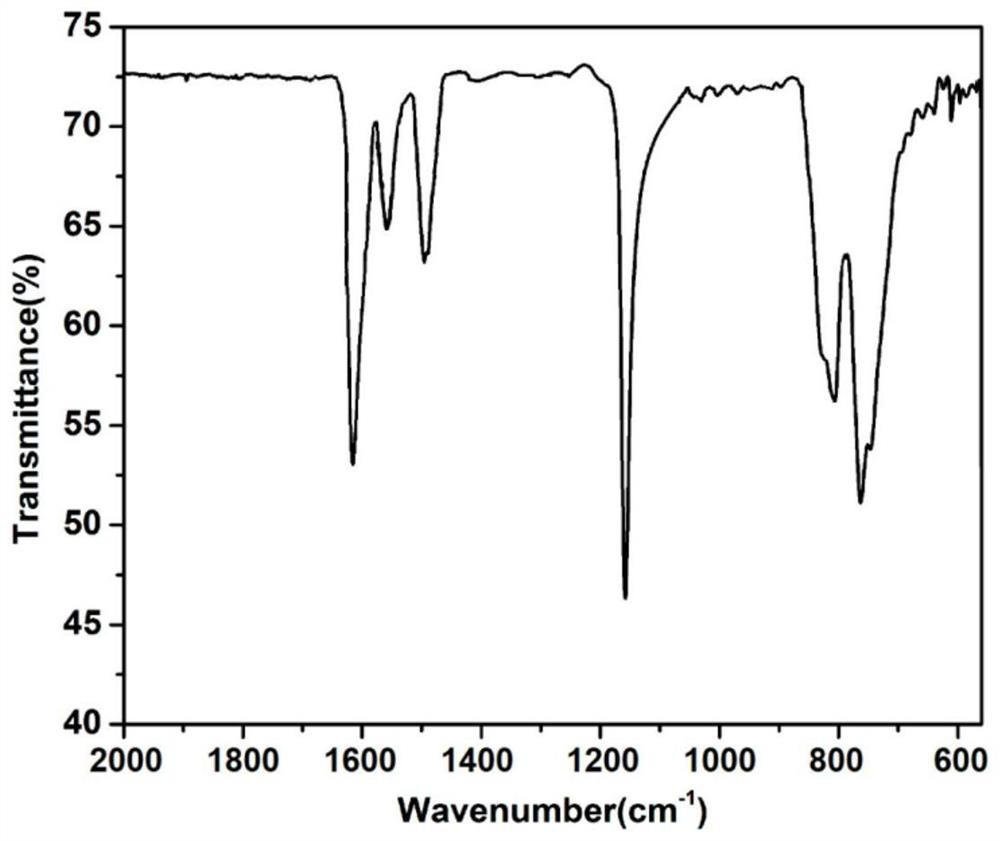

[0060] The preparation of embodiment 1 starch-based demulsifier

[0061] Step 1, modification of active groups: Use 100g of soluble starch, add 350g of water to prepare starch slurry, adjust pH to about 9-10 with NaOH, and then add 35g of sodium hypochlorite solution (active chlorine 13%) to starch slurry for oxidation Reaction, the temperature of the reaction process is 40 ° C, after the reaction time is 4 hours, sodium bisulfite is added to terminate the reaction, the product is concentrated under reduced pressure, crystallized, filtered, washed with ethanol, and dried under reduced pressure to obtain starch modified by active groups;

[0062] Step 2, grafting of adsorption groups: Mix 20g of melamine and 70g of formaldehyde, heat up to 70-75°C and reflux to dissolve melamine; take 50g of active group-modified starch and disperse it in 0.5mol / L ammonia solution 400ml, then slowly added to the melamine-formaldehyde mixture, reflux at 85-90°C for 3 hours, add HCl to make the p...

Embodiment 2

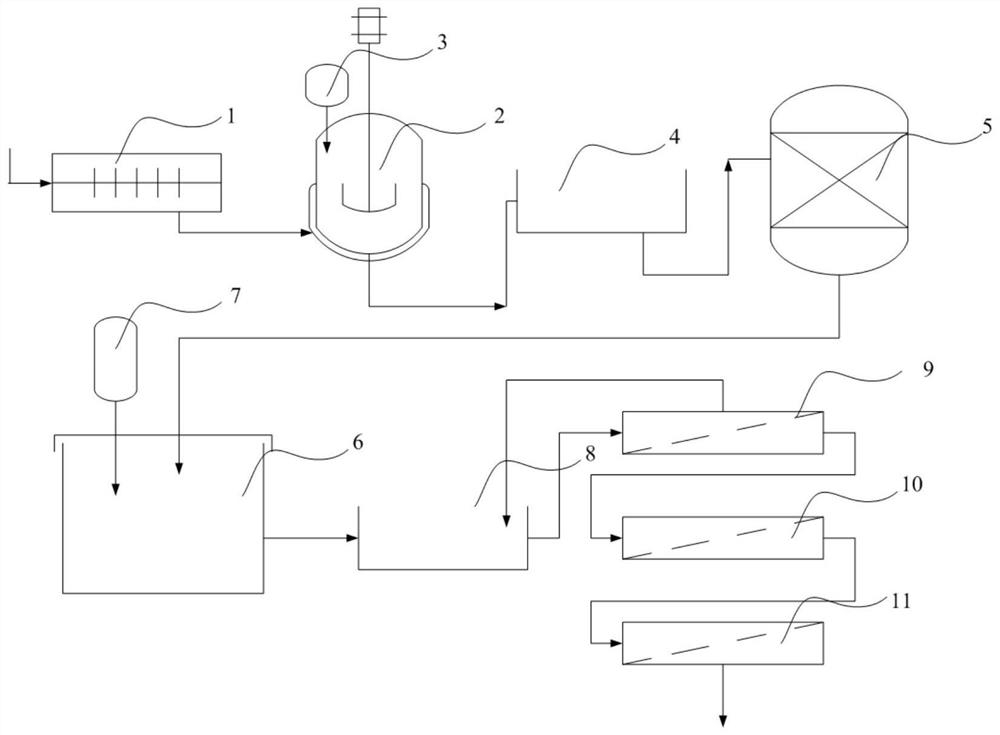

[0078] Example 2 Wastewater Treatment Process

[0079] Step 1, carrying out oil separation treatment on the oilfield produced fluid;

[0080] Step 2. Add 20g / L starch-based demulsifier and 0.2g / L polyacrylamide (PAM) as coagulant aids to the wastewater after oil separation treatment, and perform demulsification treatment. The demulsification temperature is 45°C. Milk time is 70min;

[0081] Step 3, performing the first sedimentation treatment on the wastewater after the demulsification treatment, so that the sediment is removed and the clear liquid is obtained;

[0082] Step 4, Fenton oxidation is carried out to the wastewater after the first sedimentation treatment, Fe 2+ and H 2 o 2 The concentrations are 120mg / L and 400mg / L respectively, the pH value of the system is 3-4, the reaction temperature is 55°C, and the reaction time is 90min;

[0083] Step 5, add flocculant to the wastewater after oxidation treatment for flocculation treatment, the added flocculant is obtained...

Embodiment 3

[0086] Embodiment 3 wastewater treatment process

[0087] Step 1, carrying out oil separation treatment on the oilfield produced fluid;

[0088] Step 2. Add 30g / L starch-based demulsifier and 0.3g / L polyacrylamide (PAM) as coagulant aids to the wastewater after oil separation treatment to perform demulsification treatment. The demulsification temperature is 50°C. Milking time is 90min;

[0089] Step 3, performing the first sedimentation treatment on the wastewater after the demulsification treatment, so that the sediment is removed and the clear liquid is obtained;

[0090] Step 4, Fenton oxidation is carried out to the wastewater after the first sedimentation treatment, Fe 2+ and H 2 o 2 The concentrations are 150mg / L and 450mg / L respectively, the pH value of the system is 3-4, the reaction temperature is 45°C, and the reaction time is 80min;

[0091] Step 5, add flocculant to the wastewater after oxidation treatment for flocculation treatment, the added flocculant is ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com