Quick-hardening cement prepared from waste residues and preparation method thereof

A rapid hardening cement and waste slag technology, which is applied in the field of rapid hardening cement and its preparation, can solve the problems of high maintenance requirements, repair failure, and inability to solve the surface disease of cement concrete structures, so as to alleviate the large and concentrated heat release and accelerate hydration The effect of gentle reaction process and hydration exothermic phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]

[0037] Waste magnesia bricks are made by mixing sintered magnesia bricks and chemically bonded magnesia bricks in a ratio of 1:1, and the mineral admixture is made by mixing fly ash and silica fume in a ratio of 1:1.

[0038] The instant cement is prepared through the following steps: borax is pulverized into powder by a pulverizer; waste magnesia bricks are crushed and ground to a fineness of less than 180 meshes, and 0.2% to 0.8% The organic silane is used as a grinding aid; the raw materials of each component are weighed according to the weight ratio, poured into a mixer and mixed for 20 to 30 minutes to obtain the product of the present invention.

[0039] Mix the prepared rapid-hardening cement with water and sand according to the following ratio to prepare mortar evenly. Rapid-hardening cement:water:sand=1:0.16:1 (mass ratio). The performance test results are shown in Table 1.

Embodiment 2

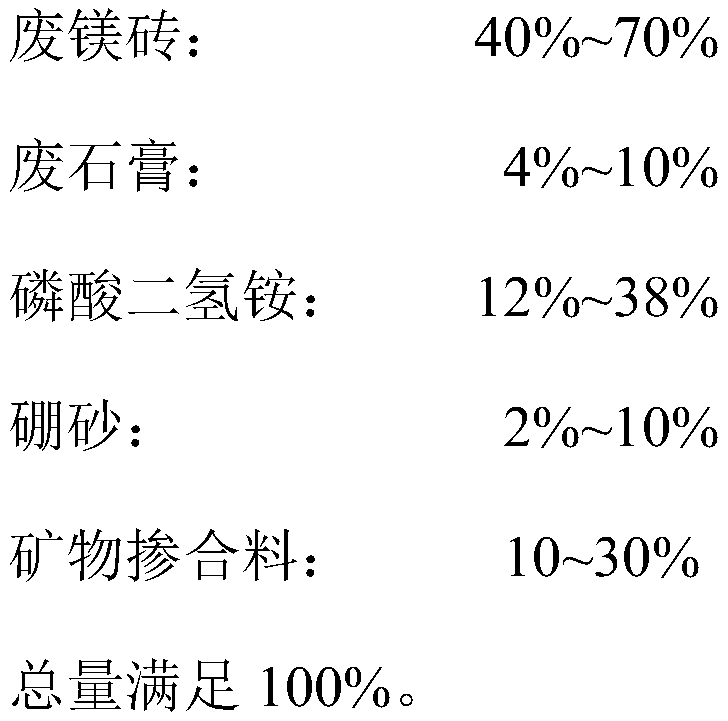

[0041] A kind of rapid hardening cement that utilizes waste slag preparation, the proportioning by weight percentage is as follows:

[0042]

[0043] Waste magnesia bricks are made by mixing chemically bonded magnesia bricks and magnesia-alumina bricks at a ratio of 2:1, and the mineral admixture is made of fly ash and silica fume at a ratio of 2:1. Prepare the patent of the present invention by the step of embodiment 1.

[0044] Mix the prepared rapid-hardening cement with water and sand according to the following ratio to prepare mortar evenly. Rapid-hardening cement:water:sand=1:0.12:1 (mass ratio). The performance test results are shown in Table 1.

Embodiment 3

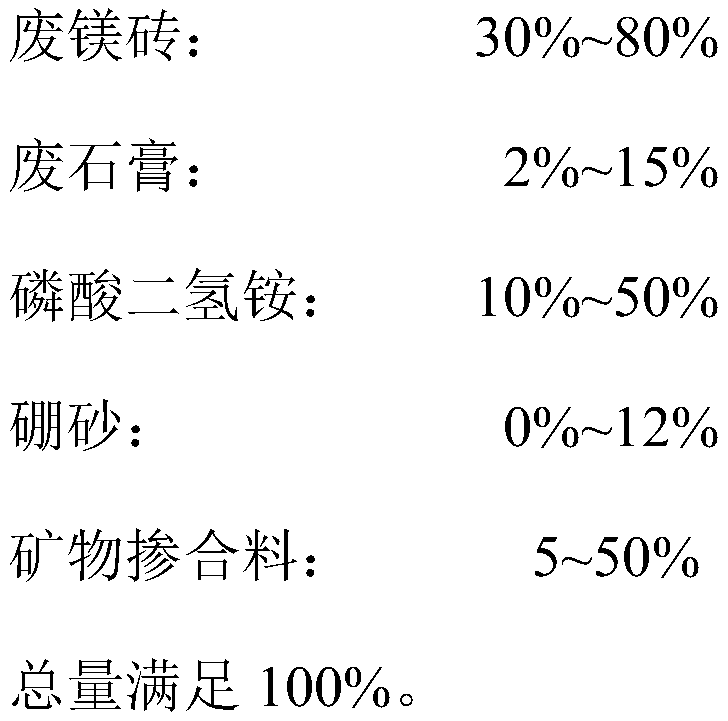

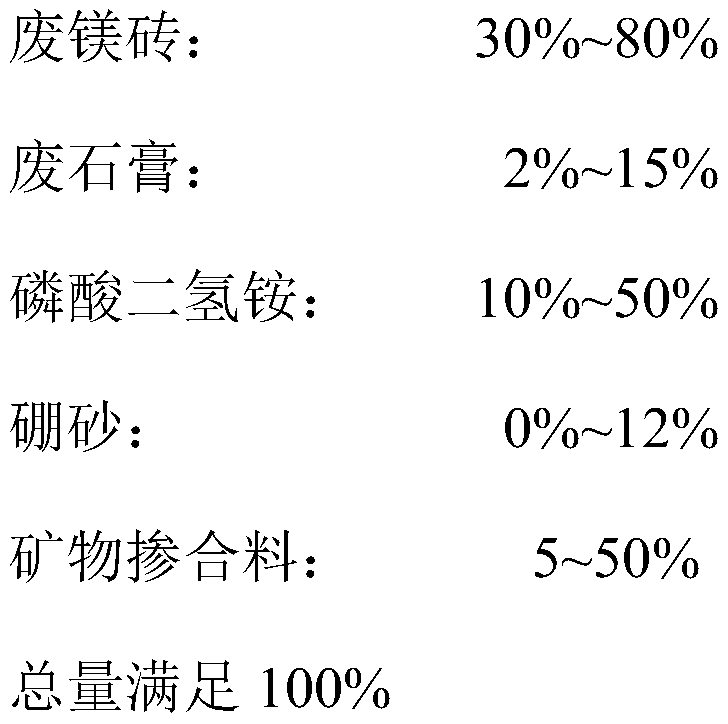

[0046] A kind of rapid hardening cement that utilizes waste slag preparation, the proportioning by weight percentage is as follows:

[0047]

[0048] Waste magnesia bricks are made by mixing sintered magnesia bricks and magnesia-carbon bricks in a ratio of 2:1, and the mineral admixture is made by mixing fly ash and mineral powder in a ratio of 1:1. Prepare the patent of the present invention by the step of embodiment 1.

[0049] Mix the prepared rapid-hardening cement with water and sand according to the following ratio to prepare mortar evenly. Rapid-hardening cement:water:sand=1:0.11:1 (mass ratio). The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com