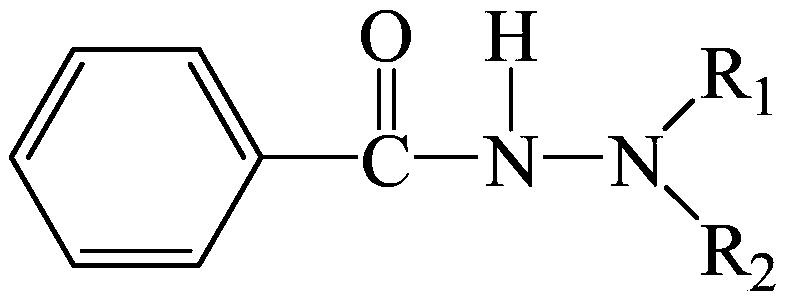

Graphene metal anticorrosive paint for primary equipment in coastal areas and preparation method thereof

A primary equipment and metal anti-corrosion technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of weak metal protection ability, easy agglomeration, uneven conductivity, etc., and achieve the effect of improving anti-corrosion effect and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

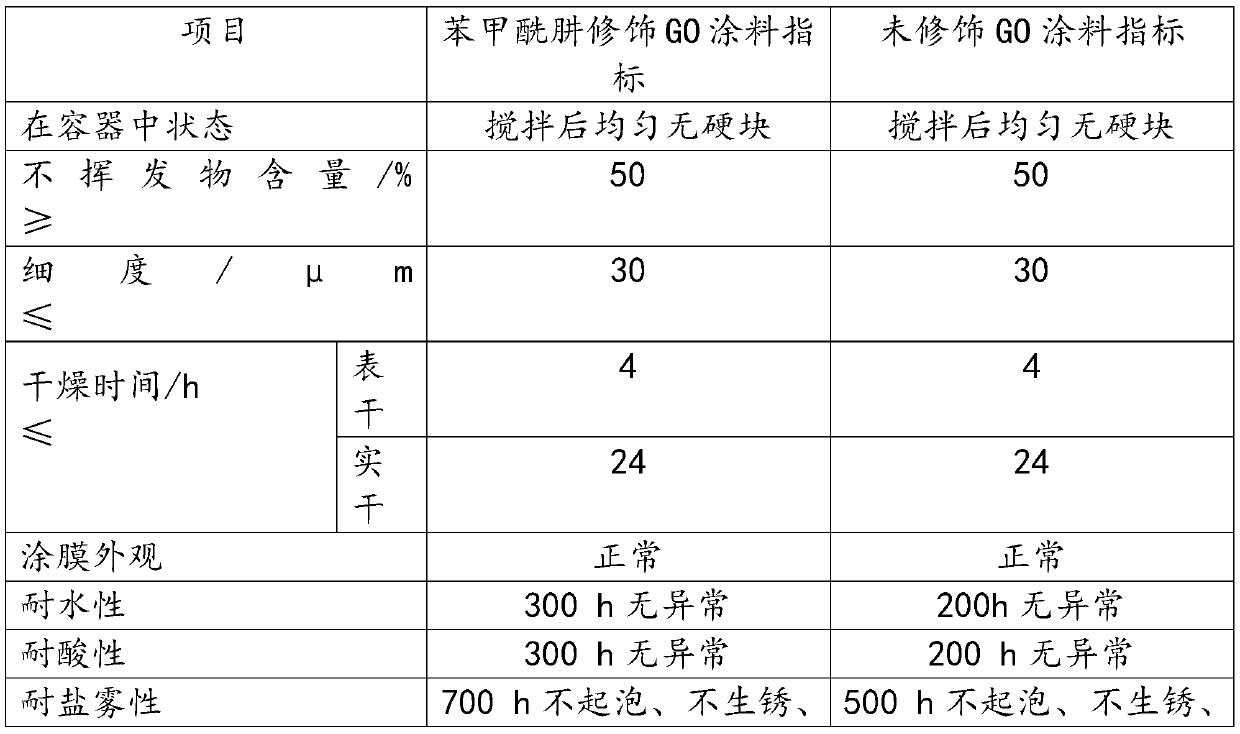

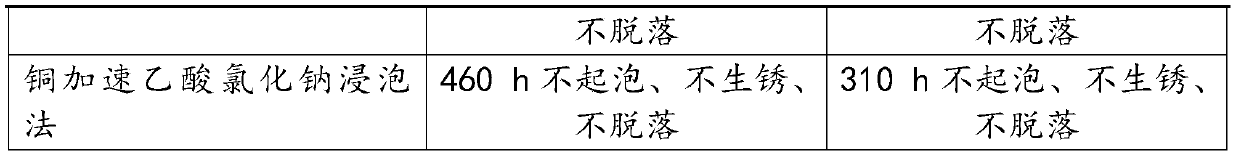

[0032] Include the following components by weight: 70 parts of polyvinylidene fluoride, 0.5 parts of graphene oxide powder modified by benzohydrazide, 5 parts of dispersant, 4 parts of leveling agent, 10 parts of curing agent, 15 parts of diluent, functional 5 parts of permanent filler, 18 parts of mixed solvent.

specific example 2

[0034] The following components are included in parts by weight: 80 parts of polyvinylidene fluoride, 0.4 parts of graphene oxide powder modified by benzohydrazide, 4 parts of dispersant, 5 parts of leveling agent, 5 parts of curing agent, 10 parts of diluent, functional 8 parts of permanent filler, 15 parts of mixed solvent.

specific example 3

[0036] Include the following components by weight: 90 parts of polyvinylidene fluoride, 0.8 parts of graphene oxide powder modified by benzohydrazide, 7 parts of dispersant, 5 parts of leveling agent, 7 parts of curing agent, 13 parts of diluent, functional 9 parts of permanent filler, 16 parts of mixed solvent.

[0037] A kind of preparation method of the modified graphene oxide metal anticorrosion coating of primary equipment in coastal area, comprises the steps:

[0038] Step S1, 50-100 parts of polyvinylidene fluoride and 15-20 parts of mixed solvent are mixed evenly with a high-speed mixer and then added to the paint mixing tank;

[0039] Step S2, turn on the high-speed mixer, add 3-7 parts of dispersant, 2-6 parts of leveling agent, and 1-10 parts of functional filler in sequence, and stir evenly;

[0040] Step S3, after stirring evenly, use a three-roll grinder to grind the paint slurry to a fineness below 30 μm, and then place it in a paint mixing tank;

[0041] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com