Corrosion-resistant hot-rolled steel plate for street lamp post and preparation method thereof

A hot-rolled steel plate and corrosion-resistant technology, which is applied in the field of preparation of corrosion-resistant steel plates, can solve the problems of poor corrosion resistance of hot-rolled steel plates for street lamp poles, reduce corrosion interface expansion, improve corrosion resistance, and excellent plasticity The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

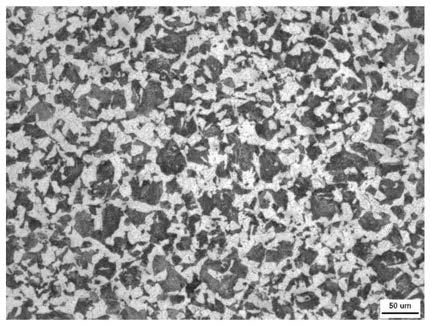

Image

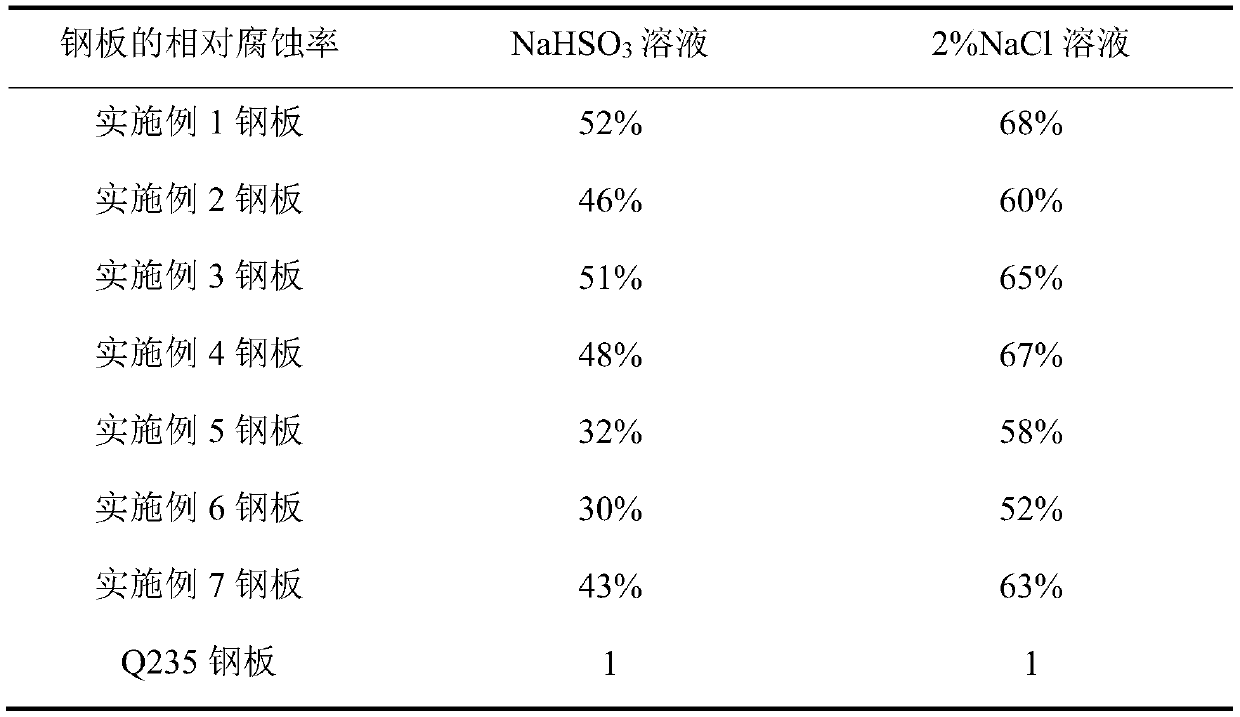

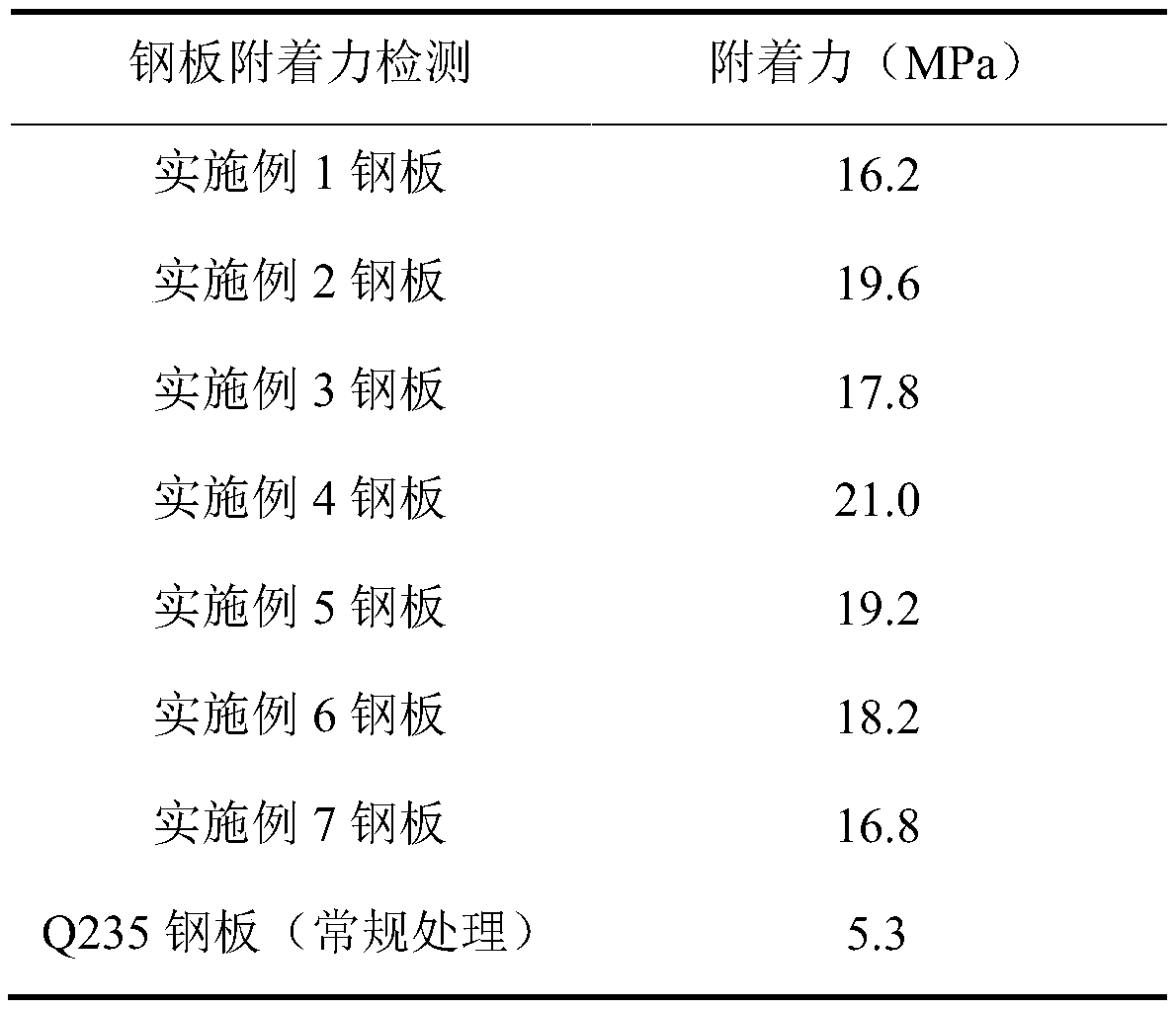

Examples

preparation example Construction

[0043] In another aspect, the present invention provides a method for preparing a corrosion-resistant hot-rolled steel plate for street lamp poles, comprising the following steps:

[0044] Step 1: Put the billet into the heating furnace for heating;

[0045] The steel ingot or rough billet is placed in a heating furnace for heating, and the temperature of the uniform temperature section during the heating process is 1180°C-1250°C. According to the amount of alloy content, adjust the holding time, and the holding time in the uniform temperature section is 2 to 3 hours, so that the alloy elements are completely dissolved and then rolled.

[0046] Step 2: Rough rolling and finishing rolling of the heated billet;

[0047] The rolling temperature of the steel billet is 1130-1200°C, and the temperature range of the final rolling is 950°C-1000°C; it is rolled into a steel plate.

[0048] Step 3: Air-cool the steel plate after finish rolling to obtain a steel plate suitable for stre...

Embodiment 1

[0052] The thickness of the hot-rolled steel plate provided by the present invention is 2.75mm, and the composition of the steel plate is calculated according to weight percentage: C: 0.15%, Si: 0.20%, Mn: 1.6%, P: 0.01%, S: 0.003%, Cu: 0.5% , Cr: 0.5%, Ni: 0.11%, Sn: 0.001%, Sb: 0.02%, Ti: 0.02%, Re: 0.0002%, Ca: 0.0002%, and the balance is iron and unavoidable impurities.

[0053] The preparation method of the above-mentioned corrosion-resistant hot-rolled steel plate for street light poles includes the following steps:

[0054] Step 1: Put the billet into the heating furnace for heating;

[0055] Place the steel ingot or rough billet in a heating furnace for heating, the heating temperature is 1180°C, the heating time is 1.3h, and then rolling is carried out after heating.

[0056] Step 2: Rough rolling and finishing rolling of the heated billet;

[0057] The starting rolling temperature is 1135°C, and the finishing rolling temperature range is 950°C;

[0058] Step 3: Ai...

Embodiment 2

[0061] The thickness of the hot-rolled steel plate provided by the present invention is 4mm, and the composition of the steel plate is calculated according to weight percentage: C: 0.08%, Si: 0.30%, Mn: 0.6%, P: 0.03%, S: 0.025%, Cu: 0.6%, Cr: 1.0%, Ni: 0.3%, Sn: 0.01%, Sb: 0.015%, Ti: 0.001%, Re: 0.03%, Ca: 0.008%, and the balance is iron and unavoidable impurities.

[0062] The preparation method of the above-mentioned corrosion-resistant hot-rolled steel plate for street light poles includes the following steps:

[0063] Step 1: Put the billet into the heating furnace for heating;

[0064] Place the steel ingot or rough billet in a heating furnace for heating, the heating temperature is 1186°C, the heating time is 1.5h, and rolling is carried out after heating.

[0065] Step 2: Rough rolling and finishing rolling of the heated billet;

[0066] The starting rolling temperature is 1140°C, and the finishing rolling temperature range is 980°C; the thickness of the rolled stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com