A pick used for drilling into sand and gravel soil layer and its preparation method

A technology of soil layer and sand and gravel, which is applied in the field of picks for drilling into sand and gravel soil and its preparation. It can solve problems such as difficulty in lubrication, cracking or peeling of the weld layer, and limitations, and achieve improved bonding force and toughness. The effect of increasing the contact area and improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

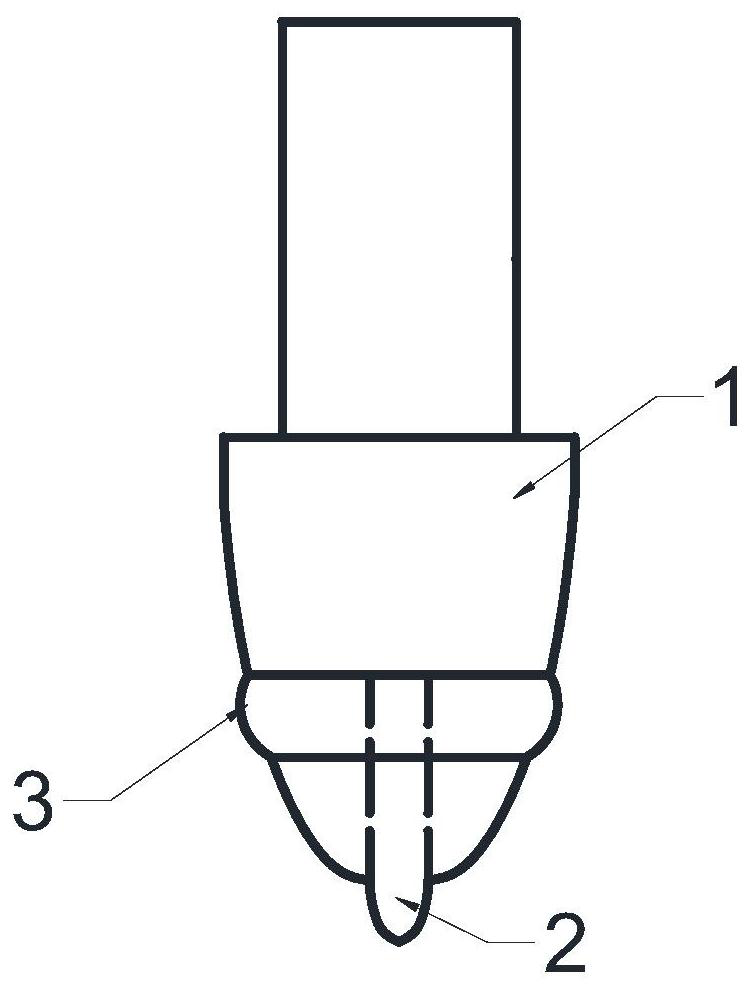

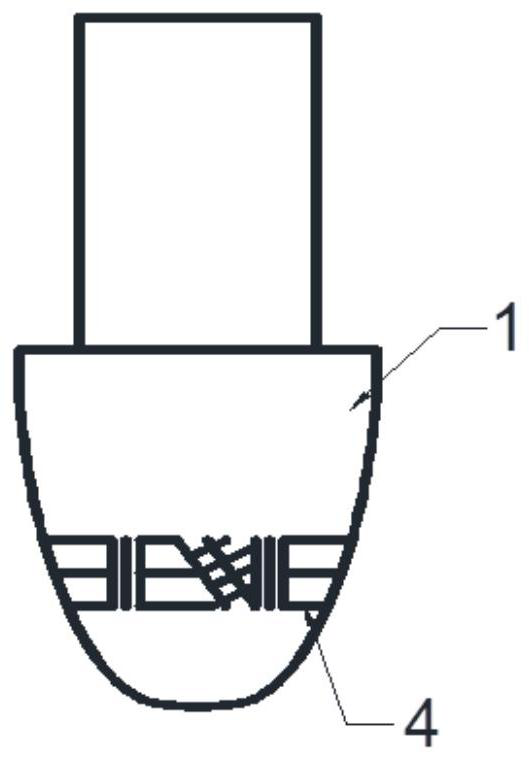

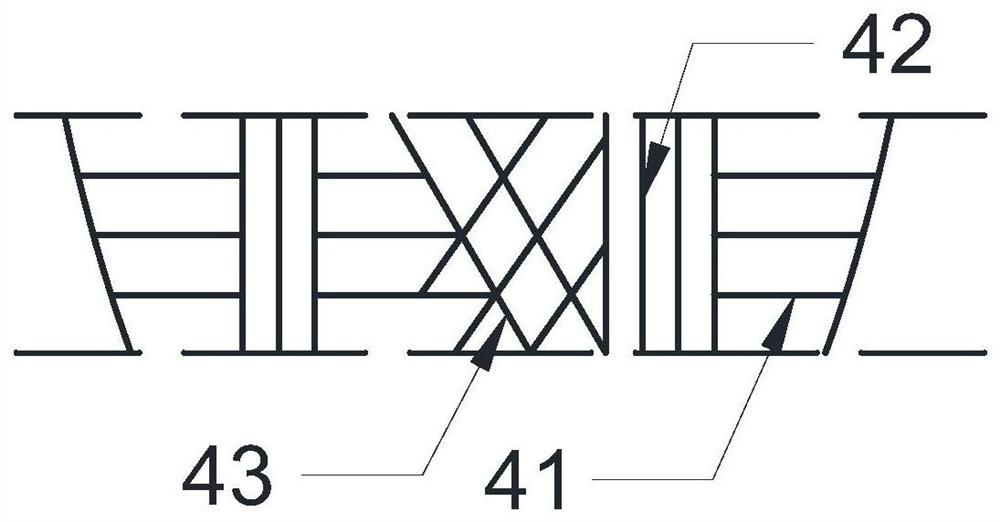

[0030] see figure 1 As shown, a kind of pick used for drilling into sandy gravel soil layer of the present invention comprises cemented carbide head 2 and substrate 1, and described substrate 1 surface is prepared with nickel-based self-fluxing alloy coating 3, and described alloy coating Layer 3 can cover the entire lower part of the pick base to the carbide head, or it can be only a coating with a certain width, which can be determined in combination with actual cost control. see figure 2 and image 3 , the surface of the substrate 1 below the alloy coating 3 is prepared with at least one of the stripe weave 4 types including cross stripes 43, horizontal stripes 41 and vertical stripes 42, and the middle part of the alloy coating 3 is raised , the thickness is the largest, and the thickness of the alloy coating 3 gradually decreases from the middle convex to the upper and lower sides of the substrate, and the surface layer of the alloy coating 3 contains a solid lubricant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com