Preparation method of plasticized specimen

A production method and specimen technology, which is applied in the field of specimen processing, can solve the problems that plasticized specimens are prone to mildew and other problems, and achieve the effects of significant anti-mold effect, prolonging the use time, and improving the anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a method for making a plasticized specimen, comprising the following steps:

[0026] (1) In parts by weight, take 100 parts of hydroxyl-terminated polydimethylsiloxane, add 3.0 parts of dibutyltin and 0.5 parts of tributyltin, stir evenly, and use it as glue A;

[0027] (2) Place the dehydrated and degreased specimen in glue A in the vacuum pressure chamber, the pressure of the vacuum pressure chamber is 0.8-1.2kPa, and let it stand for 10 days to obtain the impregnated specimen;

[0028] (3) Take out the specimen, put it in a warm room at 35-45°C and fumigate it with n-silyl ethyl ester steam for 4 days, so that the specimen is completely cured.

[0029] (4) Trim and tidy the excess silica gel on the cured bone specimen.

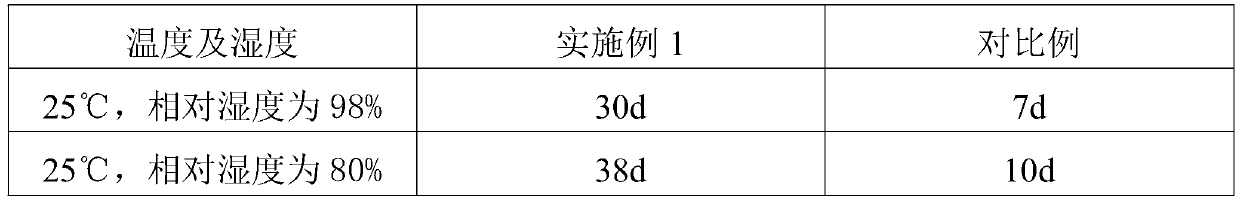

[0030] The plasticized specimen prepared in this embodiment is carried out anti-mold test, compared with the comparative example without adding dibutyltin and tributyltin, the results are as follows:

[0031] tempera...

Embodiment 2

[0034] The invention provides a method for making a plasticized specimen, comprising the following steps:

[0035] (1) In parts by weight, take 100 parts of hydroxyl-terminated polydimethylsiloxane, add 2.5 parts of dibutyltin and 0.5 parts of tributyltin, stir evenly, and use it as glue A;

[0036] (2) Place the dehydrated and degreased specimen in glue A in the vacuum pressure chamber, the pressure of the vacuum pressure chamber is 0.8-1.2kPa, and let it stand for 8 days to obtain the impregnated specimen;

[0037] (3) Take out the specimen, put it in a warm room at 35-45°C and fumigate it with n-silane ethyl ester steam for 5 days, so that the specimen is completely cured.

[0038] (4) Trim and tidy the excess silica gel on the cured bone specimen.

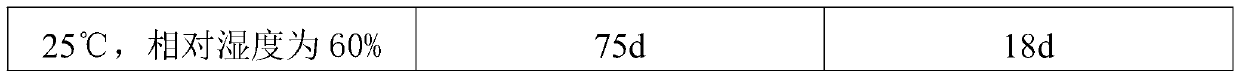

[0039] The plasticized specimen prepared in this embodiment is carried out anti-mold test, compared with the comparative example without adding dibutyltin and tributyltin, the results are as follows:

[0040] tempera...

Embodiment 3

[0043] The invention provides a method for making a plasticized specimen, comprising the following steps:

[0044] (1) In parts by weight, take 100 parts of hydroxyl-terminated polydimethylsiloxane, add 4.5 parts of dibutyltin and 0.5 parts of tributyltin, stir evenly, and use it as glue A;

[0045] (2) Place the dehydrated and degreased specimen in glue A in the vacuum pressure chamber, the pressure of the vacuum pressure chamber is 0.8-1.2kPa, and let it stand for 12 days to obtain the impregnated specimen;

[0046] (3) Take out the specimen, put it in a warm room at 35-45°C and fumigate it with n-silane ethyl ester steam for 3 days, so that the specimen is completely cured.

[0047] (4) Trim and tidy the excess silica gel on the cured bone specimen.

[0048] The plasticized specimen prepared in this embodiment is carried out anti-mold test, compared with the comparative example without adding dibutyltin and tributyltin, the results are as follows:

[0049] temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com