Composition containing triazolopyrimidine derivative mixture and purpose of composition

A technology of the first triazolopyrimidine and azolopyrimidine, which is applied in the direction of medical preparations containing active ingredients, plant raw materials, organic active ingredients, etc., and can solve problems that need to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0068] The preparation of preparation example 1 plant extract

[0069] Ultrasonic extraction method is used to dry the shade-dried plant material at 40°C, crush it, pass through a 40-mesh sieve, and put it into a ziplock bag. Before the test, 50 g of plant dry powder was weighed, and different organic solvents were added for ultrasonic extraction (as shown in Table 1), and the extraction was repeated 3 times for 60 min each time. After filtration, it was concentrated to dryness and stored in a refrigerator at 4°C until use.

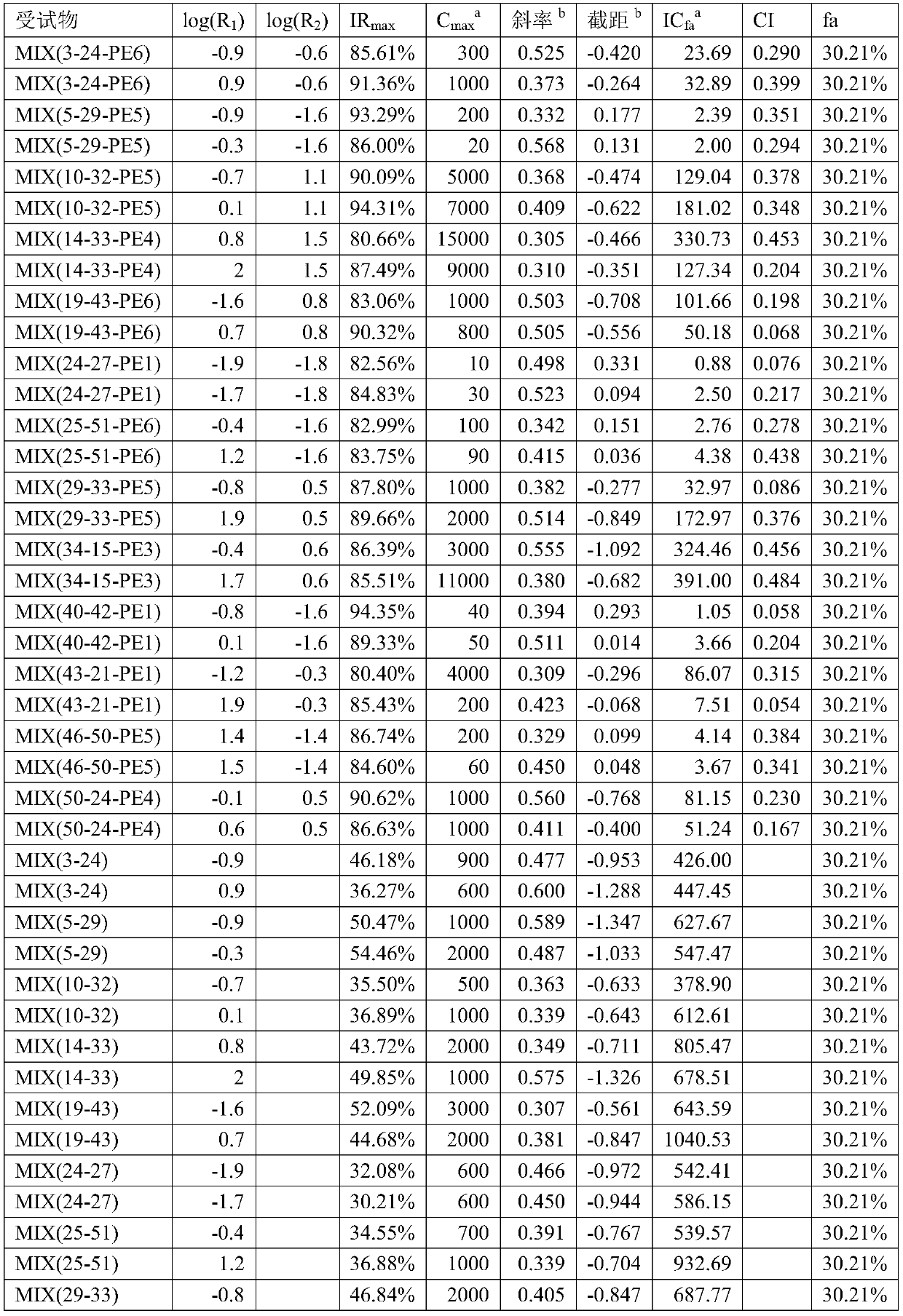

[0070] Table 1 Organic solvents for ultrasonic extraction of different plant extracts

[0071] plant material Extract number Organic solvent for extraction hairy tiger PE1 Isopropanol red yaozi PE2 n-heptane white diamond PE3 Methanol Bone style PE4 acetone june snow PE5 ethanol Peace of mind PE6 Methanol

Embodiment 1

[0142] Embodiment 1 Preparation of solid formulation containing the composition of triazolopyrimidine derivative mixture

[0143] prescription

[0144]

[0145]

[0146]

[0147] Preparation

[0148] The active ingredients and auxiliary materials of the prescribed amount are all passed through a 100-mesh sieve. Get the active ingredient, lactose, microcrystalline cellulose, crospovidone and starch and mix thoroughly; get the hypromellose of the prescription amount, and prepare a solution with a concentration of 10% based on hypromellose, add lactic acid Adjust the pH to 3.0-4.0, add it to the above-mentioned mixture to make a soft material, granulate with a 16-mesh sieve, and dry at 80°C for 3-4 hours. Use a 16-mesh sieve to sieve, add the prescribed amount of micropowder silica gel and magnesium stearate, mix well, and fill into capsules with a weight of about 500 mg each;

[0149] The active ingredients and auxiliary materials of the prescribed amount are all p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com