Roof prism machining technology

A technology of roof prism and processing technology, which is applied in the direction of metal processing equipment, manufacturing tools, work carriers, etc., can solve the problems of low production efficiency, pass rate and product precision, achieve efficiency improvement, improve product precision, pass rate and precision Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

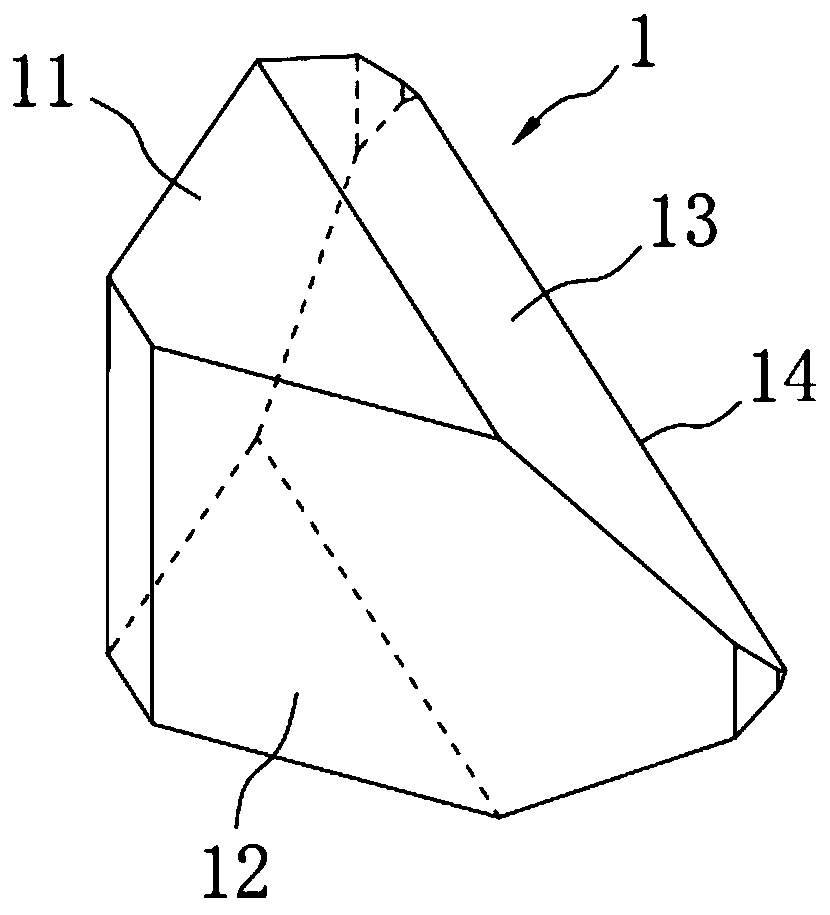

[0051] A kind of roof prism processing technology in this embodiment is specially used in processing production such as figure 1 The roof prism 1 shown in , the roof prism 1 is an isosceles right-angle roof prism, including two side surfaces 11, two mutually perpendicular right-angle surfaces 12 and two mutually perpendicular roof surfaces 13, the two roof surfaces 13 intersect to form a roof prism 14. The production and processing steps are as follows:

[0052] S01, take the roof prism wool, first grind and process two sides 11; the roof prism wool is an isosceles right-angle prism;

[0053] S02, grinding and polishing the large surface of the roof prism wool, and processing the surface where the roof prism 14 is located, which is the large surface of the processed roof prism wool;

[0054] S03, using the surface of the roof ridge 14 for positioning, grinding and polishing to process two right-angled surfaces 12;

[0055] S04 , using the side surfaces 11 for positioning, g...

Embodiment 2

[0059] A kind of roof prism processing technology in this embodiment, the basic steps are the same as embodiment 1, the difference and improvement are that the processing steps of the side 11 are:

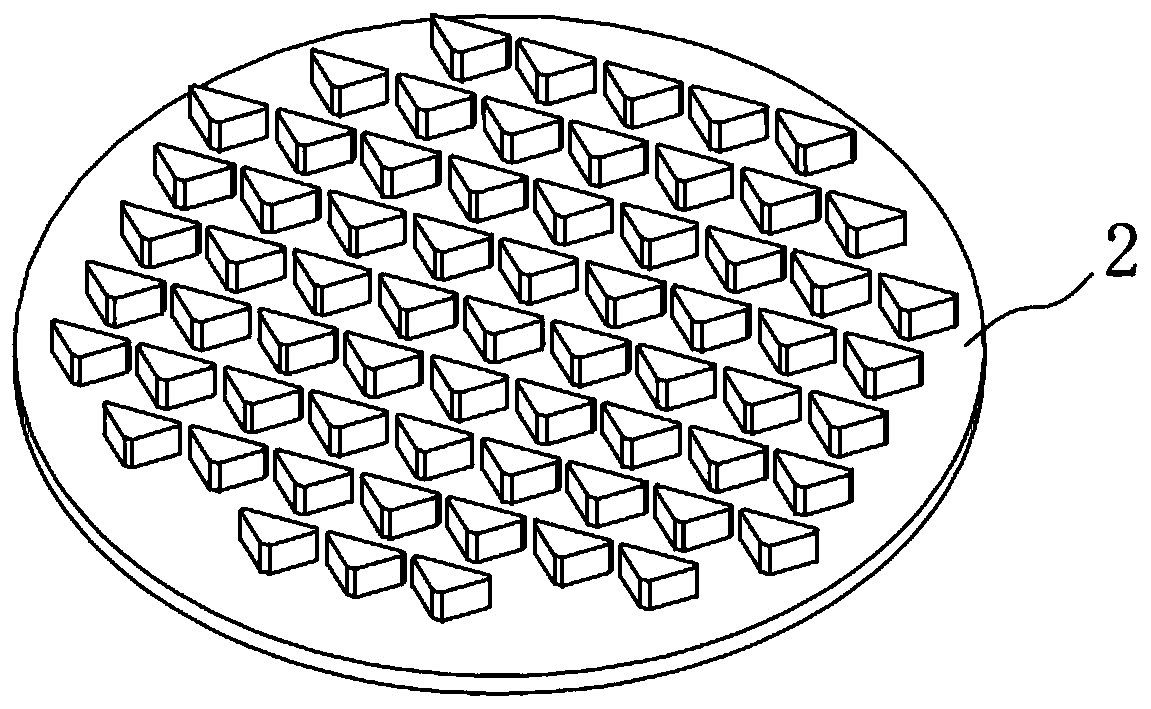

[0060] i. Wipe one side of the roof prism wool with acetone reagent, then place it on the tray 2 with this side facing down, and drop optical glue on the lower end of the roof prism wool to fix it, and let it stand for about 10 minutes until The glue is completely dry, and protective paint is smeared around the roof prism wool to prevent water from seeping into the ground of the roof prism wool during subsequent processing, causing the roof prism wool to fall off from the pallet 2; the pallet described in this embodiment 2 has a diameter of 300mm, and each tray can place about 100 pieces of said roof prism wool;

[0061] ⅱ, such as figure 2 As shown in , place the entire tray 2 evenly on the two-axis machine, and grind the side facing the roof prism wool from top to bottom, with ...

Embodiment 3

[0066] A kind of roof prism processing technique in the present embodiment, basic steps are the same as embodiment 1 and 2, difference and improvement are that, the processing steps of the surface where described roof ridge 14 is:

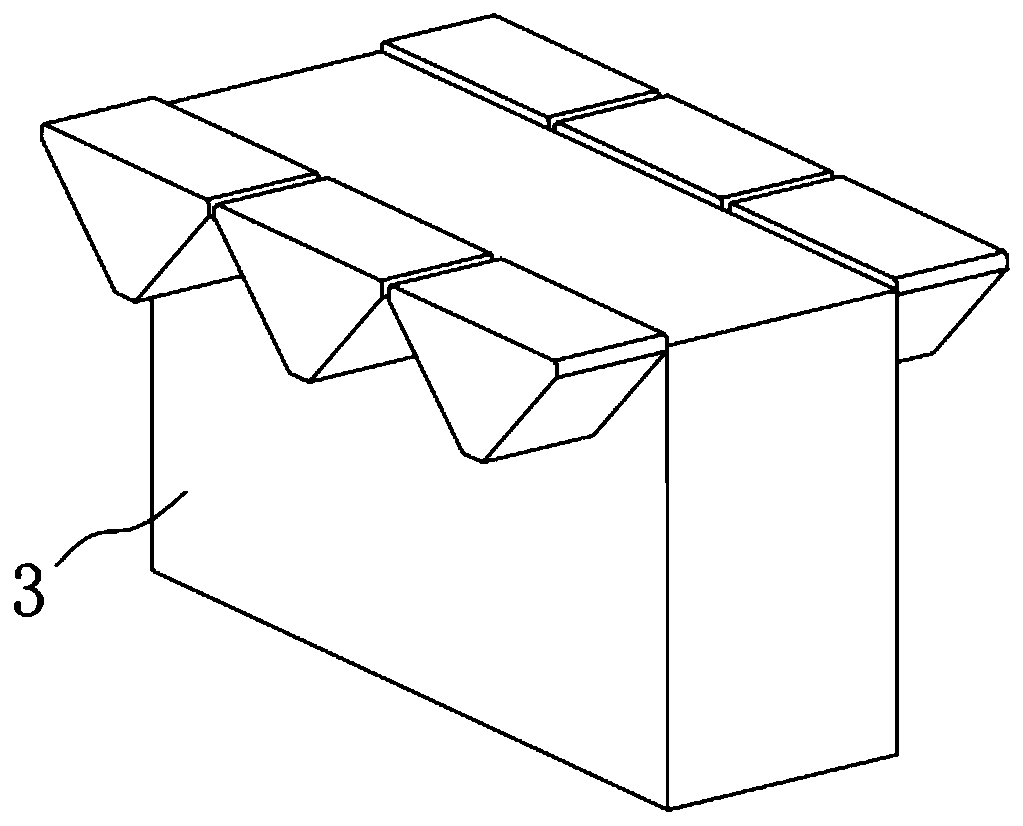

[0067] ⅰ, such as image 3 As shown in , prepare a backing body I3 with length×width×height=75mm×25mm×50mm, and glue one of the side surfaces 11 to the side of the backing body I3 with optical glue to ensure that the large surface of the roof prism wool is horizontally facing On and higher than the upper end of the body I3, 6 pieces are fixed on each body I3, and then the lower end of the body I3 is fixed on the tray 2 with optical glue, and 10 pieces are fixed on each plate;

[0068] ⅱ. Place the full tray 2 evenly and put the whole tray in the two-axis machine, and grind the large surface of the roof prism wool from top to bottom. The grinding size error is controlled within 0.005mm, and the surface flatness is controlled within 0.001mm , the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com