A kind of production method of 2,4,6-tris(dimethylaminomethyl)phenol

A production method of dimethylaminomethyl, which is applied in the field of epoxy resin curing catalyst preparation, can solve the problems of increasing the difficulty of wastewater treatment and low yield, reduce the amount of amine substances and wastewater, and improve Yield and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

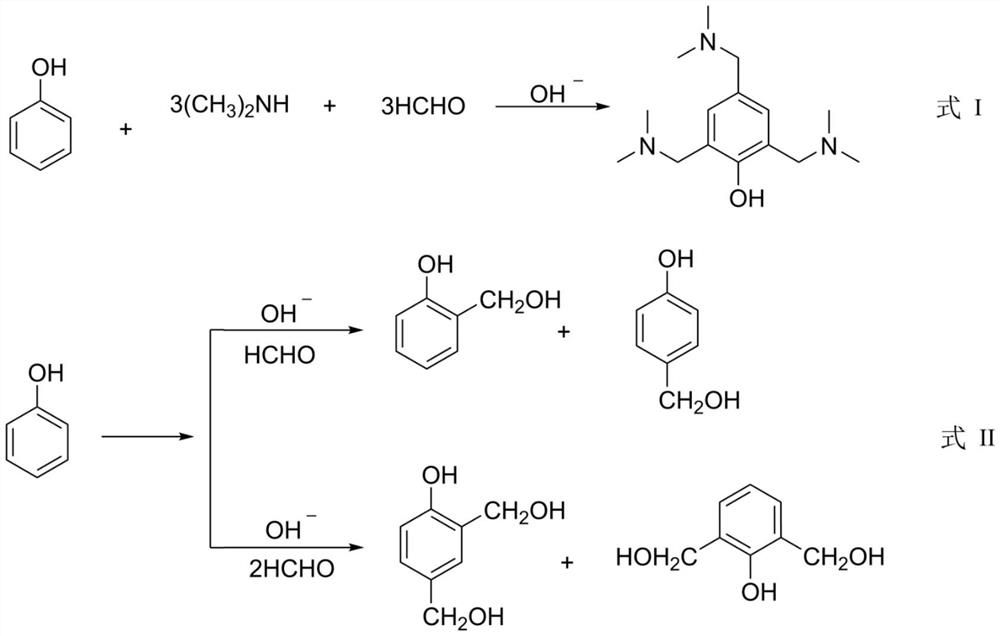

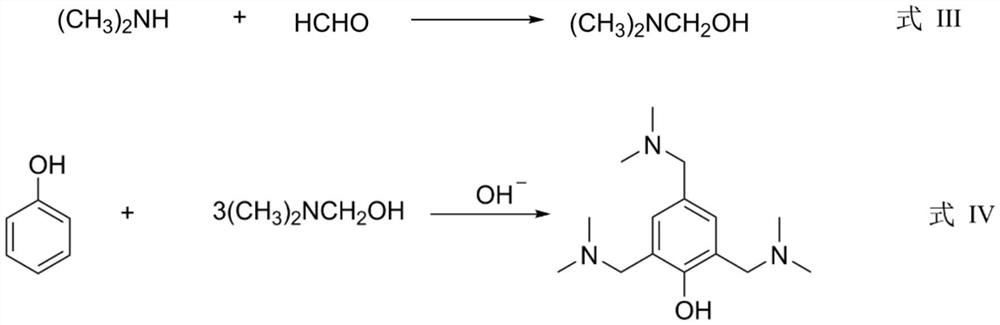

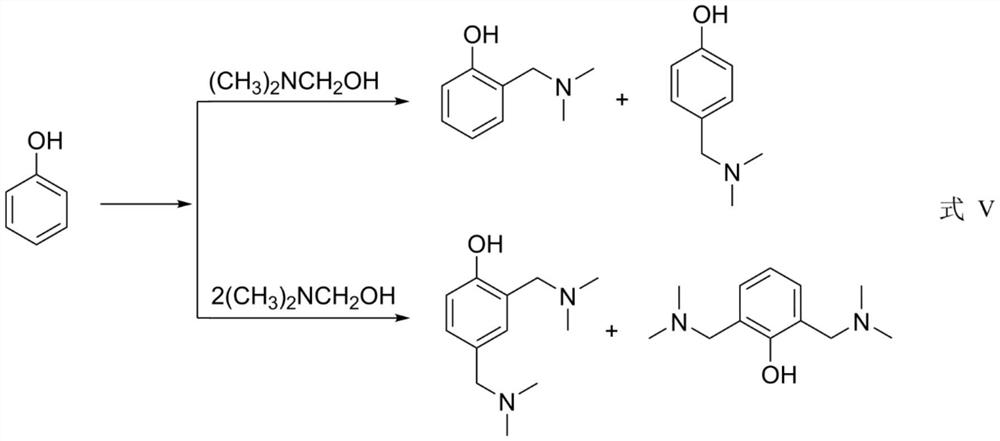

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] (1) Weigh 1800kg dimethylamine (concentration 40wt%) and add 6m 3 The intermittent stirring reactor, the stirring speed is controlled at 40r / min, then weighed 1000kg of formaldehyde (concentration 40wt%), controlled by a metering pump and added to the dimethylamine aqueous solution to react within 1.5 hours, and the temperature was raised to 60°C after the feeding was completed. Under the pressure of 0.4Mpa (with a certain pressure, which can effectively avoid the gasification and material loss of formaldehyde and dimethylamine caused by the increase in reactivity), react for 2 hours to obtain a solution system;

[0030] (2) Weigh 120kg of phenol, control it with a metering pump and add it into the solution system obtained in step (1) within 1.5 hours, then raise the temperature to 90°C, react for 3 hours, let stand to separate layers, separate oil and water, the lower layer is the water phase, enter Water phase st...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] (1) Weigh 3600kg dimethylamine (concentration 40wt%) and add 6m 3 The intermittent stirring reactor, the stirring speed is controlled at 40r / min, then weighed 1800kg of formaldehyde (concentration 40wt%), controlled by a metering pump and added to the dimethylamine aqueous solution to react within 2.5 hours, and the temperature was raised to 60°C after the feeding was completed. Under the pressure of 0.4Mpa (with a certain pressure, which can effectively avoid the gasification and material loss of formaldehyde and dimethylamine caused by the increase in reactivity), react for 2.5 hours to obtain a solution system;

[0035] (2) Weigh 180kg of phenol, and use a metering pump to control it and add it into the solution system obtained in step (1) within 1.5 hours, then raise the temperature to 90°C, react for 2 hours, leave to separate layers, separate oil and water, the lower layer is the water phase, enter Water phas...

Embodiment 3

[0038] This embodiment includes the following steps:

[0039] (1) Weigh 3600kg dimethylamine (concentration 40wt%) and add 6m 3 The intermittent stirring reactor, the stirring speed is controlled at 40r / min, then weighed 1600kg of formaldehyde (concentration 40wt%), controlled by a metering pump and added to the dimethylamine aqueous solution to react within 2.5 hours, and the temperature was raised to 50°C after the feeding was completed. Under the pressure of 0.4Mpa (with a certain pressure, which can effectively avoid the gasification and material loss of formaldehyde and dimethylamine caused by the increase in reactivity), react for 3 hours to obtain a solution system;

[0040] (2) Weigh 160kg of phenol, and use a metering pump to control it and add it into the solution system obtained in step (1) within 1.5 hours, then raise the temperature to 90°C, react for 3 hours, leave to separate layers, separate oil and water, the lower layer is the water phase, enter Water phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com