Spiro ethylene glycol-based copolyester and preparation method and product thereof

A technology of spiroethylene glycol and copolyester, which is applied in the field of spiroethylene glycol-based copolyester and its preparation, which can solve the uncontrollable degradation process of degradable materials, the inability to meet the toughness at the same time, and the impact of degradation speed It can improve the glass transition temperature and temperature resistance, broaden the mechanism and scope, and achieve the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method based on spiroethylene glycol copolyester, comprising:

[0028] S1, mixing spiroethylene glycol with the first component, the second component, and an esterification catalyst, and performing an esterification reaction at a first temperature to obtain an esterified product, wherein the first component is a binary Acid and / or dibasic acid ester compound, the second component is aliphatic dihydric alcohol;

[0029] S2, the esterification product is subjected to polycondensation reaction at a second temperature to obtain a copolyester based on spiroethylene glycol, and the structural formula of the copolyester is shown in the following formula (1):

[0030]

[0031] Among them, R 1 is a structural unit corresponding to the first component a, R 2 As a structural unit corresponding to the second component c, x and y are both integers, and the ratio of x to y is 10:1˜1:10.

[0032] Spiroethylene glycol contains an aceta...

Embodiment 1

[0063] Add 43.8g (0.3mol) of 1,4-dimethyl succinate, 29.4g (0.326mol) of 1,4-butanediol, and 53.0g (0.174mol) of spiroethylene glycol into the reactor, and then 0.1% of the total mass of tetrabutyl titanate was added, and under the protection of high-purity nitrogen, it was reacted at 180-200° C. for 5 hours to obtain an esterification product.

[0064] Continue to add 0.2% antimony trioxide, 0.5% phosphoric acid and 0.5% antioxidant 1010 to the reactor, gradually reduce the vacuum to 1000Pa, and then reduce the pressure to less than 50Pa after 30 minutes, and react at 240°C After 6 hours, a white copolyester product was obtained.

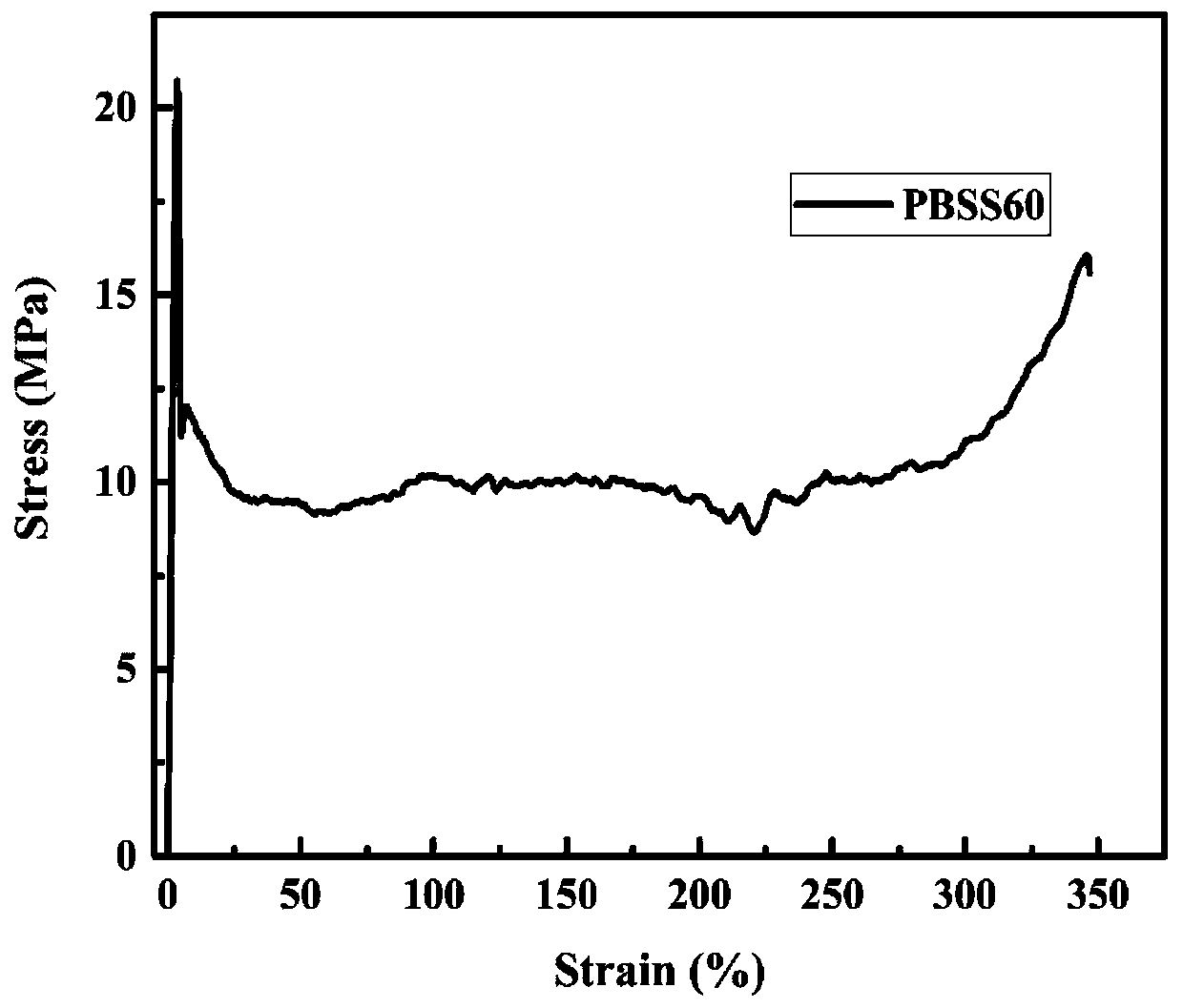

[0065] Tests such as nuclear magnetic resonance, DSC, TGA, mechanical properties, molecular weight, intrinsic viscosity, and degradation performance were carried out on the copolyester respectively.

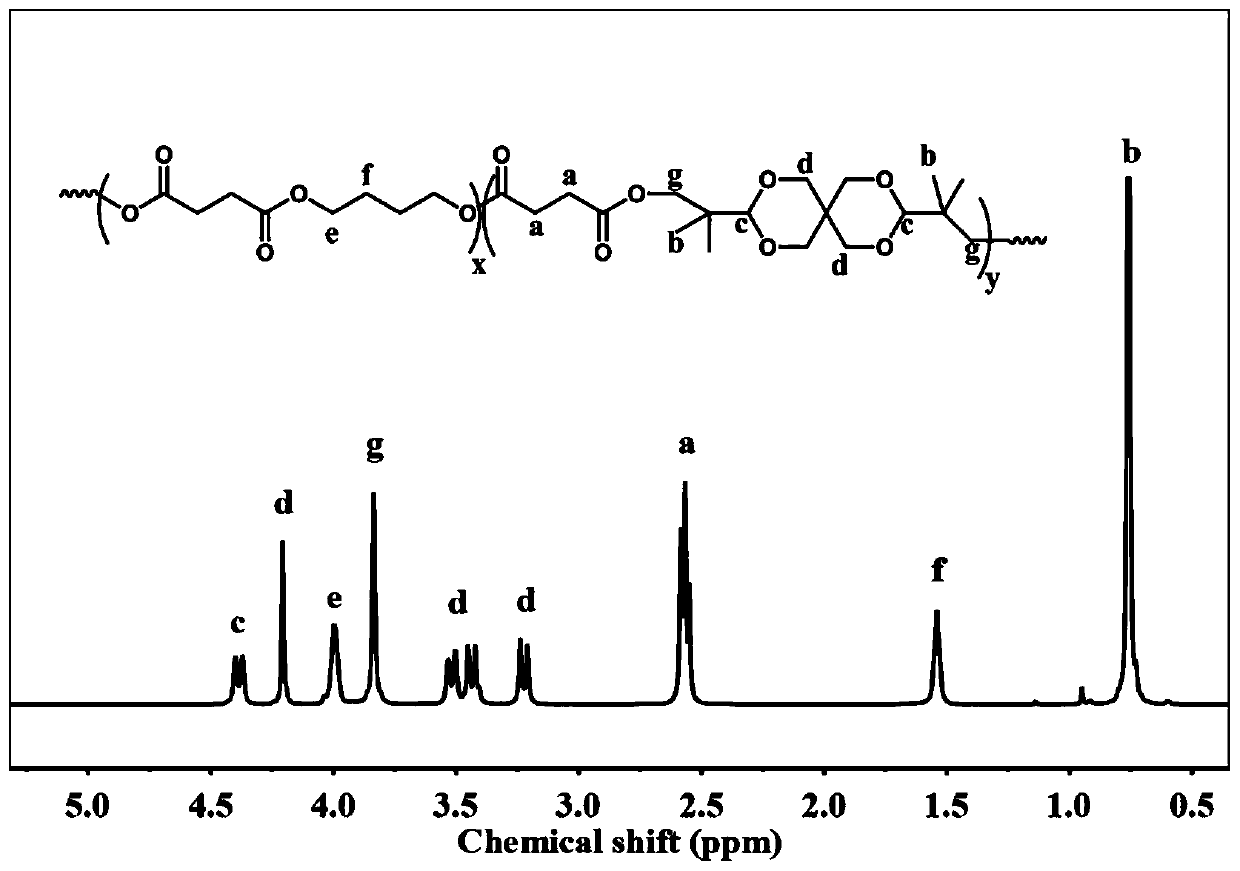

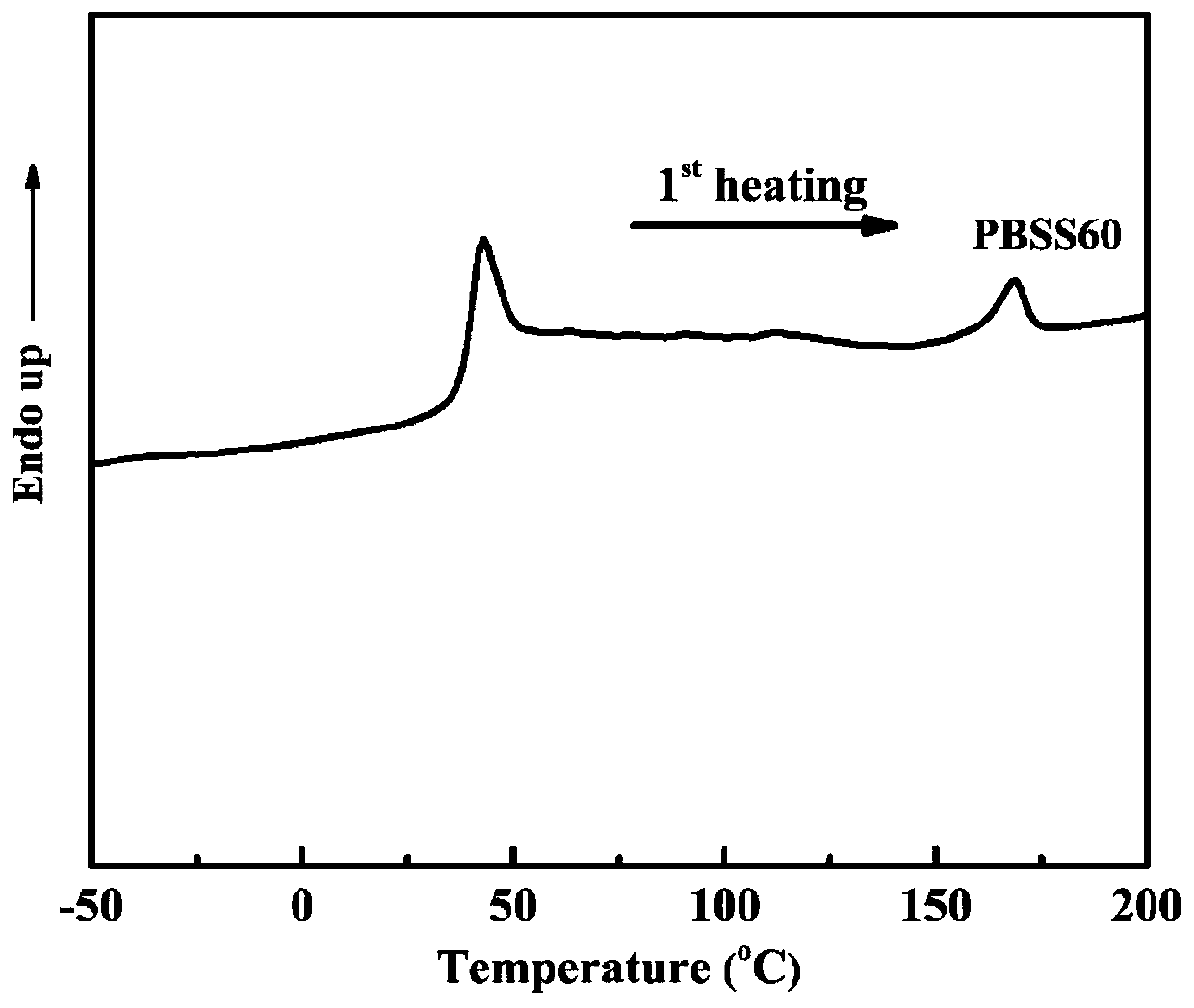

[0066] figure 1 , figure 2 Contains the NMR and DSC primary temperature rise diagrams of the copolyester. From figure 1 It can be seen that the...

Embodiment 2

[0074] Add 43.8g (0.3mol) of 1,4-dimethyl succinate, 34.8g (0.386mol) of 1,4-butanediol, and 34.7g (0.114mol) of spiroethylene glycol into the reactor, and then 0.2% of the total mass of anhydrous zinc acetate is added, and under the protection of high-purity nitrogen, the reaction is carried out at 170-190° C. for 4 hours to obtain an esterification product.

[0075] Continue to add 0.2% tetrabutyl titanate, 0.4% triphenyl phosphate and 0.6% antioxidant 1010 to the reactor, gradually reduce the vacuum to 500Pa, and reduce the pressure to less than 30Pa after 30 minutes , 220 ° C for 5 hours to obtain a white copolyester product.

[0076] Tests such as nuclear magnetic resonance, DSC, TGA, mechanical properties, molecular weight, intrinsic viscosity, and degradation performance were carried out on the copolyester respectively. It can be seen from the nuclear magnetic resonance test that the copolyester has a clear structure, and the ratio of the number of structural units of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com