Water-based gravure scratch-resistant wear-resistant finishing varnish applied to surface of paint-free veneering paper of panel furniture and preparation method thereof

A panel furniture, gravure printing technology, applied in the direction of biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problem of low energy consumption, achieve strong pollution resistance, reduce energy and human resource consumption , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

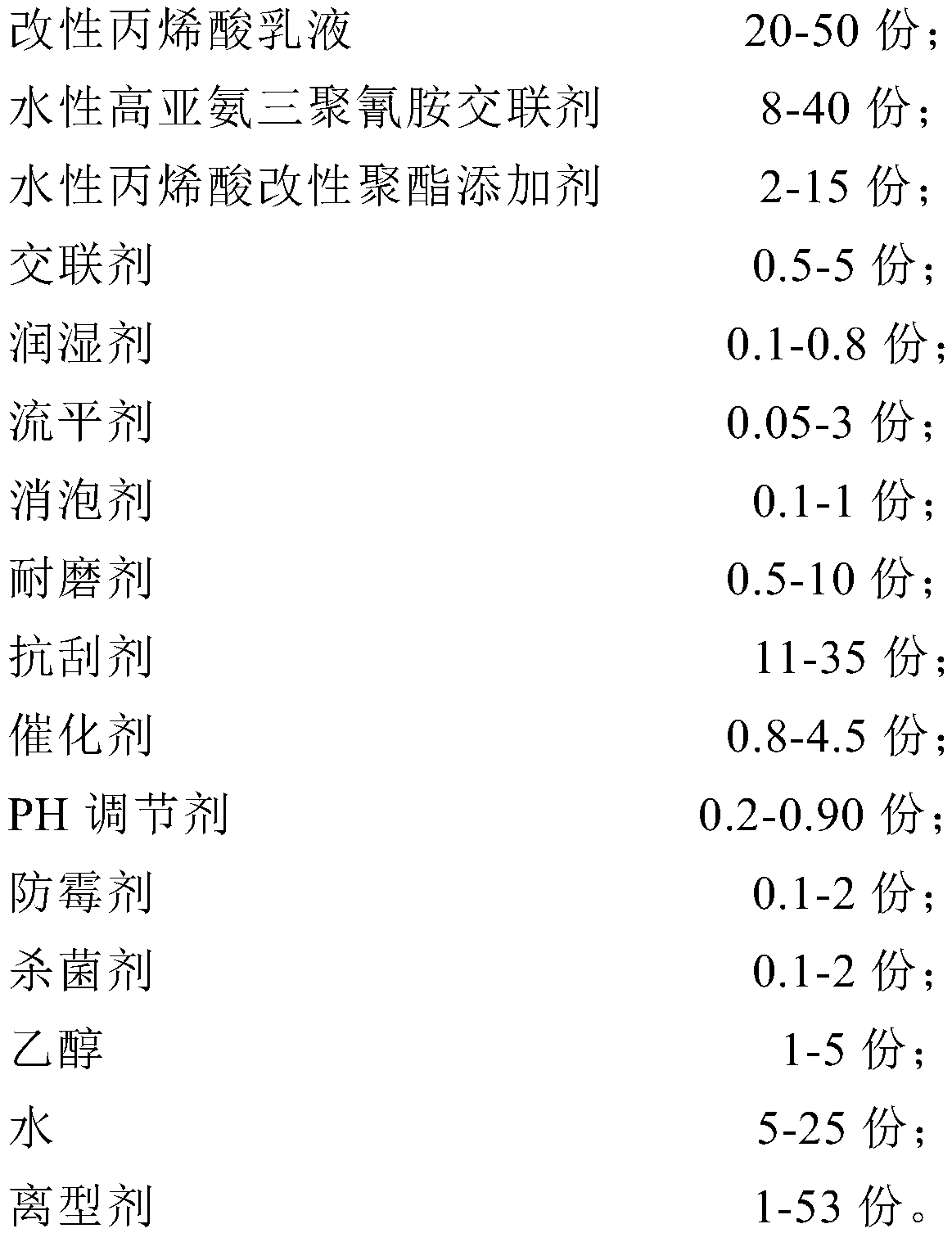

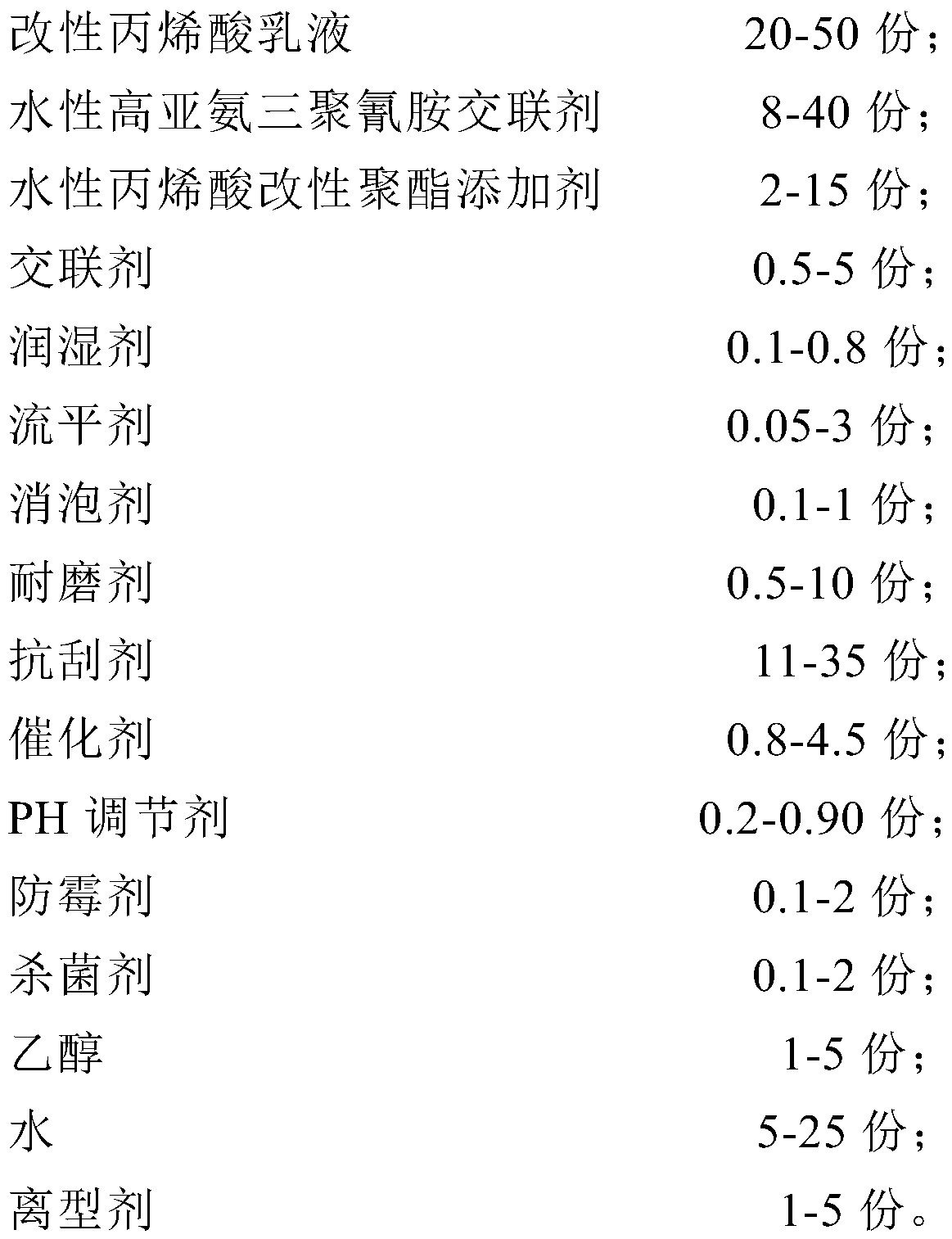

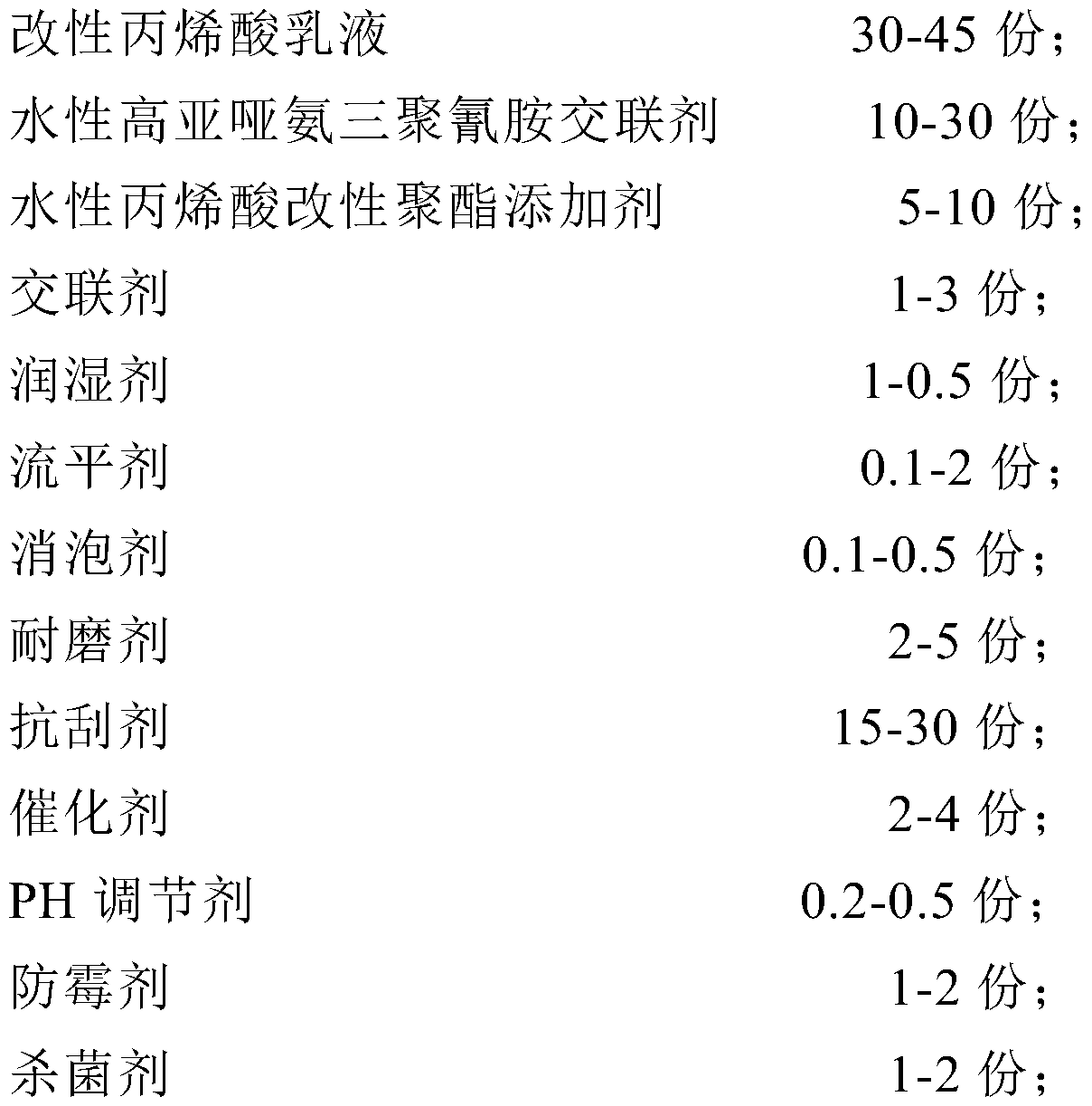

Method used

Image

Examples

Embodiment 1

[0054] This embodiment discloses a water-based gravure printing anti-scratch and wear-resistant varnish applied on the surface of panel furniture paint-free veneer paper, including the following components by weight: 45 parts of modified acrylic emulsion;

[0055] 10 parts of water-based high dumb ammonia melamine cross-linking agent; 5 parts of water-based acrylic modified polyester additive; 1 part of cross-linking agent; 0.8 parts of wetting agent; 0.05 parts of leveling agent; 0.9 parts of defoaming agent; 20 parts of anti-scratch agent; 3 parts of catalyst; 0.2 part of pH regulator; 0.15 part of antifungal agent;

[0056]The crosslinking agent is blocked isocyanate, the wetting agent is polyether modified polyorganosiloxane, the leveling agent is polyether modified polyorganosilicon, and the defoamer is polyether modified organic Silicon emulsion, the anti-wear agent is polytetrafluoroethylene wax emulsion. The anti-scratch agent is ultrafine glass powder, the catalyst i...

Embodiment 2

[0069] This embodiment discloses a water-based gravure printing anti-scratch and wear-resistant varnish applied on the surface of the paint-free veneer paper of panel furniture, including the following components by weight: 25 parts of modified acrylic emulsion;

[0070] 20 parts of water-based high dumb ammonia melamine crosslinking agent; 10 parts of water-based acrylic modified polyester additive; 5 parts of crosslinking agent; 0.2 part of wetting agent; 0.8 part of leveling agent; 0.5 part of defoamer; ; 15 parts of anti-scratch agent; 1 part of catalyst; 0.8 parts of PH regulator; 0.15 parts of antifungal agent;

[0071] The crosslinking agent is blocked isocyanate. The wetting agent is polyether-modified polyorganosiloxane, and the leveling agent is polyether-modified polyorganosiloxane. The defoamer is a polyether modified silicone emulsion. The anti-wear agent is polyethylene wax emulsion. The anti-scratch agent is ultrafine glass powder and PMMA. The catalyst is P...

Embodiment 3

[0084] This embodiment discloses a water-based gravure printing anti-scratch and wear-resistant varnish applied on the surface of panel furniture paint-free veneer paper, including the following components by weight ratio: 30 parts of modified acrylic emulsion; water-based high dumb ammonia 15 parts of melamine crosslinking agent; 8 parts of water-based acrylic modified polyester additive; 2 parts of crosslinking agent; 0.1 part of wetting agent; 0.3 part of leveling agent; 0.2 part of defoamer; 25 parts; 2 parts of catalyst; 0.6 parts of pH regulator; 0.05 parts of fungicide; 0.25 parts of bactericide; 2 parts of ethanol;

[0085] The crosslinking agent is blocked isocyanate. The wetting agent is polyether modified polyorganosiloxane and fluorine modified acrylic acid. The leveling agent is polyether modified polysilicone. The defoamer is a polyether modified silicone emulsion. The anti-wear agent is polyethylene wax emulsion and polytetrafluoroethylene wax emulsion. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com