Novel heat-resistant polyurethane hot melt adhesive for lamp industry and preparation method thereof

A polyurethane hot melt adhesive, a new type of technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of affecting production efficiency, short opening time, affecting appearance, etc., and achieve easy access to raw materials and equipment The preparation method is simple, and the effect of improving aesthetic problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

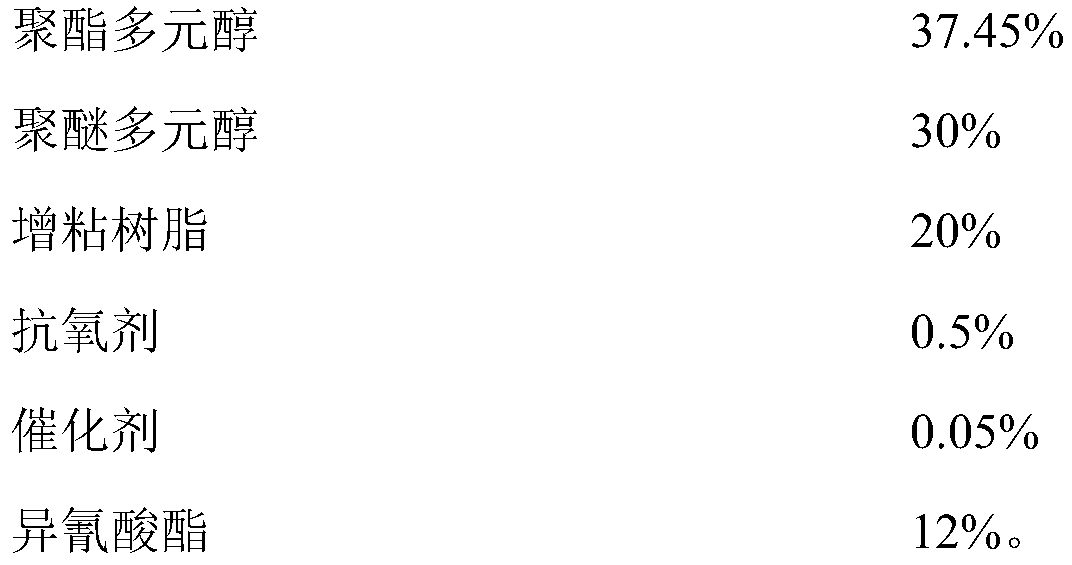

[0027] This embodiment provides a preferred novel heat-resistant polyurethane hot-melt adhesive for the lighting industry, including components and weight percentages as follows:

[0028]

Embodiment 2

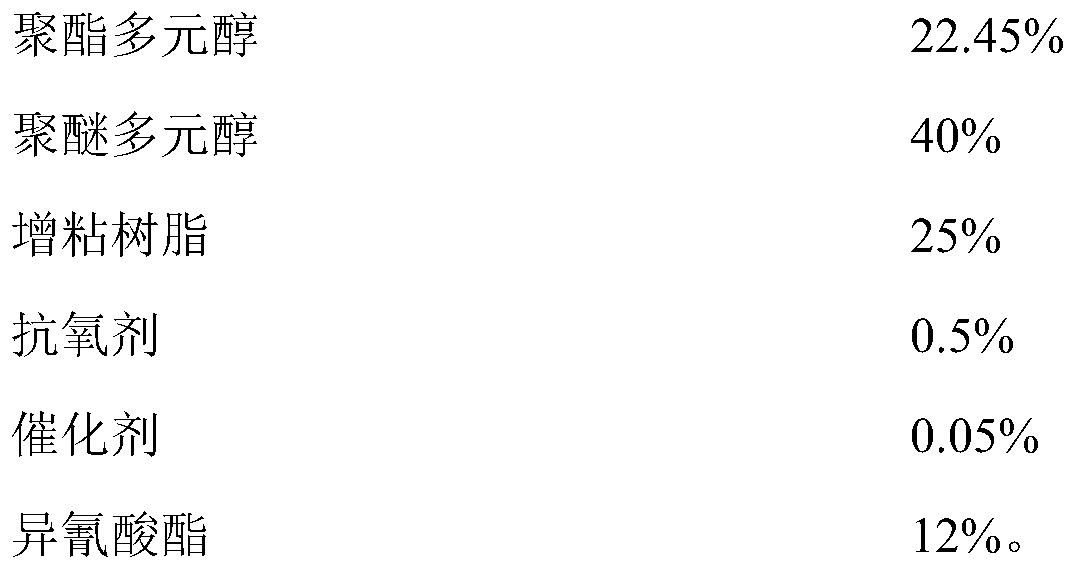

[0030] This embodiment provides a preferred novel heat-resistant polyurethane hot-melt adhesive for the lighting industry, including components and weight percentages as follows:

[0031]

Embodiment 3

[0033] This embodiment provides a preferred novel heat-resistant polyurethane hot-melt adhesive for the lighting industry, including components and weight percentages as follows:

[0034]

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com