Ultrafine modified magnesium hydroxide flame retardant and preparation method thereof

A magnesium hydroxide and flame retardant technology, applied in chemical instruments and methods, dyed organic silicon compound treatment, dyed low-molecular organic compound treatment, etc., can solve the problem of reducing the impact resistance of materials, poor compatibility of matrix resins, and material flexibility Loss of resistance and other issues, to achieve high flame retardant efficiency, good affinity, the effect of small physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The second aspect of the present invention provides the preparation method of the superfine modified magnesium hydroxide flame retardant as described above, comprising the following steps:

[0058] (1) Add surfactant, activator, and dispersant to ethanol, then heat to 40-80°C and stir to dissolve to obtain solution A;

[0059] (2) dissolving the magnesium salt in water to prepare a 1-5mol / L magnesium salt solution;

[0060] (3) Add the magnesium salt solution dropwise to the aqueous solution of 1-3mol / L alkaline precipitant to ensure that the pH of the system during the reaction is greater than or equal to 10. After the reaction, add solution A dropwise at a temperature of 40-80°C , stirring at a stirring speed of 400-600r / min, followed by suction filtration, washing, and drying at 100-110°C to obtain a modified magnesium hydroxide flame retardant;

[0061] (4) Add the modified magnesium hydroxide flame retardant to a super pulverizer for pulverization to obtain an ult...

Embodiment 1

[0066] Embodiment 1 provides a kind of superfine modified magnesium hydroxide flame retardant, comprises the preparation raw material of following parts by weight: 40 parts of alkaline precipitant, 25 parts of magnesium salt, 7 parts of activator, 10 parts of surfactant, dispersion 2 doses.

[0067] The alkaline precipitating agent is sodium hydroxide.

[0068] The magnesium salt is magnesium chloride hexahydrate.

[0069] The activator is sodium hexametaphosphate.

[0070] Described tensio-active agent is the mixing of calcium stearate, polyvinyl alcohol.

[0071] The mass ratio of calcium stearate to polyvinyl alcohol is 1:2.5.

[0072] The dispersants are KYC-913 and KYC-9.

[0073] The mass ratio of KYC-913 and KYC-9 is 1:0.7.

[0074] A kind of preparation method of superfine modified magnesium hydroxide flame retardant as described above, comprises the following steps:

[0075] (1) Add surfactant, activator, and dispersant to ethanol, then heat to 60°C and stir to ...

Embodiment 2

[0080] Example 2 is basically the same as Example 1, except that it includes the following preparation materials in parts by weight: 30 parts of alkaline precipitant, 20 parts of magnesium salt, 6 parts of activator, 8 parts of surfactant, and 1 part of dispersant.

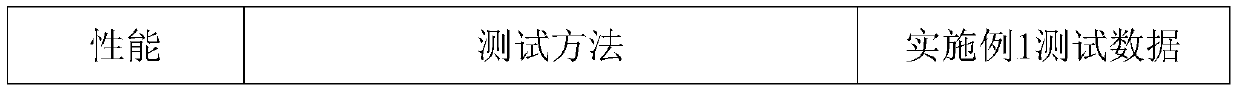

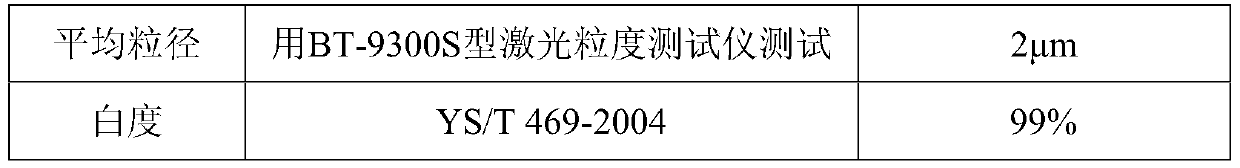

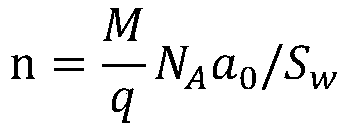

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com