Liquid detergent composition suitable for automatic feeding of dish-washing machine

A liquid detergent, automatic feeding technology, applied in the direction of detergent composition, organic detergent composition, surface active detergent composition, etc., can solve the problems of high humidity and storage temperature changes in dishwashers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this example, a liquid detergent composition was formulated. For the specific composition of the liquid detergent composition of this embodiment, please refer to Table 1, and the percentages in Table 1 are all percentages by weight. Among them, the rheology modifier is first added to deionized water, stirred and dispersed evenly; then non-ionic surfactant, alkaline additives, chelating agent, dirt dispersant, corrosion inhibitor, co-solvent are added in sequence, and then adjusted pH; then add preservatives, flavors, enzyme preparations and pigments in sequence, and finally fully stir evenly to obtain a liquid detergent composition.

[0051] Table 1. Liquid detergent composition formulations of various examples

[0052]

Embodiment 2

[0056] In this example, according to substantially the same method and conditions as in Example 1, a liquid detergent composition was prepared. Please refer to Table 1 for the specific composition of the liquid detergent composition of this embodiment. The difference is that, in this embodiment, the addition of sodium hydroxide is 0.5%, and the chelating agent selects 5% sodium citrate and 10% sodium gluconate; the addition of protease is 3%, and the addition of amylase 1%. , the addition of Kathon is 0.5%, the addition of lemon essence is 0.05%, and the addition of pigment is 0.3%.

Embodiment 3

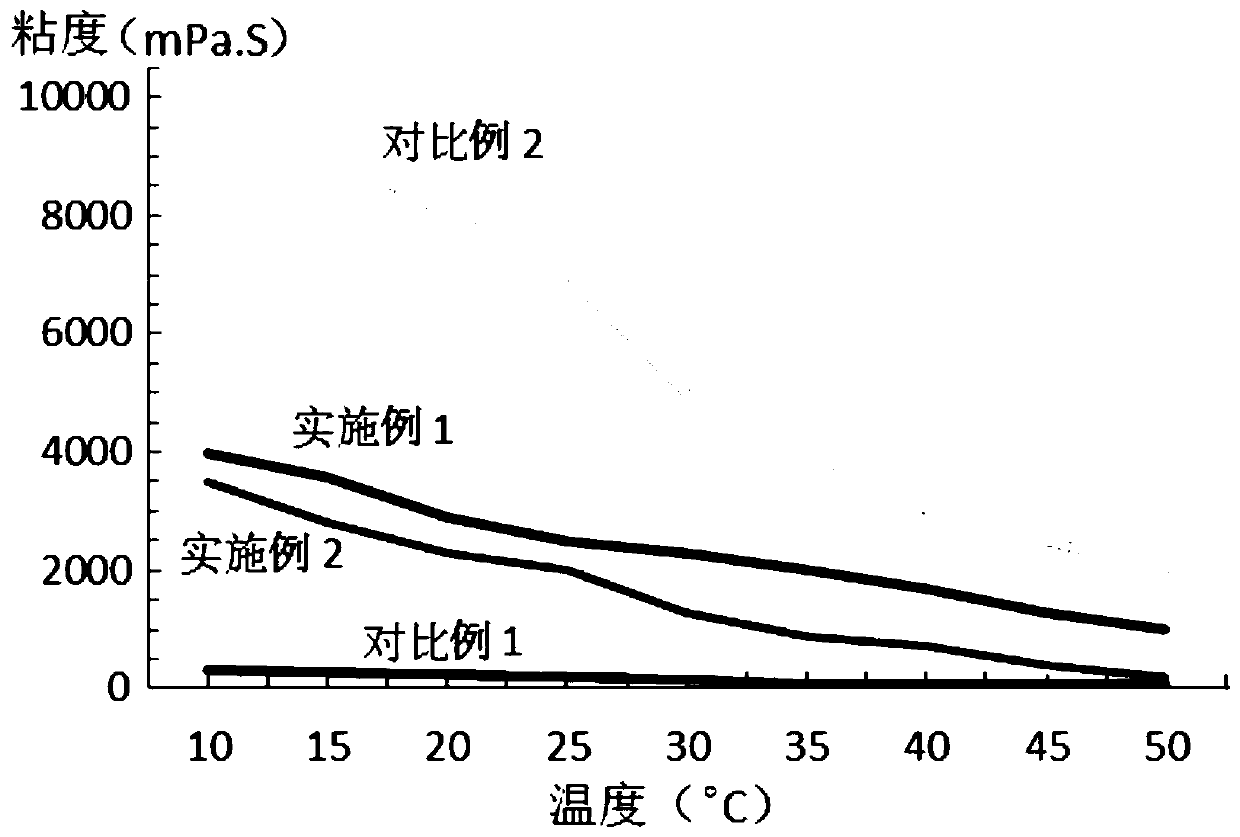

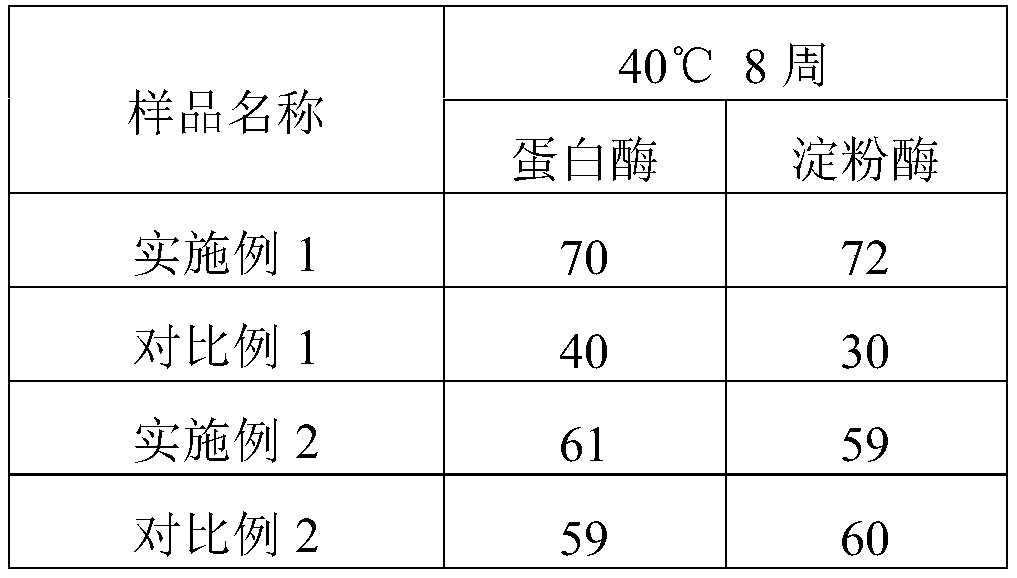

[0060] In this example, the liquid detergent compositions in Examples 1-2 and Comparative Examples 1-2 were subjected to a stability test, a viscosity change test, an enzyme activity test and a washing performance test, respectively. Among them, the stability test includes placing at 40 degrees Celsius for 8 weeks and repeated freezing and thawing 3 times; the temperature test range of the viscosity change test is from 10 to 50 degrees Celsius; Enzyme activity test of protease and amylase; washing performance test According to the GB / T24693 standard, the washing performance level and tea stain cleaning score are tested.

[0061] In this example, refer to Table 2 for the stability test results of 4 liquid detergent compositions. As can be seen from Table 2, the stability of the liquid detergent compositions of Examples 1 and 2 is better, and there is no problem of gelling, delamination or precipitation; but, the high and low temperature stability of Comparative Example 1 is all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com